Everyone is getting familiar with 3D Printing and the new technologies that are evolving with its help. Businesses have started using 3D Printing for their product manufacturing or prototype designing. Thus it is an additive manufacturing method. Aren’t you excited to know more about 3D laser printing?

3D Printing is such a hot topic in the industry that intrigues almost every industry, right from fashion or food to architecture and more.

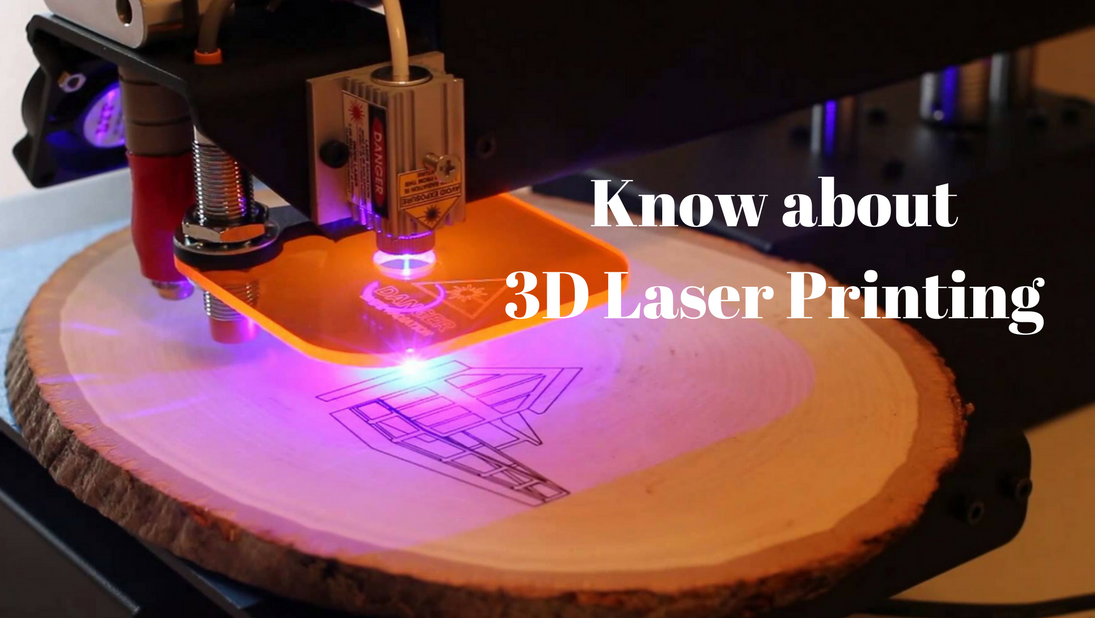

Whereas, Laser 3D Printing is where a laser beam helps to create a prototype or a product in a more precise manner. Thus it’s a whole new level of 3D printing itself. It provides a big help for the manufacturing industries to create exact prototypes.

What is 3D Laser Printing?

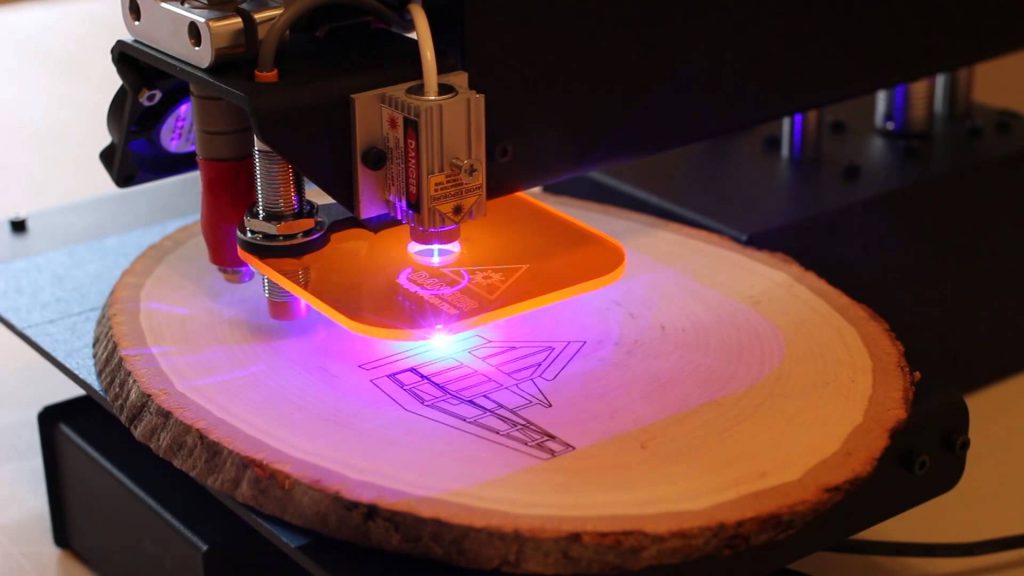

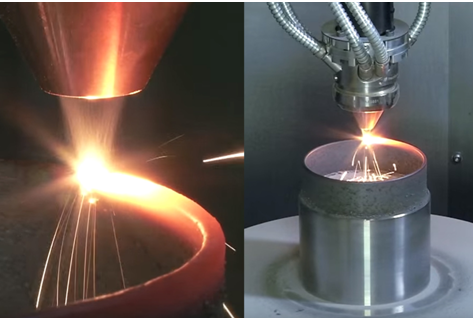

It is all about Subtractive manufacturing technology and laser added direct metal tooling. Therefore, which helps to form complex parts using high power laser and metal powder. Unlike normal 3D Printing, 3D Laser printing uses a beam thinner than a human hair to print a whole new object. The laser beams have the power to cut, shape and engrave 3D Printed parts.

They have common working capabilities like CNC milling. But like CNC milling, the 3D laser printer doesn’t have a milling head. They are all in one printer yet with some limitations. These printers are expensive as they include a 3D printer, a 3D scanner, a laser engraver, and/or a CNC mill.

What is Selective Laser Sintering?

3D Printing being a vast industry, it has many processes that are still not that common or known just like 3D Laser printing, SLS. Selective Laser Sintering is a part of 3D Laser Printing is an additive manufacturing method. It’s a powder bed fusion method where nylon is transferred from the container holding fresh powder material onto the build stage. In the process chamber with a recoating tool. A laser then selectively scans the thin layer of powder, sintering together powder particles. Hence, in the shape of the cross-section of the first layer of the 3D part.

Glowforge is a magical printer- Best Printer

Dan Shipiro a former CEO of Google wanted to make the laser technology more usable. The aim of Glowforge- an all in one laser 3D printer is to create more beautiful things. By giving the objects proper shapes and cuts. The company says it can cut wood, fabrics, leather, paper, linoleum, food, and even some plastics and also engrave metal and glass. It aims to help artisans and businesses to create innovative products just using one machine. The initial price of the printer with pre-order with a discount is $3995 and this is a cheap 3D Laser Printer.

Cost-cutting is also something that the Glowforge developers. Therefore, they are focussing on thus substituting the hardware components with sophisticated software. For a simpler design, there are no buttons on the Glowforge interface. Also, a camera inside the laser cutting chamber and image processing in the cloud will take the place of a motion planner. Therefore, which usually determines how the laser cuts the material.

There was a Glowforge Kickstarter project funded for a month in 2015 which was very successful and lead to many people taking interest in a laser printer.

Conclusion: Scope of laser 3D printing

3D laser printing is also becoming popular just like normal 3D Printing and is used for personal as well as industrial use. Many 3D printer manufacturers are creating Laser printers as they perform well and are all in one. Post-processing becomes easy with the Laser printers thus reducing your work.’

3D Laser Printing is a new wave in this Ocean of 3D Printing!!

Credits- all3dp.com,sharehack.com,youtube.com