Assembly & Set Up

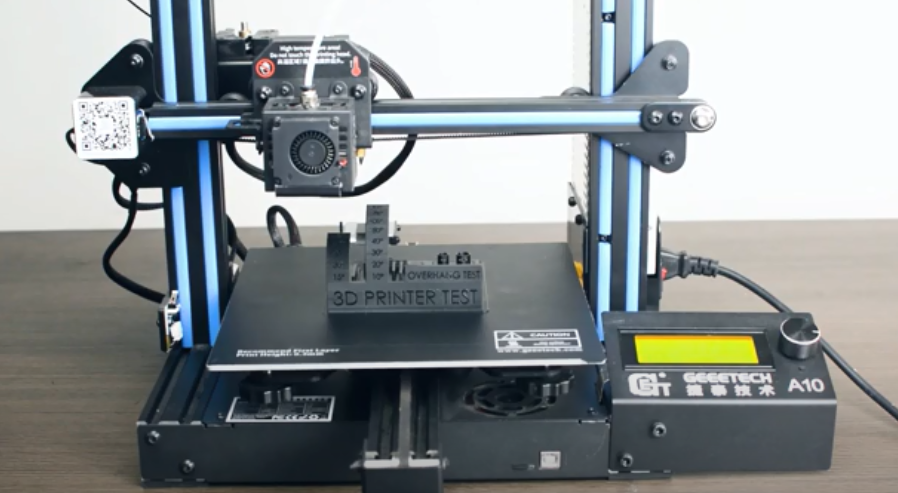

Set up your 3D printer as per the instructions. No matter how experienced you are, your vendor supposedly knows the products better than you do. It is recommended that you use parts, software, and materials from the same brand wherever you can to get the best experience. Remember, every 3D printer has its characteristics. Be open to some trial and error down the road.

Software Update

Keep your system up to date. Manufacturers and slicer companies are constantly experimenting with their software and firmware to fix bugs and improve performance. If your machine features an automatic update, enable it.

Maintenance

Perform regular maintenance and calibration on your 3D printer: Form and maintain a routine of checks; keep your filaments from moisture and dust; calibrate the bed.

Supports

Bear in mind the 45-degree rule and 5mm rule. Any overhangs of above 45 degrees(or 60 degrees depending on your printer) may require supports. Just like overhangs, not all bridges require support. Consider supports only when the bridge is more than 5mm long. “Rafts”, and “brims” are great support tools to increase adhesion. Add support structures to your design for any steep overhanging features or models that have a small base.

While supports are great for some cases, you may want to avoid them, for the following reasons: first, they consume extra filament; second, the print takes longer time; and finally, removing the support structure of the print can be a pain. If you are still not sure whether you need support, run a test print to find out. You can also use your creativity to make the support structures part of your design, in case you think them necessary. Ways to circumvent supports: reorient your model; reduce the overhang angles; and split your model into smaller parts.

The first layer

Your first layer is the foremost important layer of your print. Make sure it sticks well to the bed. Again, support structures, a heated bed, and glue all are great tools to help with adhesion.

Details

Examine the details of your model. Are there any tiny projections or parts that are too small to print on a desktop 3D printer? In your printer, there is a very important but often overlooked variable, that is the line width, which is determined by the diameter of the printer nozzle. Most printers come with a nozzle of 0.4 mm or 0.5 mm in diameter.

]]>

Layer shifting, in other words, known as layer misalignment, is when the layers of the print are not properly aligned, and the print can be unsightly(mostly a failure). It is a common issue in 3D printing and can be tricky, especially if you are a newbie. This article will walk you through the possible causes of the problem and how to fix it accordingly.

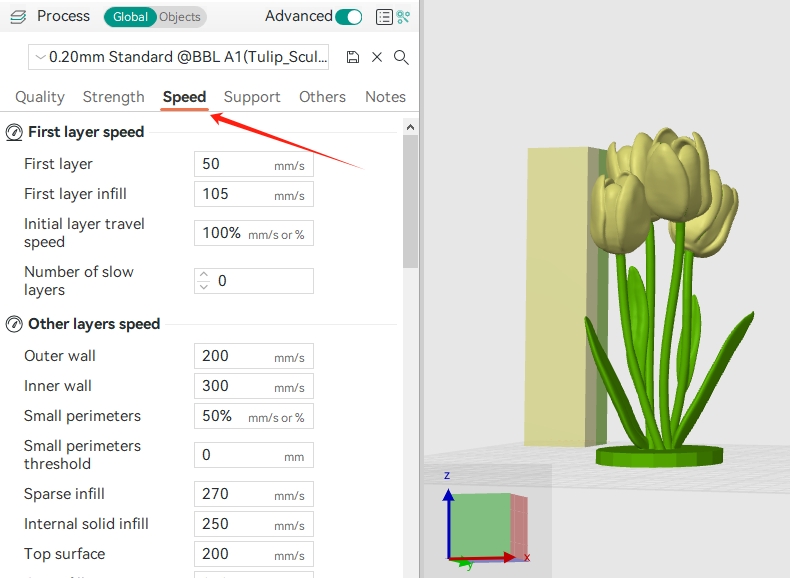

Nozzle setting

(1) The 3D printer nozzle is moving too fast.

To save time, some people are inclined to set the speed of the print job higher than what the driver motor is capable of, causing the tool head to fail to reach the desired position.

Solution: In your slicer software, set the speed at 40 to 60mm/s. Alternatively, you may adjust your speed by turning the knob, if you do not wish to stop your print.

(2) Nozzle deviates from the desired position

This happens when the extruder is traveling from one point to another of the print without the Z axis elevating the tool head. The nozzle then hits the object and is pushed away from its intended position. Because the system is unable to detect the deviation, it will continue with the print job, resulting in layer shifting.

Solution: In the settings, readjust the Z- offset to 0.3mm

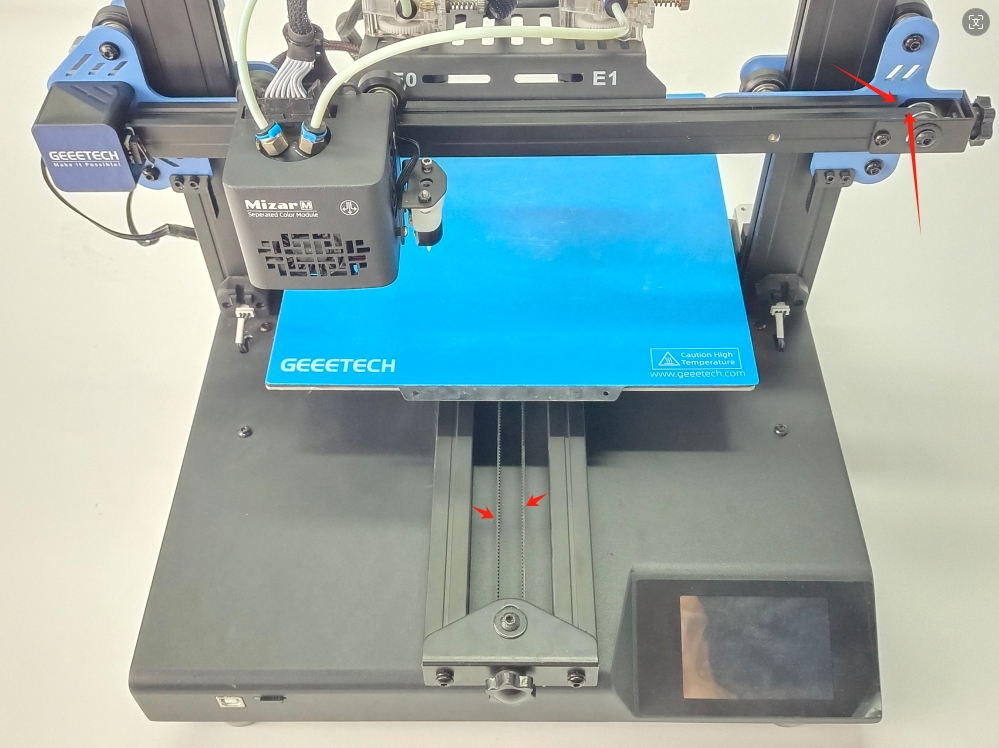

Mechanical disorder

Most 3d printers use belts to let the motor control the position of the nozzle. Over time, the belt may stretch, which can impact the tension used to control the nozzle. If the tension becomes too loose, the belt may slip on the pulley, which means the pulley is rotating, but the belt is not moving. If the belt is too tight, this can also cause problems. Tightened belts can create excess friction in the bearings that will prevent the motor from spinning. Ideally, the belt is installed tight enough to prevent slipping, but not too tight to stop the system from rotating.

Solution: manually adjust the belt for proper tension. Regularly check and maintain your 3D printers.

Layer shifting could also occur when the motors fail to spin as a result of not getting enough electrical current; or when the model exceeds the size of the print bed, which causes the nozzle to lose its position at the edges. Finally, make sure there is no external force imposed on your printer, for any level of external force could interfere with the moving of the belts.

Any questions or ideas? Leave us a comment in the comments section or email us. We would love to hear from you.

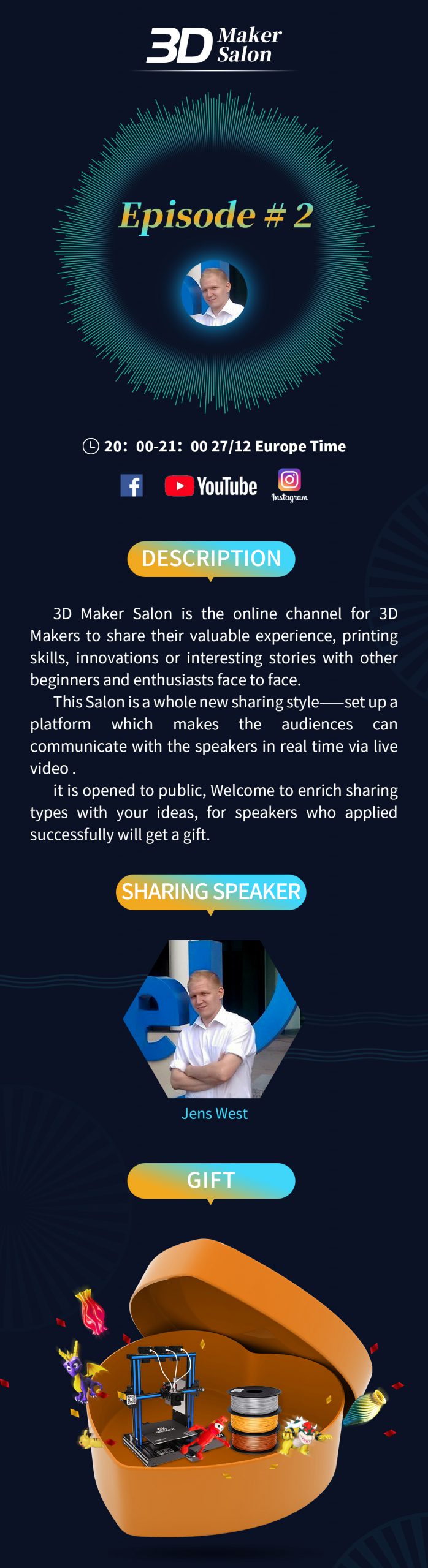

]]>I hope you all enjoyed the 1st episode of 3D Maker Salon by “Andreas Braun” who is well-experienced in 3D printing and worked with them for a quite long period. And also known as Co-owner at Geeetech. So I hope it was great listening to him through his journey in the 3D Printing World, skills, tricks and turns with his experience. If you have missed to watch it then here is the link just click on it and enjoy him speaking. Live streaming link of 1st episode: Click to watch

Here comes 2nd episode of 3D Maker Salon with a new speaker “Jens West”. I already mentioned he is being worked for a long period with 3D printers. He is going to share a lot about the 3D printer filaments and his experience with them isn’t it interesting. Then what are you waiting to mark the date and time on your calendar, complete all your works before he is LIVE? Enjoy listening to him and try them out, let us know was it worth watching.

Live Stream: 8:00 pm-9:00 pm Dec 27 -EU Time

Live link: https://bit.ly/2PlgWC9

Merry Christmas to all and here comes a big surprise from Geeetech for Merry Christmas & New Year. Aren’t you guys excited to know what is your surprise gift. Then let me tell you, come close so that no one should hear it and grab the special gift from you.

There will be a Lucky Draw from the audience who is watching the whole event. The lucky audience will get a New Year Special gifts then what are you waiting to mark the date and time of the Live streaming event on your calendar. Hence, complete all your works before it starts and win exciting gifts.

You can also be a speaker if you’re interested to share your experience, skills or innovations related to 3D printing. Therefore, it is a platform for 3D hobbyists and to encourage them. There is also a surprise gift for the Speaker than there is only one step. That can get you a gift, you just need to fill the form.

?Be the speaker, get one A10T

For more information, please visit: https://bit.ly/2PMYgdA

Now let me thanks the audience for making this event a grand success and help us to provide the knowledge related to 3D printing. In the same way without any hurdle in the upcoming episodes of 3D Maker Salon- Geeetech.

Make the best of Geeetech 3D printer only @ Geeetech official site

]]>