If you’ve been using an FDM printer, then you’re no stranger to the fact that getting your print to stick to the bed and then consequently getting it to come off- is a frustrating task.

Some of the common surface materials that people use are – blue painter’s tape, straight glass plates, and even glue sticks to the surface of the print bed, which prevents warping when printing in ABS filaments.

However, apart from these, there are some seriously useful ways to ensure even the most stubborn objects get off the build plate! Interested? Then read the below tips.

Use More Force

Usually, while removing a 3D-printed object, we handle it carefully and remove it from the platform as gently as we can. But if it doesn’t come off easily, more force is needed.

If the object is sturdy you can go ahead and put in more strength. Grabbing, twisting, and turning, should work in most cases.

You can take out the build platform and try to hit the object sideways very carefully with a rubber mallet or something similar. If the object gives you a small gap to slide in the tip of a screwdriver, a light tap on the handle provides a lot more force than you can, and the print should pop off.

Make Use of Temperature Difference

After the print has finished, let the printer and the heated bed cool down completely. If you’re lucky, the print will pop right off after a while. If not, you can utilize the fact that the material properties of the plastic and the print platform – glass, aluminum, or also plastic – are different.

By using more extreme temperatures you can take advantage of this behavior. You can speed things up by placing a cool pack or running cold water on the 3D print. Putting the build plate with the object in the fridge or freezer for half an hour works in many cases, too.

Use a Blade

Think of all the flat, sharp tools that you can slide between the printed object and the build platform. Spatulas, a palette knife, or even a razor blade will be able to help you pry away your design from the print bed.

Use these sharp objects with extreme caution and preferably use a blade with a handle on it. You can even opt for special scraper blades designed specifically for the task of removing 3D prints from the bed.

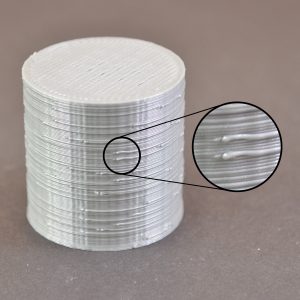

The disadvantage of this method is that you will most likely damage the surface. It’s possible that you may cut the upper layer and create some wrinkles in the surface which can cause problems with the next prints.

Solve it with Solvent

Using solvent liquids should be the last resort since they will make a new coating of blue tape inevitable. You can try putting a bit of isopropyl alcohol around the edges of the print and let it soak through the tape. Getting the print-off will be easier. If in doubt, you can take off the whole tape.

On build plates where you used a glue stick, for example, warm water can do the trick.

Floss It Out

Dental floss isn’t just for your teeth! It can help remove stuck print asides as well. Place the string underneath the edge of the print and begin to move it horizontally in a sawing motion.

Depending on how much the print is stuck actually, you may need to do this along with the whole bottom. The good thing is, that this could leave your taping intact and works on all kinds of other build platforms.

Buy a Flexible Build Platform

Sick of all these methods that make nothing better? You should switch to a build plate that is flexible. A simple twist and any print falls off.

Flexible build platforms are available online available in many custom and popular sizes. Company Zebra Printer Plates and Fleks3D provide flexible build-plate that fits most printers.

Geeetech Superplate 3D Printer Glass platform

To wipe out the big headache of removing the print from the building platform, the Geeetech Superplate comes with a high-performance microporous coating and silicon carbide glass. The silicon carbide glass is of chemical stability, uniform heat, and durability. Besides, the special coating is inorganic, with a hardness of 8 Mohs and heat resistance up to 400 ℃. Easy to clean with water or alcohol. Compared with aluminum plates, this kind of build platform is of better adhesion and flatness and easy to take off prints.

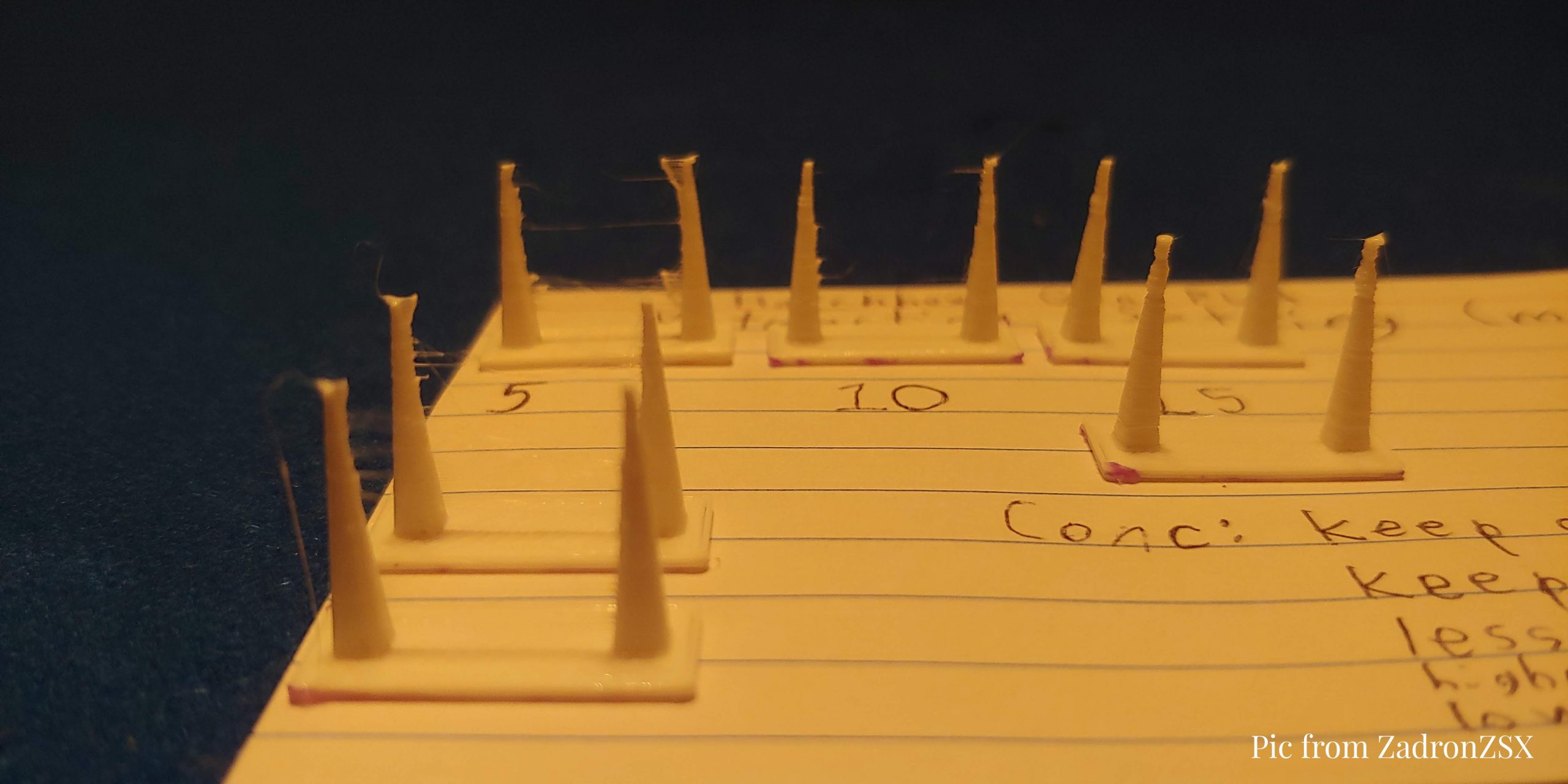

The first picture shows Geeetech Superplate glass platform and the second one Geeetech Superplate 3D Printer Aluminum Heatbed Kit .