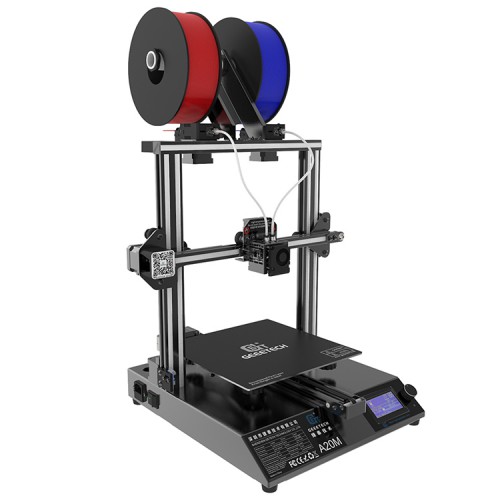

Just like any other equipment, 3D printers also require good care and regular maintenance to produce top-notch results. Compared to traditional printers, 3D printers are easier to operate and maintain. This article will discuss how to perform routine maintenance on your 3D printer.

Routine check for printer

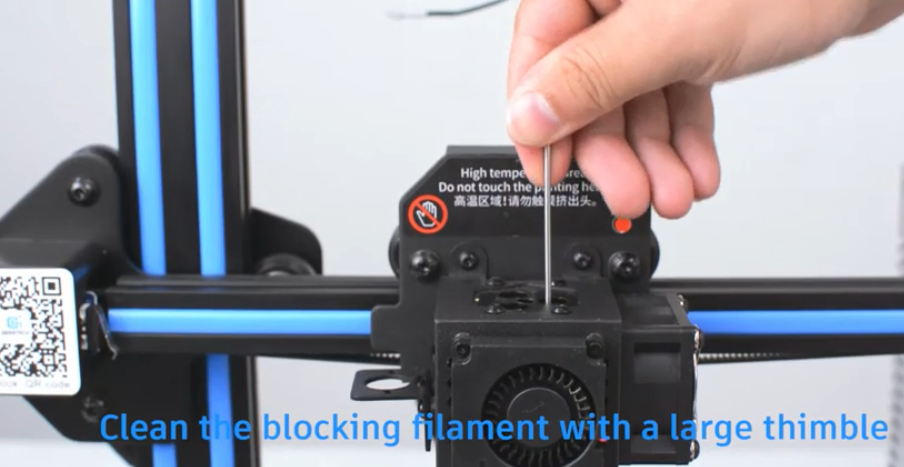

Prior to your print: make sure to form and follow a routing of checks: whether the nozzle is blocked or broken, or the traps are loose;whether the motor bearing and linear rails are in want of oil, whether the platform is calibrated, clean,and etc. Ensure that a clogged nozzle is fixed; any broken or aging components are replaced in time, lubricating oil are added regularly; and that loosened nuts are tightened.

Inspection during Printing

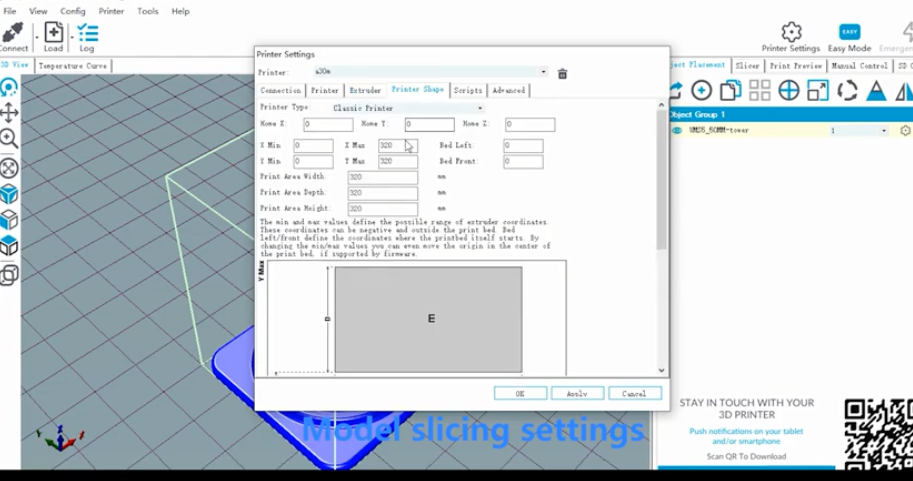

During Printing: parameter settings should not exceed the recommended range for your printer, otherwise, desired objects would not be printed, and problems such as too high a nozzle/bed temperature or excessive load would damage the machine. Shut down the system when a problem has been detected, and only resume printing after the problem has been fixed. When removing the 3D print, do not use brute force or any object that could damage the print bed.

Double-check after printing

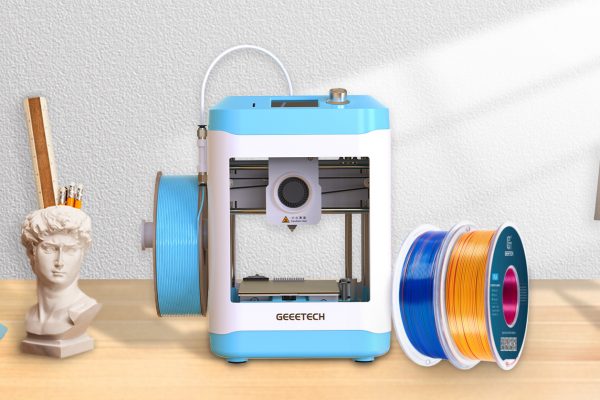

Finally, after printing, repeat step one: remove any sign of dirt on the nozzle, print platform, guide rail, motor, fan, and other parts of the 3D printer so that it does not accumulate over time. Keep your machine and filaments in a dust-free, dry environment. Also, make sure the spools are not tangled.

Bonus tip: Use fewer brands of the 3D printing filament, it will harm 3D printers if we mix lots of brands’ filaments on them. The reason is that printers and filaments from different manufacturers differ to various degrees in their performance and features. For example, filaments you buy from Geeetech are pre-tested on Geeetech’s 3D printers, as a result, they work best with these machines.