Choosing your first 3D Printer can be exciting and yet extremely confusing. Especially since there are so many 3D printers available in today’s time. Endless hours of research and reading online forums will all tell you the same thing- It depends on what do you want your 3D printer to be used for.

Once you have that figured out, we come to the specifications and technicalities involved in finding a 3D printer to match your needs. Thus, here are the most important features which you should consider before buying your very own!

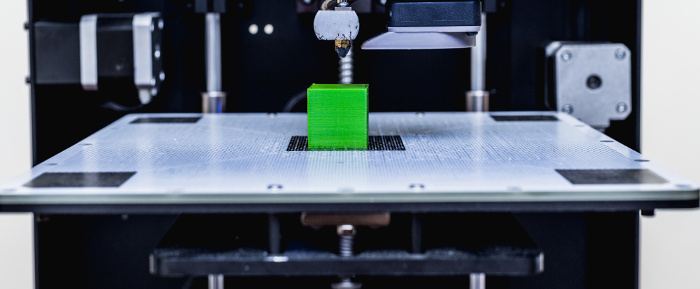

Build volume

The most important thing to consider while buying a 3D printer is the build volume. It is usually the first parameter given by 3D printer manufacturers. It determines the maximum size your printed model can be. It involves the length, width, and height of your printing consequently. So, initially think about the biggest thing that you might want to 3D print with your device, and reject all the 3D printers whose build volume is too small. Also- pay close attention to the units used. Some manufacturers use inches, others use millimeters or inches, so be careful.

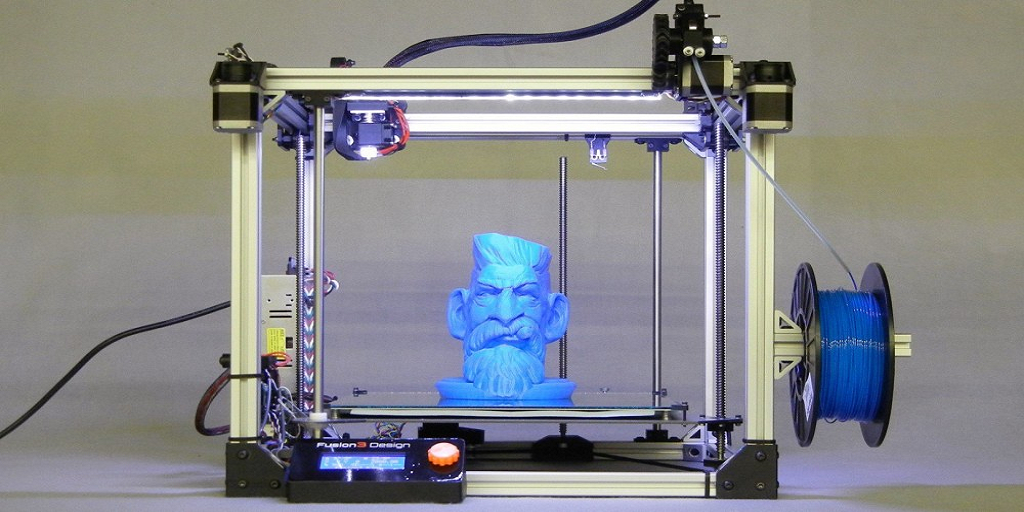

Build platform

One of the most important parts of a 3D Printer is the printing bed. It is the base on which the first layer of your printing is set up. There are many types of bed available in 3D printers but the main difference between them is whether they are heated or not. In this case, it is ideal to choose a heated bed. It is not a big expense, but most importantly it significantly improves the adhesion of your 3D printing to the bed, especially when using ABS material.

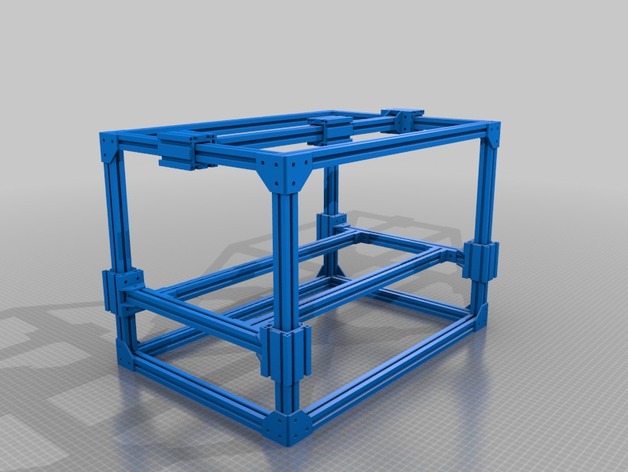

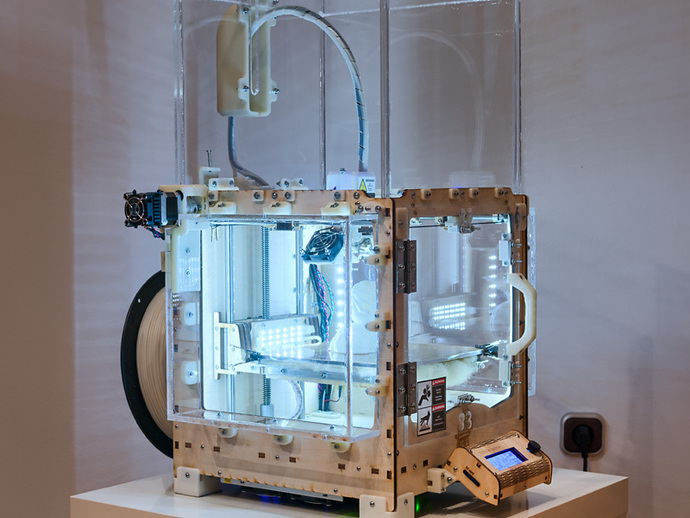

Frame stiffness

The frame is that part of the printer which holds your 3D printer together. Since your device’s extruder will move back and forth rapidly, look for machines with a decent, solid frame. The aim is to minimize the shaking of the whole machine, which is important to achieve good quality in your 3D prints. It is advisable to opt for frames built of metal parts only; if your budget is high enough you should avoid plastic joints since in most cases they make the construction wobbly.

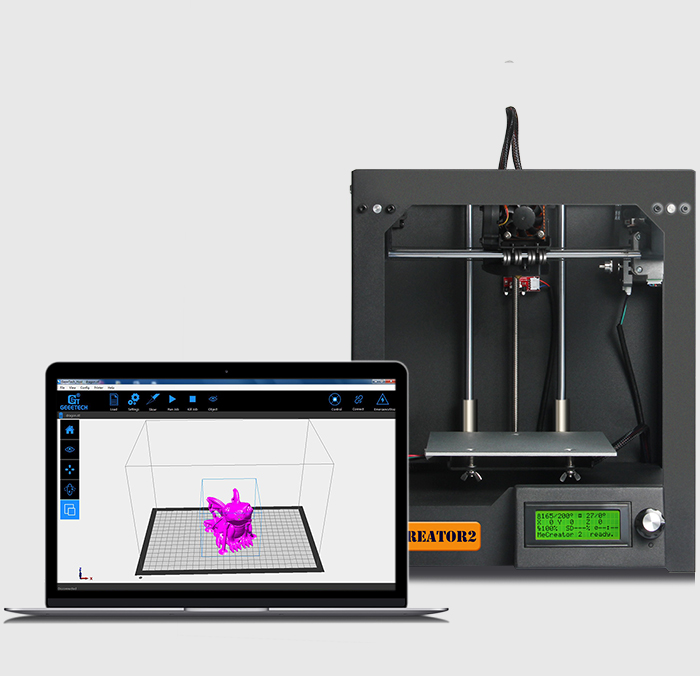

Printer software

We often don’t pay enough attention to software and it could turn out to be a big mistake, especially when you are not yet familiar with 3D printing. Many 3D printers use open-source software, and this is a cool thing. However, numerous parameters can be overwhelming for you at first sight if you are a 3D printing fresher. On the other hand, you could look for devices with dedicated software or even plug&play versions. This will certainly make everything easier at the beginning.

The number of nozzles

You’ll find that desktop 3D printers have one nozzle while industrial 3D printers have two nozzles. Where does the difference come from? You might think that the price is the answer, and that’s partially right, but, in fact, an additional nozzle is not only an unnecessary gadget. The first nozzle is used to produce the actual model, and the second one creates the support. When your 3D printer has one nozzle, both the actual model and the support are printed with the same material, and they stick together. As a result, the customer must spend additional time getting rid of this support material manually, and it doesn’t look nice. Using an additional extruder affords the chance to use dedicated water-soluble material which will disappear after putting your 3D printed model into the water for a couple of minutes.

The heated chamber

Just like the nozzles, industrial 3D printers have one while most of the desktop ones do not, except for a few. The reason why manufacturers use whole isolated and heated chambers in their 3D printers is mostly a phenomenon called ‘material contraction’. Materials can change in dimension according to the temperature and by making the environment in a 3d print chamber more stable, it can really affect the quality and repeatability of the 3D prints. Internal heating is not the not feasible for all, but you should at least make sure that your 3D printer’s interior is isolated in some way, or you should isolate it yourself; even cardboard can improve your printings.

Other numerical printer parameters

Last but not least, there are a few more parameters which the manufacturer can give in a printer description. These include the nozzle diameter, the z-axis single step, positioning, precision etc. They all affect the quality and precision of your 3D printed design.

We hope this article helped you understand what goes into choosing an ideal 3D Printer to make all your 3D printed designs a reality. Take a look at our Store and maybe you’ll find your dream 3D Printer!

Credits- 3Ders.org, Pinterest, 3dnatives.com 3dprint.com