- Require a lesser number of components

- Production of required components may be stopped

- Takes lots of time

- Traditional methods are costly when comes to produce a lesser number of components

- Can’t provide the rail operator with latest technology parts

- Lesser number of labor can cut the production cost to around 50%

Benefits of 3D printing for UK rail department

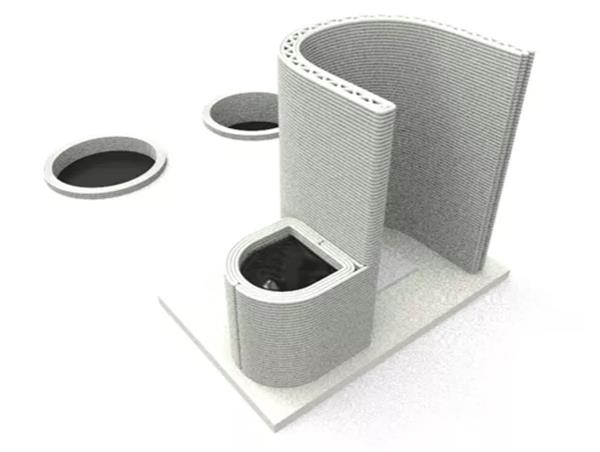

Deutsche Bahn Consultancy and Engineering service provider, Angel trains British rolling stock operating company, Stratasys is an American 3D printer manufacturer and lastly Chiltern Railways British train operating company their collaboration was first announced in December 2018 to produce 3D printed replacement parts for trains. As a result, UK has already announced becoming a world leader in the additive manufacturing sector by 2025.

Therefore, UK government has taken a step ahead by collaborating with these companies to manufacture passenger trains. The components such as armrests and grab handles using additive manufacturing 3D printing techniques. Hence, the company is looking for other applications, researching 3D printed seat tables and custom braille lettering abnormal passenger’s

3D printing technology is well utilized in Rail companies for customization. The 3D printed passenger train components are running successfully with seven grab handles that were produced within a 2 an half months and cutting the cost down from £15,000. Hence, the cost saving of 50% per part will be achievable.

The testing of other applications and research is carried out in 3D printed rail components. So, to provide a better journey for rail passenger’s in the future.

Make the best of Geeetech A10 3D printer only @ Geeetech official site

]]>

During the initial stages of 3D Printing, the whole object had to be printed using a single material. That’s impossible because you can’t print a house or fashion accessories with a single material. Thus Multi-material 3D Printing prints a single object with two or more filaments rather than just using PLA, ABS, or any other filament.

This is a bit tricky! You can use a dual extruder printer or get things done with a single extruder printer itself.

The question is how?

A Dual extruder has multiple extruders that allow you to have multiple filaments ‘piped in’ and ready to be used whenever the object being printed requires them, and this is where the saved time comes from. Having different filaments ‘ready to go’ means you no longer have to pause a print, empty out the extruder of the previous filament, feed in the next filament, and resume the print every time you need a different material. The printer will simply call on which filament it needs when it needs it.

While with a single extruder when you want to print a multi-material thing you have to replace the previous material with the other one and then print it. This takes time as 3D Printing prints layer-wise and if you have multiple layers of multiple materials then it requires a lot of time just changing the filament.

How to create a multi-material print with a Single Extruder printer?

The secret? Spread the different materials across different layers of a single extruder printer. Both of the models that are shown have the materials at separate heights; on separate layers. The process basically works by printing with one material to a certain height, pausing the printer, switching materials, and continuing the print.

Step 1: Choose your 3D Model

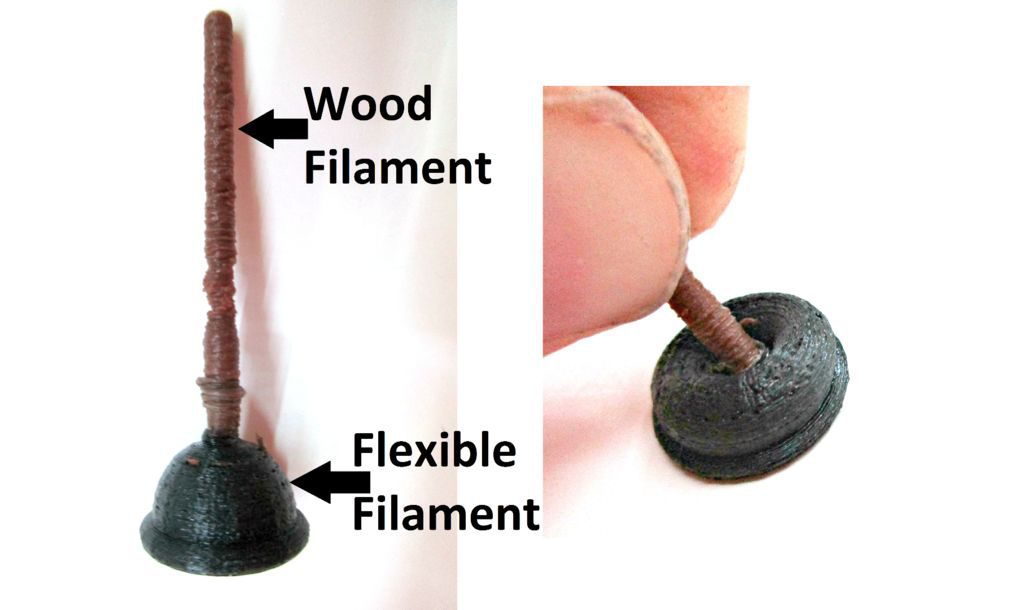

Icecats has explained this with really well with an example of printing a toilet plunger as it has a flexible filament and a wood filament.So you need to find a good 3D model from Thingiverse or MyMiniFactory or any other 3D Printing website. You need to keep certain things in mind like:

- Choose the object wisely which makes sense of carrying out a multi-material printing process.

- Keep a certain height within two materials as this is the key to the process like the flexible plungers base is lower than the wooden handle.

- See whether the model is printable with the desired materials.

Step 2: GCODE and other settings

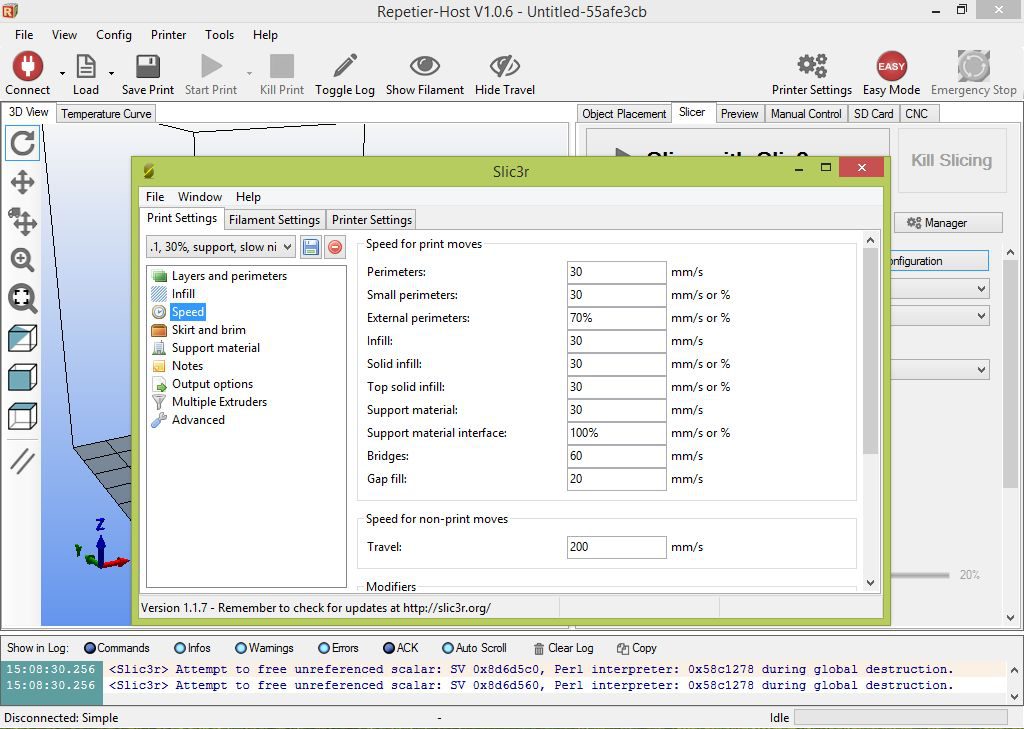

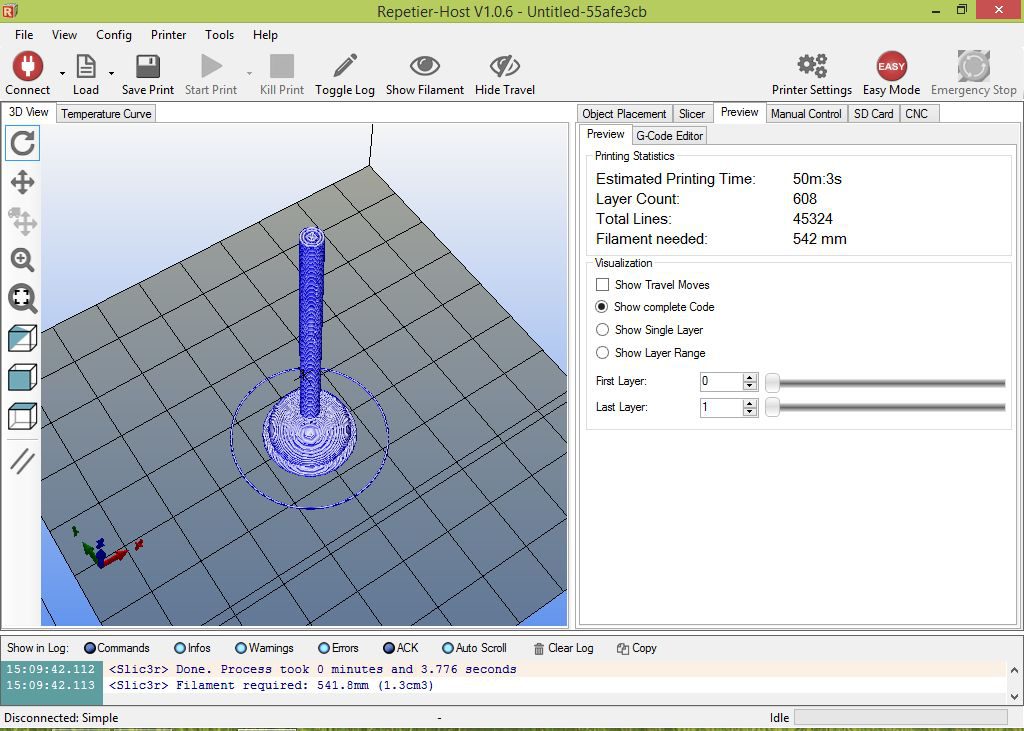

- Slice your 3D Model into a GCODE with your 3D Printers host software.

- Look up the speed settings into it and then set it up to the slowest.

- Find a proper balance of layer height, infill, and retraction settings for your prints.

- After you are ready, heat the printer and fill the first material into it. You can change the temperature later when you want to fill in the other material. The first material used by icecats was Ninjaflex.

Step 3: Switching materials

- Monitor the printer as the first material is extruded.

- When you want to switch the material, just pause the printer, it usually takes a bit of time for the printer to stop, raise the printer to 10 mm height on the z-axis.

- To prevent the leakage you need to place a piece of paper below the extruder. If necessary, adjust the hot end temperature in the Manual Control tab to suit the second material.

- Switch to your second material and purge the extruder until the new material comes out pure. Remove your piece of paper and continue the print. Repeat this process as many times as necessary.

Step 4: The Final Results

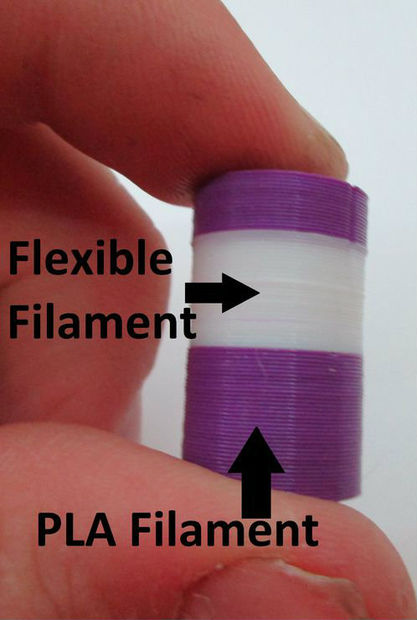

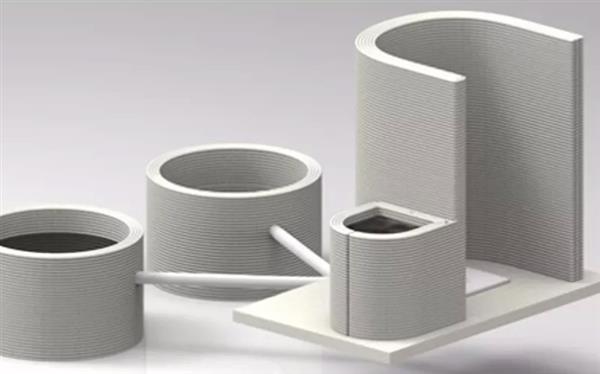

Icecats tells how his 3D Print resulted in, he basically used two different PLA/NinjaFlex and wood/NinjaFlex. He says that both tests worked well for him.The purple and white cylinder shown above was printed with PLA and NinjaFlex. He has stressed that the print until it broke- two PLA layers spit apart, which means that the NinjaFlex/PLA bond is actually stronger than the PLA/PLA bond! The bonding between the wood/NinjaFlex was similarly high strength.

Here are some other ideas for prints to try.

- hard PLA/ABS box with NinjaFlex hinge

- hard PLA/ABS model car with NinjaFlex shocks and tires

- wood “table” with PLA/ABS legs

Thus you can try multi-material printing with your single extruder printers as well and give your prints the real touch as you want.

Get these dual or single extruder printers for better prints and experiences of 3D Printing.

Credits: instructables.com.

]]>AM can be implemented throughout all of the steps of the manufacturing process, from creating prototypes and producing supporting tools like jigs and fixtures to end part production.

https://www.youtube.com/watch?v=XWFF8qr0pyo

Visual Prototypes

When it was invented, 3D printing was mentioned as rapid prototyping, a method for automating and reducing the labor required to create a prototype model for design validation. Since then, it has found use in a number of other applications, but the technology is still widely implemented to create visual models and functional prototypes.

For the production of visual models, 3D printing has evolved more. Though it’s possible to create highly detailed prints with technologies like stereolithography (SLA), full-color 3D printing with binder jetting, paper 3D printing, and material jetting can achieve a vibrancy impossible with other technologies.

ColorJet Printing

ColorJet Printing (CJP), a binder jetting technology from 3D Systems, involves the deposition of a liquid binding agent and CMYK inks onto a bed of gypsum powder, resulting in the creation of full-color, sandstone-like models. Though the process is different, PolyJet, from Stratasys, takes this a step further with the ability to alter physical properties such as flexibility and transparency. PolyJet is a material jetting technology that deposits photocurable resins, which are then hardened with a UV lamp.

Mcor’s paper 3D printer

Mcor’s paper 3D printing technology unable to achieve the same geometric complexity but the parts are made from paper, making it eco- friendly. This process sees CMYK deposited onto white paper, which is then pasted to the previous layer and cut with a tungsten carbide blade.

Functional Prototypes

For testing the function of a design, color quality may not be so important. For example, testing a living hinge might require 3D printing with a durable thermoplastic, such as nylon, or with a rubber-like photopolymer, printed with material jetting or vat photopolymerization technologies, such as SLA or digital light processing (DLP). For wind tunnel testing, a number of technologies work, but the part will need to be post-processed in such a way that aerodynamic properties of a part aren’t inhibited by the striation made through the 3D printing process. For this reason, a high-resolution technology may be preferred.

Alta Motors All-Electric Motorbikes

Alta Motors is an electric motorcycle manufacturer that has begun working to use 3D printing to prototype parts for its bikes. In designing the firm’s Redshift motorcycle, Alta Motors turned to 3D printing service bureau The Technology House (TTH) to iterate functional prototypes quickly for parts that were to be mass manufactured. TTH relied on continuous liquid interface production (CLIP), an ultrafast 3D printing process from Carbon, to 3D print a number of parts.

Tooling

As a design moves from the concept phase to the production phase, a manufacturing operation may implement 3D printing for the fabrication of custom tools that aid in the production process. This can include anything from guides for precise drilling, dies for forming or cutting the raw material into a specific shape and measurement tools, like gauges, to jigs and fixtures that hold a part in place while other operations are performed.

3D printing may be used directly or indirectly in the creation of tooling. In the case of indirectly fabricating a tool with AM, a tool may be made by coating a 3D-printed component in rubber, which is then used to cast the tool itself.

When tools are custom made for a new manufacturing job, a business may need a third-party service provider, which may rely on traditional manufacturing technologies, such as CNC machining, to create the tooling. This process can be costly and time-consuming, with the business waiting weeks to months for the tools to be shipped in order to even begin manufacturing.

Patterns, Core, and Molds

3D printing is also used to produce objects that will ultimately be cast in metal. On a small scale, this can mean lost-wax casting models for jewelry and dental crowns. On a large scale, this can mean creating sand cores for casting complete engine parts.

In the process of lost-wax casting, a positive is 3D printed in a castable material. It is then submerged in a specialty investment material and burned out in a kiln. The result is a mold that is filled with molten metal to create a metal part. SLA, DLP, and material jetting technology, like the wax 3D printing process created by Solidscape, are ideal for this process, as they are capable of producing finely detailed prints with a high burnout.

https://www.youtube.com/watch?v=15AmryIYu4k

For larger parts, binder jetting processes, like those from Voxeljet and ExOne, may be implemented to 3D print sand cores and molds. Binder jetting involves the deposition of a binder material onto a bed of powder, including sand, layer by layer until the print is complete. In sand casting, this object may then be placed into a molding box, which is filled with molten metal and, once cooled, broken apart to reveal the final metal object.

Due to the speed, quality and cost of AM, the technology is best suited for the production of specialty parts in smaller batches, rather than mass-manufactured goods. For this reason, end products that are made with 3D printing have usually been made that way for the good cause.

Credits: Google, discbum.com, engineering.com, youtube.com

]]>At the brand’s Fall-Winter 2018 show in Milan. Gucci designer Alessandro Michele sent models down the runway carrying duplicates of their own headless domes. Gucci may well be the hottest brand in the world. That suggests that its favorite maximalist trends. All-over prints, endless logos, animal pictures, embroidery—trickle all the way down to the remainder of the style world.

Fashion lovers were shocked at Gucci’s freaky catwalk show that saw models strut their stuff carrying fake heads. Whereas the fashion things were spectacular, two of Gucci’s models stole the show by taking to the runway carrying 3D printed replicas of their own heads.

Unsurprisingly, the 3D printed heads have caused quite a stir on social media and have even been the inspiration for a number of funny memes.

Now lets Star Trek Online captains 3D print their starships:

March will be a great month for spaceship captains within the Star Trek online universe. Partnering with cloud 3D printing business Mixed Dimensions, Star Trek online will, come March, enable gamers to 3D print their own personal starships from the sport as 12-inch organic resin models. The new in-game feature will direct gamers to Mixed Dimension’s GamePrint internet site, which will offer different purchase choices.

Nearly all the five hundred playable starships will be created 3D printable, whereas personal customizations like ship names, colors, and defend skins will all be incorporated into the print. On the cheaper finish, gamers can elect a single-color or pre-primed model, however, people who need their ship rendered within the most magnificent detail will select a luxury hand-painted possibility.

3D printed Custom Prosthetic Arm:

In the UK, a father has 3D printed a custom prosthesis arm for his 10-year-old son, who was born without a left hand, while across the pond in Missouri, a teenager has 3D printed a custom prosthetic arm for his veteran amputee father. Teenager Robbie Freis used his 3D printing skills to fabricate a new arm for his father, a veteran who was injured in a 2003 RPG attack in Iraq. It was a touching attempt, though Freis did have one ulterior motive for his project: getting his dad back on the video games!

It’s a beautiful picture of 3D printing in 2018.

3D printing does great things in a lot of areas, but one of the most directly beneficial uses for the technology is prosthetics. All around the world, there are many organizations who are dramatically cutting the cost of prosthetic limbs for those in need, while individual makers are also designing and 3D printing their own prostheses using homemade designs or models sourced from the internet.

Credits: Thingiverse.com, Google.

]]>

We’ve seen 3D printed cameras before, but they include some prefabricated parts: a hinge, a spring, or more complicated bits like shutters and iris mechanisms. Therefore, if you’re looking to add a camera model for your micro. You can choose from different makes and models. Camera cases 3D print is useful. But before going forward, just take a look at its important elements:

We’ve seen 3D printed cameras before, but they include some prefabricated parts: a hinge, a spring, or more complicated bits like shutters and iris mechanisms. Therefore, if you’re looking to add a camera model for your micro. You can choose from different makes and models. Camera cases 3D print is useful. But before going forward, just take a look at its important elements:

- Film cartridge

- Path of film across the frame

- Film take-up spools on the other side of the frame

- A set of gears to rotate the spools at the right speed

- A shutter

- An aperture plane

- A lens

- A door to access the film

- A lightproof box to hold it all

If you’ve got the camera … however, you wish a case or mount to place it! If you have got access to a 3D printer, things suddenly get a lot of fascinating. Hence, you’ll use them with the ever standard print software system and monitor your prints. Therefore, use it for your fancy DIY monitor.

Here, it is the best 3D printed Raspberry Pi camera case.

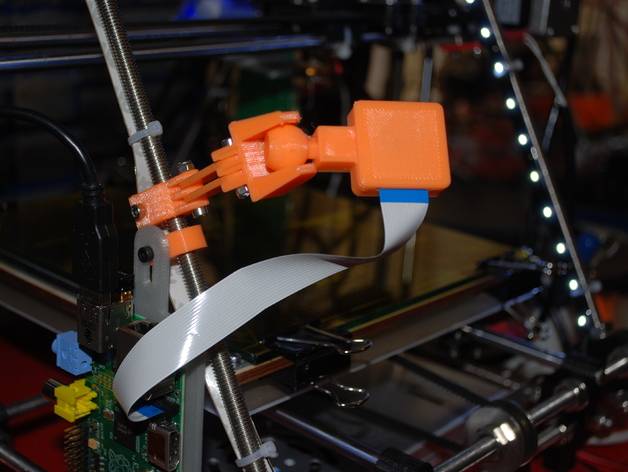

Raspberry Pi Camera Mount with Ball Joint for Reprap

This is specially designed to mount on a Prusa i2, RepRap pro or similar. The mount on a Raspberry Pi camera with a ball joint is for extra flexibility.

Who made it? 3dKarma

Download: Thingiverse

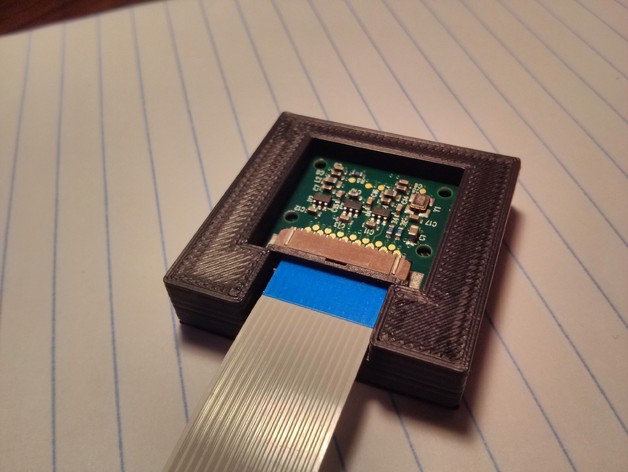

Enclosure for Raspberry Pi Camera V2 with a hole on the bottom to accept a tripod thread

This is the raspberry pi camera module fitted inside a 3d printed enclosure. Therefore, mounted to a 3d printed tripod. This simple design is easy to 3d print and takes a few minutes to put together.

You can use a Swivel-Head Adapter to adjust the position of the camera with a free range of motion. Hence, it locks in place with a side screw. You’ll need a few machine screws and other camera bits to assemble this project along with the 3D printed parts and raspberry pi camera module.

Who made it? Adafruit

Download: Thingiverse

Tom’s Raspberry Pi Zero Camera Mount for Zebra Case V1

This is a remix version of Tom’s Raspberry Pi Camera Mount V4 + (optional) LED Mount V. Therefore, as we know, things are getting smaller and smaller. So for this, we need Pi Camera mount for Rasberry Pi Zero (W) in Zebra Case.

Who made it? Tomulinek

Download: Thingiverse

The Mountster: a Raspberry Pi Camera Mount

The Mountster is a monster mount for the Raspberry Pi Camera. Hence, you can screw the cam to print using the two holes on the side of the lens. Also, there is an opening for the focus light.

Who made it? Jeromemaurey

Download: Thingiverse

Raspberry Pi Camera to Microscope Adapter

These two pieces fit together in order to adopt a Raspberry Pi Camera to a Celestron microscope. The first piece (rectangular one) fits the Raspberry Pi camera, while the second piece (cylindric tube) fits the microscope. Hence, two pieces snap together.

Who made it? Luisibanez

Download: Thingiverse

Need a 3d printer so that you can start printing all your favorite designs? I hope the article of Raspberry Pi camera cases 3D print is helpful for you all. Why not take a look at our Store for some sweet deals?

Credits: thingiverse.com

]]>

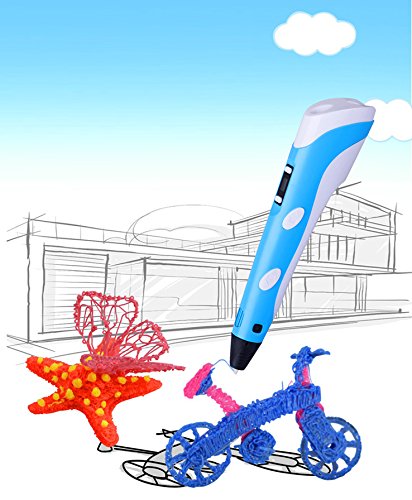

3D pen vs 3D printers

But if you are thinking that there is some connection between 3D printers and 3D pens. Because both are used for printing then my friend you are wrong. There’s no relation or connection between 3D printers and 3D pens. They both are designed for different functions. The 3D pen uses plastic to draw an object or a structure; solely you hold the extruder in your hand instead of let motors, and a laptop does the work.

To draw the 3D object using your pen. All you need to do is fill your pen with the plastic filament that comes with the kit. The heating technology utilized in the pen can mechanically heat the plastic. Eventually, the plastic turns from solid to the liquified state and at this stage you’ll just about draw something. That you just need to together with your 3D pen. And you’ll draw on surfaces like walls, furniture, and plastic.

Note: To help you narrow down your options, we’ve listed out the most popular 3D pens that people are using this year.

Scribbler 3D Printing Pen V3 – A Teenager’s Best (Pen) Friend

As we know technology is beyond our imagination and the Scribbler 3D Pen is the perfect example of it. Basically, it is a handy tool that is created especially for teenagers. The 3D drawing pen comes in beautiful colors which include yellow, blue, green, white, red, and purple. This pen is extremely lightweight and easy to use.

As a parent, you would surely want a bright future for your child. For young teenagers, this is an engaging and exciting experience, one that they will cherish and appreciate. You can expose your child to 3D printing from an early age, opening the window to their curiosity for new tools and technologies. So, which will come in a helpful way when they move towards higher education.

Glyby Intelligent 3D Printing Pen – Best Seller Pen

For those who are new to the art of 3D printing, getting a good start is challenging. So you have to start with a good 3D printing pen. You need to work with the best 3D pen that flows without a single hitch. So you can concentrate on the craft. The Glyby Intelligent 3D Printing Pen is the #1 bestseller 3D printing pen. It comes with a feature that automatically switches the device to standby mode after five minutes of inactivity. Every button on the pen functions as it is supposed to do and it is very easy to manage.

3 Doodler 2.0 – A Version that Gives You a New Vision

Launched in 2013, 3Doodler 2.0 has been a favorite choice among many 3D pen lovers. It’s the newest and improved version of 3Doodler, which is the world’s first 3D printing pen.

In terms of looks, the pen looks more stylish than its parent version. It’s sophisticated and more futuristic. The 3Doodler 2.0 is 75% smaller than the original, making it similar in size to a marker pen. It is also lighter at just 50 grams or half the weight of the original and should come with a stronger and better looking anodized aluminum case instead of the plastic one used by the original. These things should make the 3Doodler 2.0 3D printing pen easier and more convenient to use as well as more attractive looking. Talking about extras, this one comes with 50 plastic filaments out of which 25 are PLA plastic filaments and remaining are ABS filaments. But it is not just the look and feels that have been improved; the functionality also promises nice improvements such as lower power usage, optimized and quieter cooling, better speed and performance and more. Above all, if you are someone that is more conscious about the looks, then you’ll love this version.

Investing in the 3D printer may be a very pricey deal and a lot of therefore if you’re obtaining it for brief-term use. Apart from the investment to induce one, alternative expenses like renewal, replacement, and maintenance are reaching to add up to lots of cash going out of your pocket. This is where 3D printer pens can come as a good alternative and help you enjoy the advantages of a really affordable valuation.

Draw Your Future Bright with 3D Printing Pens!!!

If you want it simply confined to one thing like your kids’ college projects, presentation, or an exhibition, the 3D printer pens would be a sensible choice than 3D printers.

]]>Yes! it’s possible to create almost anything via 3D printing may it be 3D printed cars, 3d printed machines, 3d printed accessories,3D printed shoes etc. 3D Printed houses are getting much popular as a machine printing a whole house without any manpower is quite mesmerizing, you just need to have the design ready, a proper filament and a worthy 3D Printer.

Apis Cor

This 3D printed house is going viral on the internet the reason being it was printed in less than 24 hours. A house made in less than a day is hard to imagine but 3D Printing has made this possible.A Russian company, Apis Cotr has made this happen with a mobile printer and a mobile 3D printer and automatic mix and supply unit, developed specifically by Apis Cor.The total construction cost of the house $10,134.

The important components of the house including walls, partitions, and building envelope were created with a concrete mixture.

The remaining fixtures like furnishing and windows were later added on, and a shiny coat of paint was added to the exterior of the house.

Ideal for the off-grid living, Ukrainian company is making this house as a stand-alone and energy efficient concept.

The basic motto behind this house is it can be built without external structures like water tanks, plumbing and can exist autonomously and sustainably with zero carbon emission. This house is pre-constructed in a factory and then can be deployed so quickly that anyone can move places within a day of buying the house.

A number of features make the PassivDom sustainable like the walls are 3D printed, the windows are made with an insular material for air and heat management and it runs totally on solar energy. As the need for compact and more compact houses is growing so is the demand for PassivDom kind of houses. They have off-grid optional connections for important elements like water and energy. The housing units are being sold for between €29,900 and €64,900.

Earthquake-Proof Modular Homes

A 500 square meter villa by the Chinese architect group Zhuoda Group , constructed in the factory and then ship it to the construction site.It could be built completely in 15 days. The company guarantees the house to withstand a level 9 Richter scale and can survive to 150 years.

“Infinite” Landscape House

Have you heard about Mobius strip Infinite loop? If not, then you can see this house which is exactly constructed in the same manner as the Mobius strip by a Dutch architect Janjaap Ruijssenaars. He has created a huge D-shaped printer in order to build what he has named the “Landscape House”.

It has a 1000 square meter of space and it can be used for exhibitions.This innovative printer is created by Enrico Dini and can print up to almost a six-meter-by-six-meter square. The way it works is like a normal 3D printer, as it builds up fine layers just 5-10mm thick with the help of a computer. It creates an illusion that you can walk through the house until the end of time.

Upstate New York House

D-Shape Enterprises and NYC architect Adam Kushner present a 2400 square feet house with a totally classy touch.The Italian 3D Printing pioneer Enrico Dini, the founder of D-Shape Enterprises has made these house, built in Upstate and taken over by Kushner and his wife.

The property includes a jacuzzi, car garage and a swimming pool. Their printing process begins by collecting dust, sand, and gravel. These raw materials are mixed with magnesium base so that to create a printable construction material. The printer is capable of making building blocks of 6-by-6 meter cube and the collaborative effort is still being continued to complete the project.

Freedom space

Designed by WATG Urban, the Curve Appeal home won the Freeform Home Design Challenge in 2016 – and it’s slated to break ground this year after a research and development phase.

The undulating slopes and space-age design so the name Curve appeal. The home allows efficient technology binding with the surroundings and nature.

The global design competition challenges the architects to come up with new innovative ideas and theories for the real world living.So there is a lot going on in the 3D Printing age and we need to stay updated wit the trend.

It is like a dream come true to stay in one of these 3D Printed houses. So get ready for exploring a whole new world of architecture with 3D Printing industry. You can get your own 3d printer at Geeetech.You can check more about the 3D Printed houses here.

Credits: all3dp.com,archdaily.com,passivdom.com.

]]>The biggest environmental issue is to tackle plastic waste. Plastic has been accumulated on our earth since it was discovered and there is no way out to get rid of it, an alarming sign of pollution now. But it can be recycled and reused, so the better way out of this pollution problem is 3D Printing. You can mix the same Geeetech filament material, like all PLA small pieces of each roll to melt them all together with the same heat. Make them directly into one artwork. Be careful with the melting process. furthermore, it is eco-friendly to produce 3D printers from E-Waste.

We cannot stop utilizing plastic but surely make the most of it by recycling it. Read the stories below to know how to efficiently use the wasted plastic while 3D Printing:

Precious Plastic Project

As the name suggests Precious Plastic is the global community of environment lovers who look forward to ending plastic pollution. Here anyone can share their collaborative techniques and ideas. Already many people are working towards reusing old plastics and making creative useful products.

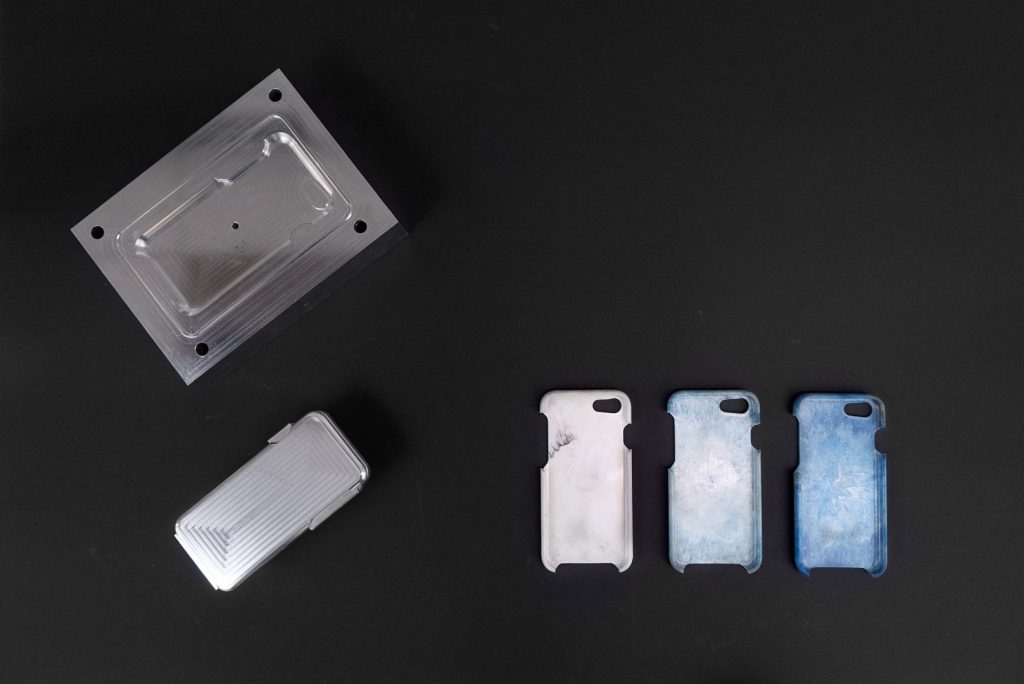

Currently, the team is turning otherwise unrecyclable plastic into functional smartphone cases. Anything from old plastic bottles to takeaway cup tops is being combined to create new iPhone cases. Precious Plastic has created a manufacturing ecosystem to help people to turn plastic waste into valuable products.

We previously covered the project during the initial launch of its open-source production platform. The company also provides a toolkit and machinery including a plastic waste shredder, an extrusion machine to create 3D printing filaments from recycled plastics, an injection molder, as well as a compressor to help process the molds. To check the efficiency of these tools they are creating iPhone covers as the first project from recycled plastic.

Reform the campus

UC Berkeley is a leader in 3D printing having students all over the campus printing their favorite things and exploring which also creates a lot of plastic waste. Almost over 600 pounds of trash is generated all over. The students Nicole Panditi, and Scott Silva have a solution.

They’re creating a campuswide system that takes used 3D printer plastic, grinds it up, melts it down, and produces a new spool of plastic that can be used again in the campus’s 3D printers.

Even though there have been a few endeavors to reuse 3D printer plastic on campus and some labs purchase reused fiber, this would be the first run through Berkeley to have a framework to reuse all the 3D plastic waste on campus, something Panditi says will be fundamental as 3D printing turns out to be increasingly well known.

From Plastic Bottles

Three engineering physics students at the University of British Columbia in Canada have developed the ProtoCycler, a gadget that can crush a wide range of waste plastic into an excellent clean spool of plastic fiber that can be utilized as a filament of a 3D printer.

We’re talking anything – plastic jugs, 3D-printing shorts, takeaway nourishment compartments. If your children forget their LEGOs one too often for you to tread on with your uncovered feet… toss them in as well. It works simply like a juicer, which you can find in the video.

Sustainability is what we all are striving for. We can surely lend help to keep the earth pollution-free by whatever means we can. Even if it’s a small thing it matters a lot. Plastic cannot be eradicated but is better used, so making the most of it is in our hands. Not only plastic can be the filament material, but do you know other innovative materials for 3D printing?

Start with a small change and see how the world changes. A push towards 3D Printing and a better world starts here at Geeetech. Join us to make the world a better place to live in.

]]>Essentially, a 3D printing service or company will print your design for you and deliver it right to your doorstep.

All you need to do is upload your model design, STL files, scans or even physical items that you wish to be 3D printed. Apart from this, there are a variety of models available that you can choose from. Alternatively, if you’re looking to sell your designs then you can consider listing your services as well.

We’ve compiled a list of some of our favorite 3D printing services that you absolutely must check out-

1. Shapeways

Technologies: SLS, SLA, Binder Jet Steel, Wax casting, Material Jetting

Materials: Plastic, Metal, Ceramics, Sandstone, Wax

One of the most popular 3d printing services, Shapeways is perfect for both 3d printing enthusiasts as well as newbies. You can either upload your STL files and custom designs or opt for their professionally designed items and customize them to your liking.

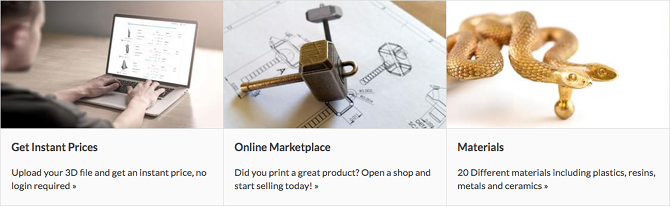

2. i.materialise

Technologies: FDM, SLS, SLA, Casting, CeramicJet, Colorjet, DMLS, Indirect Metal Printing, Polyjet

Materials: Plastic, Metal, Ceramic, Wood, Resin, Sandstone

Similar to Shapeways, i.materialise lets you upload your designs and have them printed out for you. For designers, they can either sell their 3d print designs via the gallery on the i.materalise online store or embed them into their website.

3. 3D Hubs

Technologies: FDM, SLA, SLS, Jetting, Metal Sintering, Paper, PolyJetting, CFF, Wax Casting

Materials: Plastic, Metal, Paper, Resin, Stone, Wax

Rather than 3d printing your object for you, 3D Hubs lets you connect with professionals who own a 3d printer and will print your design. It’s even more convenient as you can find someone living in your area itself who offers 3d printing services, upload your STL files and instantly connect with them to get an estimate.

The company makes sure all transactions between the “hubs” and customers are performed properly. You can find these 3D Hubs all over the world mainly in Europe and the US but also in Australia, Asia, Africa, Russia, and South-America.

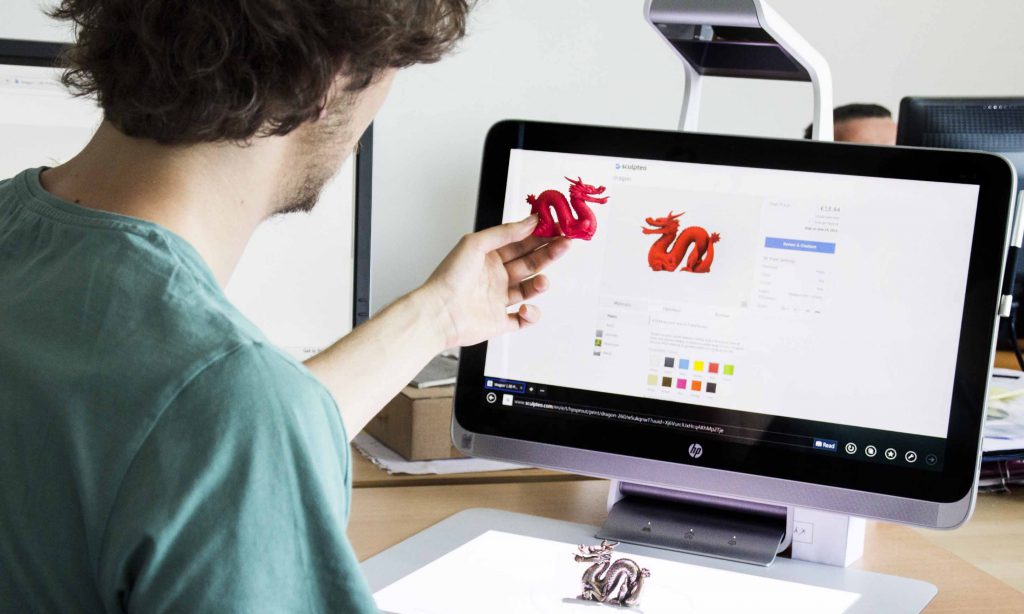

4. Sculpteo

Technologies: FDM, SLS, SLA, DMLS, Casting, CLIP, ColorJet

Materials: Plastic, Metal, Ceramic, Resin, Full-color, Wax

Sculpteo offers a large variety of materials and 3D printing technologies to choose from. From art pieces to jewelry and interior decorations, you can find something that you love and even take it one step further and customize it. Like the other online sites, Sculpteo too offers hobbyists and professionals to open up an online storefront and sell where they can sell their designs.

When asked about his views on 3D printing, the founder of Sculpteo, Eric Carreel says “Soon, instead of buying things that are made in large quantities at factories, we will buy objects made in quantities of just one, specifically for us”. And if you take a look at Sculpteo, you’ll feel the same!

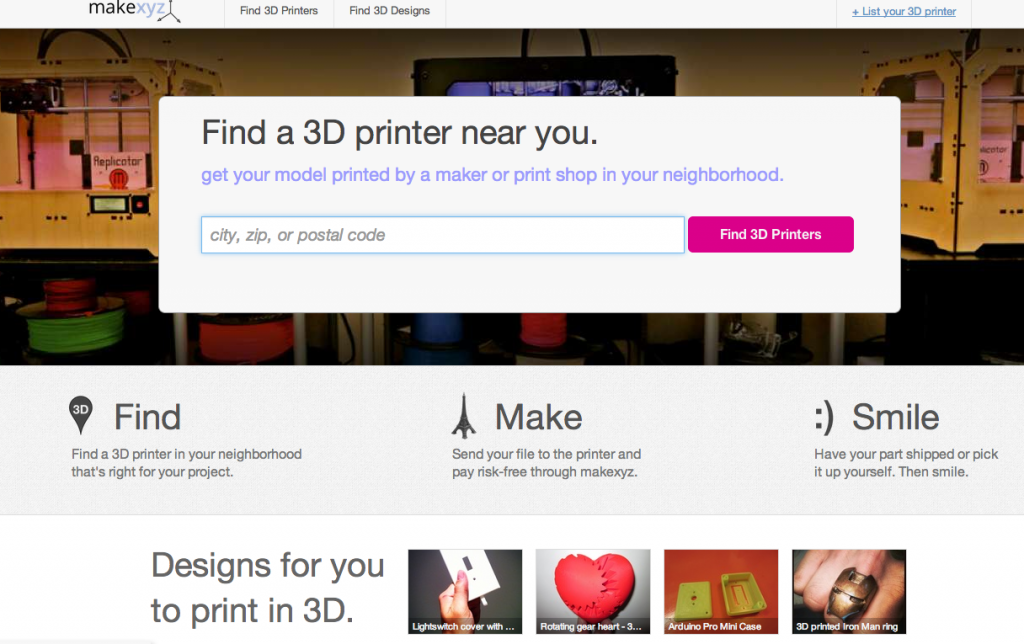

5. MakeXYZ

Technologies: FDM, SLS, SLA, Material Jetting

Materials: Plastic, Resin, Nylon

What sets MakeXYZ apart from other online services is that it offers you a handy little perk. You can either upload your files and have them printed or you can choose to allow an experienced Makexyz print manager handle the process for you. For newbies especially, this tool gives you a very smooth experience.

Apart from this, you can upload your files in a variety of formats like stl, obj, zip, step, stp, iges, igs, 3ds and wrl. The site also includes a “Find 3D Printers” list that includes the printer’s name, location, and his/her 3D print capabilities.

3D printing services are also a great way to test out 3d printed objects before buying your own 3d printer. And if you love the experience and can’t wait to buy your own then take a look at our Store.

Credits: imaterialise.com, makexyz.com, sculpteo.com, 3dhubs.com, shapeways.com

]]>It’s hard to believe that something as common as a toilet which is a necessity in our daily lives, is not so common in the lives of millions living in India. Many that do not have access to toilets even end up using public areas. Toilet scarcity is a national problem in India affecting more than half of India’s population and even resulting in deaths due to unhygienic conditions.

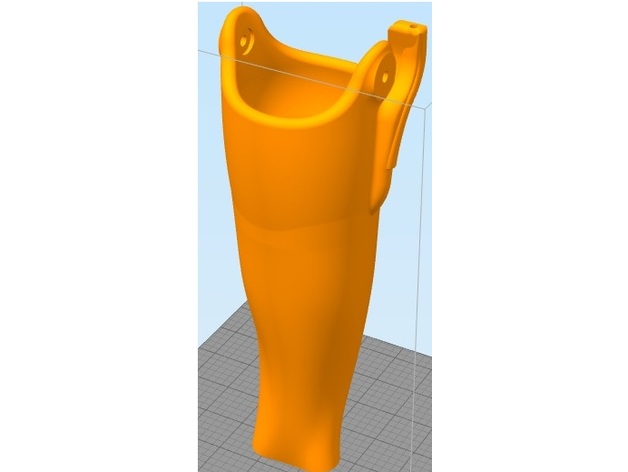

Luckily, Hamilton Labs, based in Singapore, is developing 3D printable toilets to help improve poor sanitary conditions in India. Using Hamilton’s robotic HamilBot Mark 1 3D printer, India is about to see a brand new change that could potentially save many lives and drastically improve the quality of life.

Scarcity of toilets in India

Being the second most populated country the world, India’s poor sanitation, and hygiene problems are definitely distressing. About 524 million people do not have access to local toilets, defecate in the open which further leads to diseases and deaths as the cycle goes on.

In order to change the current situation, the government has undertaken a pledge to make India an open defecation free country by 2019. But to make this dream a reality, construction of over 100 million toilets across the nation need to be funded. And though, around 60 million new toilets have been built, 40 million more are still needed.

The main reason why there aren’t sufficient toilets is that these regions are severely lacking in trained craftsmen who can construct the required toilets as well as low funding. Since Hamilton’s 3D printed toilets are much more affordable, India could see a big change.

Hamilton Labs lends a helping hand

Having signed an agreement with India’s Center for Rural Information and Action (CRIA) Hamilton plans to use one of its robotic 3D printing systems to build 3D printed concrete toilets in Bihar, Northern and Eastern India. Known as the HamilBot Mark 1, this robotic 3D printer will be used to build toilets that are comfortable, quick to print and beautiful to look at.

Working with Singapore’s National Additive Manufacturing Innovation Cluster (NAMIC), a collaborative 3D printing scheme organized by Nanyang Technological University (NTU), the National University of Singapore (NUS), and the Singapore University of Technology and Design (SUTD), Singapore’s Hamilton Labs could be about to contribute massively to India’s sanitary project.

The 3D Printed Toilets

If you’re wondering what these 3D printed toilets will be made from- it’s definitely not your average PLA and ABS. A special cement made from recycled fly ash, which is a product of coal combustion will be used. This fly ash is abundantly available in countries that use coal-fired power plants like India.

Hamilton’s HamilBot Mark 1 3D printer which is powered by a robotic arm, is a large-scale 3D printer. Take a look at the printer in action:

HamilBot Mark 1 is capable of working 24/7 with theoretically minimal manual input. That cuts down not only cost but also the timing to construct these toilets, were it to be done by manual labour! The project to build these toilets in India is expected to start soon, with the robotic cement 3D printer expected to arrive at its destination later this month!

Its awe-inspiring to see such advancements in the 3D printing industry adnd we’re so ecited to see what’s in store for the future. Could there be a day where every single thing around is 3dprinted?? Well we’ll have to wait and see to find out!

Credits: 3ders.org, youtube.com

]]>