The United States Army Research Laboratory and Texas A&M University have developed a family of synthetic materials that are capable of self-healing.

The polymers vary in texture, from ultra-soft to extremely rigid. They can be 3D printed, are recyclable, and stick to each other in air and underwater.

Such materials are expected to be used in fields ranging from prosthetic limbs to flexible aerospace components.

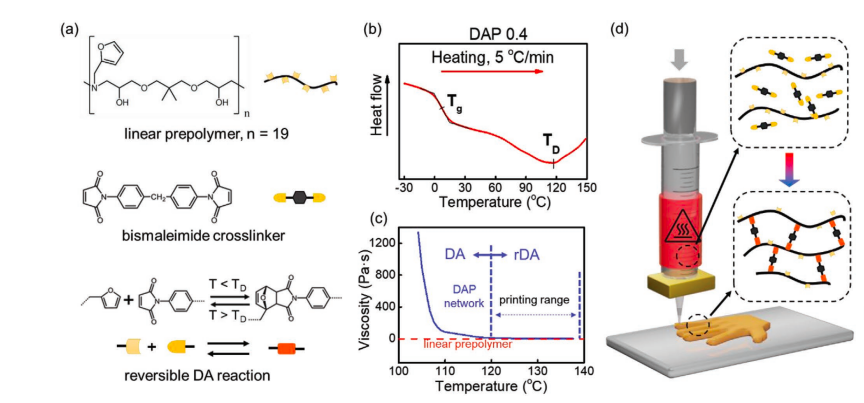

The resin consists of long strings of repeating molecular motifs, while the elastomeric polymers exhibit lightly crosslinked chains providing a rubbery feature to the material. Different amounts of BMI were “inlaid” onto the polymers and connected to two cross-linked molecules of furan and maleimide by a thermal reversible DA reaction. It has been found that changing the number of cross-linked molecules adjusts the stiffness of the material, potentially raising it to 1,000 times the level of a standard photosensitive polymer.

Researchers also noted that the temperatures when the crosslinkers dissociate are nearly same for different stiffness levels. This property is useful for 3D printing.

In the evaluation experiment, the team found that changes at 80ppm and 176ppm indicated that the process slowed down when the crosslinking agent was used up. The tensile strength of 3D-printed DAP is also higher than that of molded samples, at 0.5-0.7mpa, indicating that the material has the ability to fill gaps in traditionally printed parts.

The team further tested its DAP network, matching different cross-linking densities with different mechanical properties to create parts with mechanical mismatch interfaces. A pressure test shows that the component has a higher strength than parts manufactured using conventional FDM polymer materials.

“Right now, we can easily achieve around 80% self-healing at room temperature, but we would like to reach 100%. Also, we want to make our materials responsive to other stimuli other than temperature, like light.” says Frank Gardea, corresponding author on the study and research engineer at the United States Army Research Laboratory

The team concluded that the new materials have the potential to be applied to parts in terms of strength and elasticity, but the amount of BMI needs to be adjusted to create the parts. Their new 3D-printed materials, though still in need of further tweaking, will one day be used to make a range of diverse objects that are 100% self-healing.

Source: army-technology; i3dpworld