The U.S. Army plans to use 3D printing to print warhead components which couldn’t only save the army money, but also expand its capacity of creating more effective weapons, according to the latest issue of Army Technology.

The army is investing in regenerative medicine and 3D bioprinting aiming to print skin cells on the patient using a 3D bio-printer to help injured soldiers recover from the wounds of war. But for the Army, the more important task is to print weapons.

3D printers can produce metallic shapes that are impossible or far more expensive to produce when using machine tools. And the boundless potential of the shapes made possible by additive manufacturing inspires design engineers in the Army.

Warhead designers attempt to create blast effects that meet specific criteria, explained James Zunino, a researcher at the Armament Research, Engineering, and Design Center. They may want blast fragments of specific sizes to radiate in specific directions such that their blasts can most effectively destroy desired targets.

“Warheads could be designed to meet specific mission requirements whether it is to improve safety to meet an Insensitive Munitions requirement, or it could have tailorable effects, better control, and be scalable to achieve desired lethality,” James Zunino, a researcher at the Armament Research, Engineering, and Design Center wrote to Motherboard.

The limits on what can be produced using machine tools limit warhead shapes. By lifting limitations through the expanded capabilities that come with additive manufacturing, space is used more efficiently.

“Once you get into detonation physics you open up a whole new universe,” Zunino said.

“The real value you get is you can get more safety, lethality or operational capability from the same space,” Zunino said.

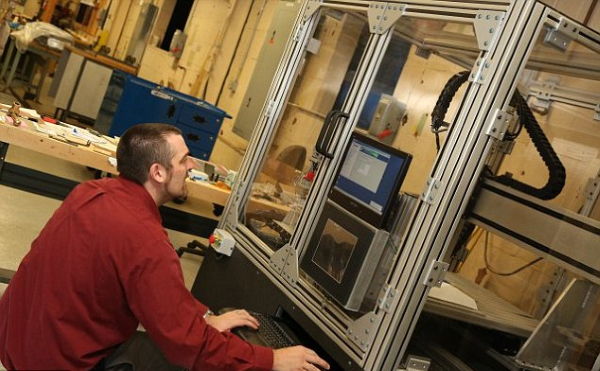

In addition, 3D printing also helps the army saving money on getting parts or tools delivered to a forward-deployed soldier. If you add up all the cost, including the transportation costs, fuel, security, it will be much cheaper to just print them out.

“3D printing also allows for integrating components together to add capabilities at reduced total life cycle costs,” Zunino explained. “It is expected that 3D printing will reduce life-cycle costs of certain items and make munitions more affordable in the long run through implementation of design for manufacturability, and capitalizing on the add capabilities that 3D printing and additive manufacturing can bring to munitions and warheads.”

Eventually, the army wants to print the whole thing in one print job. “Maybe someday an entire warhead or rocket could be produced as the technology further matures,” Zunino wrote.

(Posted in 3D printing Applications)