Do you sometimes feel it is a challenge to figure out which 3D printer filament will work best for the design you want to print, or are you just looking to brush up on your knowledge of ABS 3D printing techniques? In any case, we will go over everything involved with the process of using ABS plastic filament, including the print settings and which applications and designs are best suited for this material. Enjoy!

What Is ABS Filament?

Before we get to deep into the specifics and settings, let us first make sure we are on the same page regarding ABS 3D printer filament and what it actually is. In short, ABS stands for Acrylonitrile Butadiene Styrene, which is a thermoplastic material that many of us already know well, since it is among other things what the world famous LEGO blocks are made of.

Therefore, it is a safe material that has been tested over many decades. It provides great strength properties that lends itself well to many applications, and it is also highly resistant to heat, making it a solid contender for prints that should not deform due to heat. Furthermore, you can drill and sand the heat resistant 3D printer filament as well, and even use acetone for a clear and smooth finish. Geeetech filament uses enhanced versions of the basic ABS material, known as ABS+ filament which is even better for 3D printing with the improved overall properties.

ABS Print Settings

In order to help you make the most of your 3D filament, and answer common questions, such as what temperature does ABS print at, we have made a quick overview in the table below. Use this as a starting point for your ABS 3D printing projects, but feel free to modify the values if you believe it will work better. These settings have been extensively tested with our very own Geeetech filament ABS+, which allows for optimal 3D printing with ABS plastic projects.

| Setting | Recommended Values |

| Nozzle Temperature | 220-250°C |

| Hot Bed Temperature | 90-110°C (Can be turned off, but low temp increases adhesion) |

| Printing Speed | 20-150mm/s (Depends on the individual design) |

| Adhesion & Bed Surface | Use blue tape, PEI board, or BuildTak for better adhesion. A thin layer of glue or ABS glue stick can also help. |

| Cooling Fan | No fan required. Using a fan may cause warping or cracking. |

| Support Structure | Tree support or grid support |

What Support Material Is Required for ABS?

Since ABS is an extremely strong and tough material, sometimes it can be difficult to remove the self-supports when printing those with ABS as well. Instead, some users use specialized support materials like PVA, HIPS or Breakaway Supports in combination with the ABS plastic filament, in order to get the best of both worlds. See the table below for inspiration.

| Support Material | Pros | Cons |

| ABS | Simple to use | Can be hard to remove |

| PVA | Water-soluble, easy removal | Requires a dual extruder |

| HIPS | Soluble in limonene, great for dual extrusion | Needs limonene for dissolution |

| Breakaway | Easy to remove | May leave marks, requires post-processing |

Post-processing

One of the major advantages of using ABS filament for your 3D prints, is the ABS temperature resistance properties, that allows for many different post-processing techniques without ruining the look or compromising the structure of your newly printed models.

| Post-Processing Method | Description | Effect/Benefit |

| Sanding | Uses sandpaper or sanding sponges to smooth rough surfaces. | Reduces layer lines, prepares for painting or coating. |

| Spraying | Applies primer, paint, or clear coat using a spray can or airbrush. | Enhances appearance, provides color and protection. |

| Hot Water Treatment | Briefly dips or rinses the print in hot water to relieve internal stresses. | Reduces warping and minor surface imperfections. |

| Coating & Sealing | Uses epoxy resin, polyurethane, or acrylic coatings to add durability. | Strengthens and waterproofs prints, improves surface quality. |

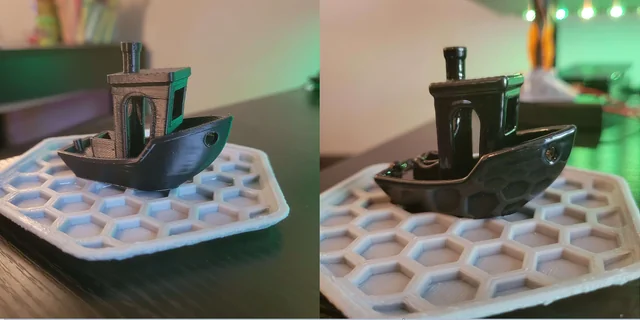

| Acetone Vapor Smoothing | Exposes ABS to acetone vapors in a controlled chamber. | Creates a glossy, smooth finish by dissolving outer layers. |

Applications

In order to provide you with some inspiration for what is possible using ABS 3D printing techniques, we have gathered some very different ideas below, to help you get started with your next project or just inspire you for your own designs. All of these are made by 3D printing with ABS plastic.

Car Interior Panel

BMW provides MINI owners with personalized interior customization services.Owners can choose different patterns and colors of interior panels according to their personal preferences, which are manufactured and loaded into the car through rapid 3D printing.

ABS 1/4 inch Barbed Connector

This filament is also great for DIY connectors for your garden hose or other similar types of equipment and tools. Due to the strength and heat resistance, it can be used for many years outside without issue.

Wheel for your office chair

Have you ever had to throw out your favorite chair because one of the wheels broke? Or perhaps you just want to save some money and not purchase a replacement wheel? Then ABS can help you out as well! Look online for different designs that are universally adaptable to any chair.

Phone stand

ABS is also a great option for a phone stand, as the durable and solid material will not bend or flex, making it the perfect companion for late night binge-watching, or perhaps as a holder for your video shoots.

Conclusion

ABS is one of the best 3D printer filament types currently available to consumers, as it offers many different advantages and allows for durable, heat-resistant, and versatile prints. As long as you use the correct 3D printer filament settings, and optionally use our ABS+ filament, then you will get perfect results every time!