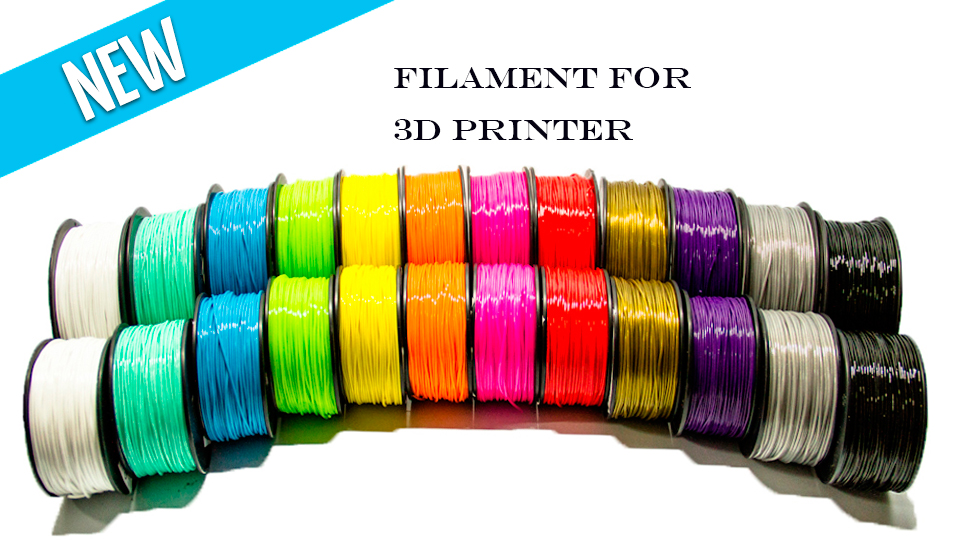

PLA (Polylactic Acid) is one of the two most commonly used desktop 3D printing materials (with the other being ABS). It is the ‘default’ recommended material for many desktop 3D printers, and with good reason – PLA is useful in a broad range of printing applications and has the virtue of being both odorless and low-warp. PLA is also one of the more eco-friendly 3D printing materials available; it is made from annually renewable resources (corn starch) and requires less energy to process than traditional (petroleum-based) plastics. Outside of 3D printing, PLA is often used in food containers, such as candy wrappers, and biodegradable medical implants, such as sutures. PLA is available in a wide range of colors in both 1.75mm and 3mm (check your printer specs to determine the correct size). For tips and tricks on 3D printing in PLA, check out How To Succeed When Printing In PLA.

ABS (Acrylonitrile Butadiene Styrene) is another commonly used material in desktop 3D printing. Useful for making durable parts that need to withstand higher temperatures. In comparison to PLA, ABS is less ‘brittle.’ It can also be post-processed with acetone to provide a glossy finish. When 3D printing in ABS a heated printing surface is recommended, as ABS will contract when cooled. ABS is available in both 1.75mm and 3mm diameter sizes.

PRO Series PLA is a formulation of PLA intended for producing professional, high-quality, 3D-printed parts. It features a visually distinct finish, with a more vibrant, opaque coloration, than standard PLA. PRO Series PLA is made in the USA and is produced to a more precise specification. It is available in 1.75mm and 3mm.

PRO Series ABS is a formulation of ABS filament intended to help your 3D prints stand out with a beautiful, glossy opaque finish. It is made in the USA and best used when producing high quality, precision prints. As with regular ABS, it will withstand higher temperatures than PLA; it also requires a heated bed for proper printing. PRO Series ABS is available in both 1.75 mm and 3mm diameter sizes.

Soft PLA, also known as ‘flexible’ PLA, is useful for printing rubber-like parts that can bend or flex. It is compatible with almost all desktop 3D printers. Soft PLA is available, as an individual spool or as a sampler pack of each color, in both 1.75mm and 3mm.

LAYWOO-D3 is a wood-like 3D printing material that gives 3D printed objects the look and feel of fiberboard. It also imbues parts with other wood-like attributes, such as the ability to be cut, painted, and sanded. It is also possible to give parts printed in LAYWOO-D3 a simulated alternating light/dark wood-grain appearance by varying the temperature during printing. LAYWOO-D3 is available in 1.75mm or 3mm unspooled rolls.

LAYBRICK is a 3D printing material that gives parts the look and feel of grey stone while retaining the resiliency of plastic, making it ideal for landscape and architectural designs. Anything made with LAYBRICK can be painted and sanded. In the lower range of 165°C to 190°C, the print will come out mostly smooth, whereas with higher temperatures it will begin to have a more pitted, sandstone-like texture. LAYBRICK is available in both 1.75mm and 3 mm unspooled rolls.

Nylon is a versatile 3D printing material that prints as a bright natural to white with a translucent surface and can absorb color added post process with most common, acid-based clothing dyes. Unprinted Nylon is extremely sensitive to moisture, so taking drying measures during storage and immediately before printing is highly recommended for optimal results. Taulman 618 is a 3D-printing specific formulation of Nylon that comes in a variety of sizes and packages, including 1-, 2-, and 3-packs of both 1.75mm and 3mm.

PVA (Polyvinyl Acetate) prints translucent with a slightly yellow tint and is primarily used, in a 3D printing context, as a support material because it is water-soluble meaning that it will dissolve when exposed to water (and so MUST be kept dry prior to use). PVA is most often used on printers with dual extruders, with one extruder printing a primary material (such as ABS or PLA) and the other printing this easily dissolved material to provide support for overhanging features. PVA is available in 1.75mm and 3 mm.

Bendlay is an exciting new filament that is extremely translucent (91% of light passes through) and also is quite flexible. This extremely translucent material will allow you to print nearly clear items, while at the same time being remarkably resilient and elastic. BendLay is a modified Butadiene, which is safe for household and food products. BendLay has a high interlayer adhesion, making it a really wonderful and easy-to-print filament. Compared to ABS it also absorbs far less moisture from the air and thus cuts down on warping significantly. Bendlay is available in 1.75mm and 3mm.

TPE is a flexible 3D printing material that feels and acts much like flexible rubber. TPE can be used to make parts that can bend or must flex to fit their environment – stoppers, belts, springs, phone cases, and more. This extremely flexible material will allow you to create prints that will have the properties of a soft rubber, making it even more flexible and elastic than our Soft PLA filament. TPE is available in 1.75mm and 3mm.

Polycarbonate (PC) Polycarbonate is strong and very resistant to impact – this material is used when making bulletproof glass. Polycarbonate is an extremely tough and durable thermoplastic material that is temperature resistant. This material is malleable while cold and can be bent without cracking. Polycarbonate is available in 1.75mm and 3mm.

Thanks for sharing.

Comments are closed.