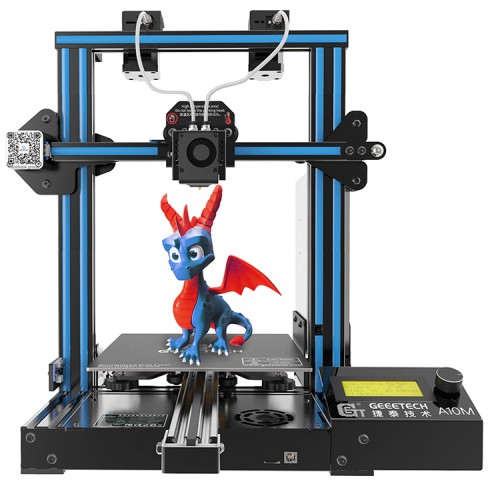

Introducing the New Geeetech A10M and debunking myths around dual extruder 3D printers.

Are you bored with monocolor 3D objects, or tired of having to manually remove the support structures off your 3D prints? If so, the Geeetech A10M might be your go-to printer. It is picked by 3dnatives as the No. 1 dual extruder 3D printer for 2019. In the artical, A10M is dubbed as “a 3D printer for makers”.

Now, 3D printers that come with a dual or triple extrusion setup have been avaiable for a good number of years. On top of that, there are other options in the Geeetech “A” family that allow for multi-color/material 3D printing, such as the A20M/T, A30M/T, which are more advanced than the A10M. With that said, the A10M, aside from being user-friendly, is the most affordable dual extrusion system in the “A” series. Not to mention the fact that the new version features an upgraded mother board, LCD screen and new gantry. It is therefore safe to say the upgraded A10M is one of the most competitive multi-material 3D printer for beginners and the frugal-minded who are looking to enrich their 3D printing experience.

But before we move on, let’s first debunk the following myths around dual extruder 3D printers.

Myth #1 –Dual extruder 3D printers print twice as fast as their single extrusion counterparts.

If you are a novice in 3D printing, you are probably wondering why this is not the case. More often than not, a dual extruder 3D system is faster than a single extrusion setup, but it almost certainly does not double the speed, and definitly not for the reason you may think.

The real reason is that, with a dual extruder printer, you can avoid the lengthy process of swapping out one filament for another.

Having more than one extruder allows you to have different filaments piped in from the very start.Changing filaments, whether for a different colour or material, is labour-intensive.With a dual or multiple extrusion design, you no longer have to pause a print, empty out the extruder, feed in the next filament, and resume the print every time you need a different material or color. This is where the saved time comes from. As a matter of fact, the two extruders share the same print head and can’t move independently.

Myth #2–dual extruder 3D printers are only useful for multi-color objects.

The Geeetech A10M features a 2 in 1 out design. It enables you to print with numerous combinations of colors using the Color Mixer software developed by Geeetech. But its another, more common use is to seperate the filament used for printing your object from the support material, which is often less expensive, of lower grade, and soluble in water, and will eventually be removed.

A single extruder 3D printer is actually capable of printing multi-color objects and support structures. But the whole process is tedious, as pointed out above.

The Geeetech A10M comes half assembled , and is easy to set up. Check out the unboxing video here by Hoffman Engineering on Youtube.

This blog post will be updated when full review video is out. Stay tuned!

A10M on Amazon: https://amzn.to/3gN3l0C