Innovative wood-based materials for 3D printing

As an organic polymer, lignin plays an important role in providing rigid support for plants. It strengthens the cell walls of plants and causes them to turn woody (lignify) – a mechanism that helps plants to protect themselves against wind or pests.

Lignin has traditionally been a waste product from paper manufacture. A number of research groups have previously worked on ways to recycle it, for instance using it to produce carbon fiber, stronger concrete and even to reduce the cost of making batteries.

In reality, however, much of it is still burned to produce bioenergy, as part of the papermaking process,

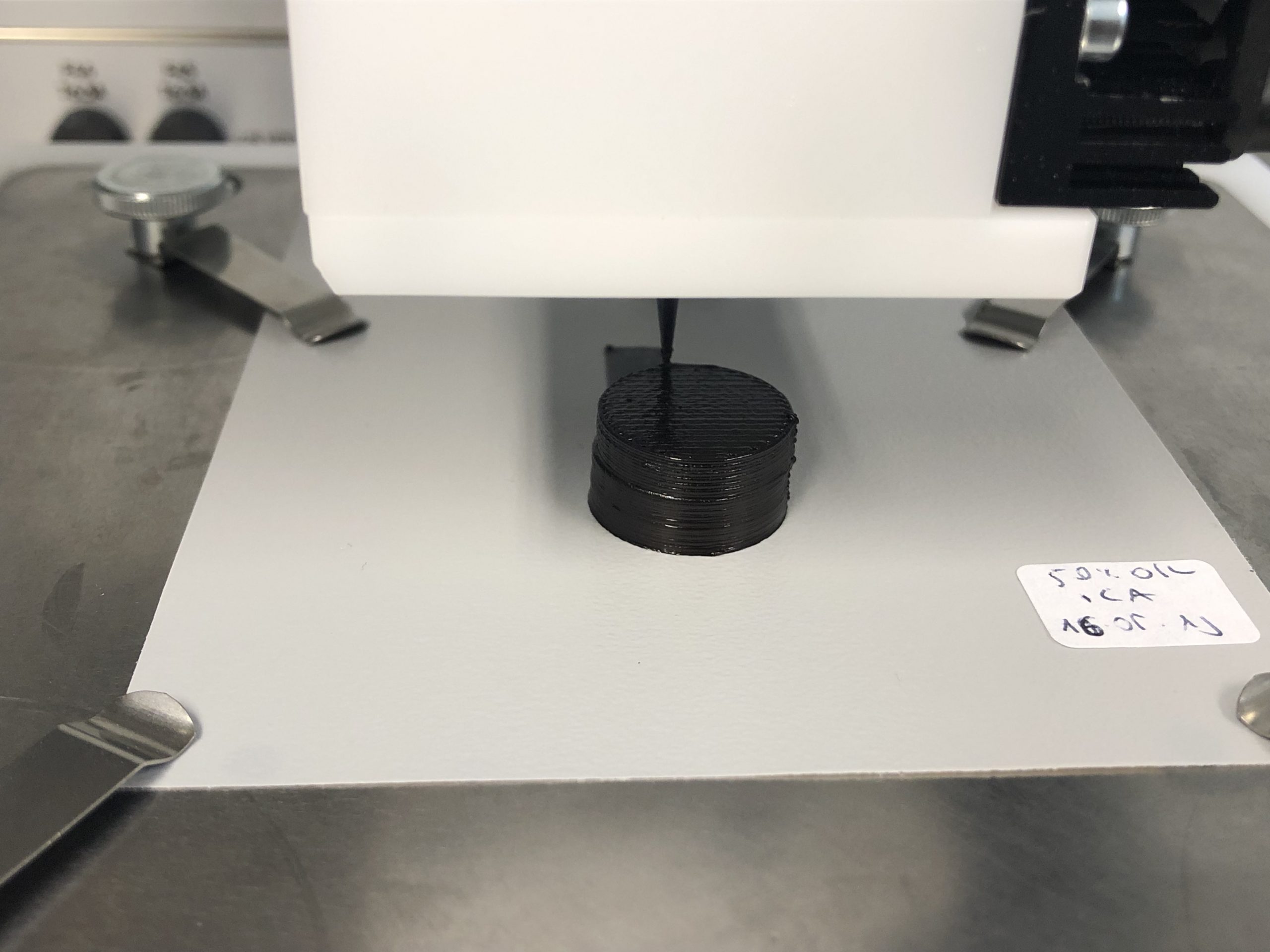

“This is why we’re researching into alternative possibilities for making better use of this raw material in future,” says Marie-Pierre Laborie, a professor at the University of Freiburg,whose team has come up with an innovative way to “reuse” this natural material by transforming it into a biopaste using 3D printing technology. The viscous biopaste is easy to process, solidifies quickly and is suitable for producing complex structures.

In this system, liquid crystals based on cellulose, the main component of plant cell walls, ensure not only the strength but also the good flow properties of the biopaste. The other component, lignin, can ‘stick together’ the microstructure in the process of creating the biosynthetic, as Robert Gleuwitz discovered in his doctoral thesis. Its orientation subsequently determines the characteristics of the biosynthetic: for instance, it can respond more rigidly or more flexibly, depending on the direction from which the force comes.

Further research work are necessary until industrial application is possible. Until now the team has used exceptionally pure lignin which is produced in a pilot biorefinery at the Fraunhofer Center for Chemical-Biotechnological Processes (CBP) in Leuna – whether the waste product from the paper industry can also be directly processed still has to be researched. As Lisa Ebers shows in her doctoral thesis, the characteristics of the biosynthetic varies in many ways, for instance by chemically processing or varying the components: Trials to date have used lignin from beech trees – if it is obtained from other plants it will have slightly different material characteristics such as different liquid crystals, even though they are all based on cellulose. The optimal quantity ratios also differ depending on the planned application. In addition, the researchers will soon be testing an entirely different possible use: the quality of soil can be analyzed with the help of the bio-based material. This takes place by studying the degradability of lignin and cellulose in various types of soil.

The results arose from a research project by the Sustainability Center Freiburg and the Fraunhofer Society. The research and 3D printing trials took place in cooperation with Prof. Dr. Dr. Christian Friedrich and Dr. Gopakumar Sivasankarapillai at the Freiburg Materials Research Center (FMF) of the University of Freiburg and with Dr. Gilberto Siqueira in the Swiss Federal Laboratories for Materials Testing and Research (EMPA) in Dübendorf, Switzerland.