Why These 3D Printing Filaments Are The Best – Part II

This is the continuation of the previous article. 3D Printing requires a passion and little knowledge about the software used. Choosing a 3D Printing filament is a difficult task, you need to do a little bit research about it, like what you are going to print, which type of material can help in printing the design you made more precisely, your budget, do you wanna print the parts differently and then join it or printing it altogether as one print.

Know these different filaments which can help you decide which one to choose :

Ceramic (Clay)

Ceramic 3D printing is rather costly and it requires a special printer which itself transforms the ceramic powder to build the model layer by layer from bottom to top. .Ceramic 3D Printing is gaining popularity due to its versatility, certain advantages and safety of the material. A basic 3D printer for ceramic printing has to be used where the ceramic powder is used as the filament. Ceramic clay is basically food-safe, recyclable, and water-tight, ceramic is a great material to use for cups, plates, statues, or figurines. You also need to use different 3D Printing tools that are developed specially for ceramic 3D Printing. Even if you are a rookie in ceramic printing don’t worry, there are various services that make your experience a better one like Shapeways or iMaterialise.

Wax (Moldlay)

Dominating the wax 3D Printer with conventional material like wax which is lay developed by Kai. Her innovations in the 3D printing material industry us fascinating with all the Laywood and Laybrick being the most popular to consumers and copycats. Moldlay is the new development. Moldlay is designed specifically for the use of creating positives for investment casting molds.

When using this material Wax 3D printing and lost wax casting is used to build your design. The wax printing process is a type of stereolithography that uses a wax-like resin. Support structures are printed along with the model to make sure your model doesn’t fall apart. These support structures are automatically generated and manually removed after the printing process. After support structures are removed and your model is cleaned, the model can be prepared for casting. You can make any metal mould by using Moldlay as your 3D printing material, like gold an silver for jewellery.

This process is mostly called “lost-wax” or “investment” casting, and it works like this:

- Create a wax replica of what you want the final metal product to look like.Just draw out your imagination.

- Dip the mold into the plaster and let it dry.

- Put this wax-plaster object in an oven. At a high enough temperature, the wax will melt away, leaving a negative space within the plaster, in which the metal product can be cast.

You need to keep certain things in mind while printing out with this material as the wax objects are too soft.

PVA (Polyvinyl alcohol)

When you are about to print complex objects a strong material for support is required not only from outside but also from inside where reaching is hard. In such case Enter Polyvinyl Alcohol, a water-soluble support material that dissolves away in a water bath to leave only your perfectly printed part. PVA and PLA area perfect match as they share a very similar printing temperature and are both very easy to print.

Like nylon, PVA is hygroscopic, which means it absorbs water from the air easily. When you first open your roll of PVA filament, stash the desiccant that it came with so you can store it in a sealed container when you aren’t using it. If you happen to forget to store it and the roll sits out for too long, you will notice your PVA hissing and be popping as you print, indicating it absorbed water. All is not lost, simply dry it in the oven for a couple hours to pull all the moisture out and then store in a sealed container.PVA is a great support material when paired with another 3D printer filament in a dual extrusion printer. The advantage of using PVA is that it can be used with ABS, PLA and nylon.

ASA (acrylonitrile styrene acrylate)

ABS also has its flaws, therefore, all the filament manufacturers are always looking for other alternatives. ASA is more resistant to the weather effects. ASA is being primarily used in the automotive industry. ASA is extremely resistant to chemical exposure, heat, and most importantly, changes in shape and colour. It is also strong, durable and easy to print with. Prints made of ABS have a tendency to erode or to yellow if left outdoors. Such is not the case with ASA. For anything from birdhouses to custom garden gnomes, look no further than this 3D printer filament.

ASA can easily crack when the environment is too windy so please do take care of the products you make with it.

PP (Polypropylene)

Polypropylene is used in a wide variety of applications including textiles, ropes, carpets, stationery, packaging, containers (including most plastic living hinges), loudspeakers, automotive components and polymer banknotes.

PP is mostly hard to print with due to the poor layer adhesion and heavy warping. Since many household items are made from PP,it’s too easy to recycle the items to make the 3D printing filament.

Acetal (POM)

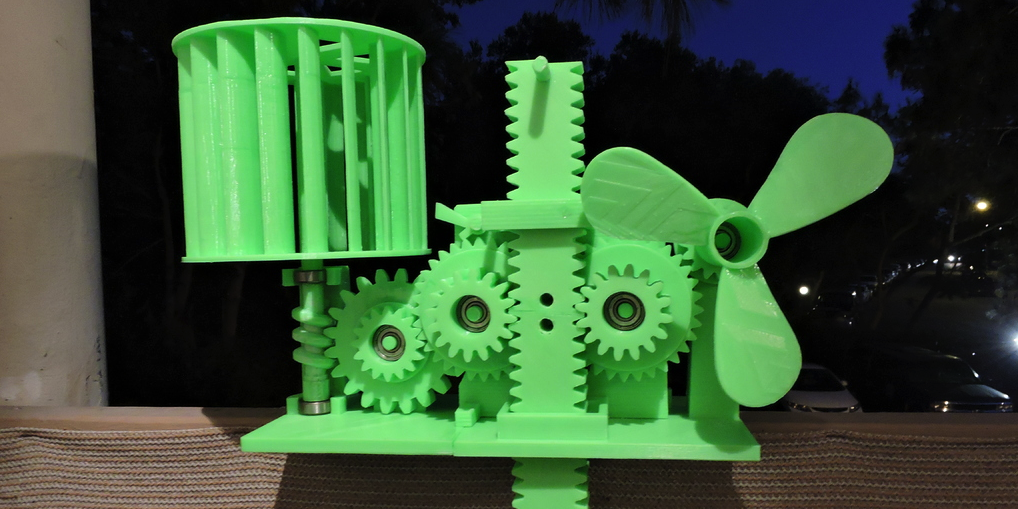

Items with high precision like gears, camera, bearing, focusing mechanisms, and zippers are prepared from POM.Due to its strength, rigidity, resistance to wear, and most importantly, its low coefficient of friction. it is used in engineered objects. As this material is too slippery it can be only used in manufacturing units where there are mass parts to be produced.

Thus Acetal( POM ) is basically an industrial 3D printing material.

Thus all the above filaments are a must and also have their unique uses. You can’t use nylon as a material to print the strongest parts like gears and bearing. That is why you need to know about the 3D printing materials and filaments and then use the knowledge properly while you are 3D printing.

Credits: all3dp.com.