Difference between revisions of "Geeetech Mizar Pro 3D Printer"

(→Introduction) |

(→Introduction) |

||

| Line 77: | Line 77: | ||

'''Packing Dimension''' 512(L)*512(W)*274(H) mm | '''Packing Dimension''' 512(L)*512(W)*274(H) mm | ||

| + | |||

| + | Watch the unboxing video and [https://www.geeetech.com/download.html?version_id=524 user manual] before assembling the printer. | ||

==Product details== | ==Product details== | ||

Revision as of 09:06, 21 June 2023

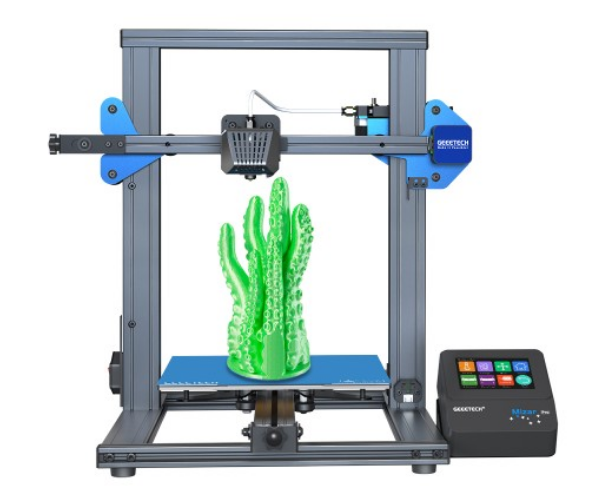

Introduction

Mizar Pro owns dual leveling technology, its printing accuracy is higher and the hot bed has been fixed, so don't worry about the hot bed being deformed or loosened. Its build volume is 220*220*260mm, and the appearance is more concise and beautiful, which can meet most of your printing needs!

Precise Auto leveling GEEETECH Mizar Pro has dual-leveling system, which enables one-button ABL automatic bed leveling technology. It is equipped with a high-precision leveling sensor and no need for external leveling accessories like BL touch.

It also creatively designed manual leveling mode, which is more friendly to beginners, amateurs and specialists.

Stable Magnetic Platform The heat bed adopts a fully fixed design, The hot bed can be used for a long time after leveling once with the leveling sensor, do not need frequently leveling the hot bed;The hot bed printing platform adopts the magnetic suction method. Compared with the ordinary magnetic printing platform, the top component of the Mizar Pro printing platform is made of metal material, it is durable and easy to remove the model.

Super Silent Driver The Mizar Pro motherboard uses a high-performance 32-bit MCU with faster printing speed. TMC2208 silent driver can effectively reduce the noise of stepper motor than Atmega2560, the printing sound doesn't exceed 50 dBs, which will not disturb your and others work, study and rest.

Resume Printing Function This 3d printing machine can detect interruptions of power failure, filament run out or stuck, it will automatically pause and save the printing progress, when you handle the exception, it'll resume the previous printing task, which gives your printing work an extra layer of protection.

Main Specification

Printer Type FDM

Layer Thickness 0.1-0.3 mm

Printing Material PLA,ABS, PETG, Silk PLA, Wood Polymer

Building Platform Volume 220*220*260 mm

Auto-leveling Yes

Break Resuming Yes

Preheat time(110℃) 11 min

Nozzle Diameter 0.4 mm

Positioning Precision X axis: 0.011 mm;Y axis: 0.011 mm;Z axis: 0.0025 mm;

Printing Accuracy ±0.1 mm

Printing Speed 10~150 mm/S; recommend 60~80 mm/s

Display Screen 3.5” Colorful Touch Screen

Operating System Windows, Mac, Linux,

Slicing Software Repetier-Host, EasyPrint Lite, Cura

Supported File Format .gcode

Hotbed Max. Temperature 110 ℃

Extruder Max. Temperature 250 ℃

Environmental Temperature 10-40 ℃

Electrical Parameter

Power Input 115/230 V AC, 50/60 Hz

Power Output DC 24 V-15 A Max, 360 W

Connectivity Interface 1*TF Card, 1*USB cable

Power Supply Unit Certification CE, FCC,ROSH

Mechanical Parameter

Printing Size 220*220*260 mm

Net Weight(kg) 8.9 kg

Gross Weight(kg) 9.6 kg

Printer Whole Size 462(W)*515(L)*445(H) mm

Packing Dimension 512(L)*512(W)*274(H) mm

Watch the unboxing video and user manual before assembling the printer.

Product details

Main Specification

Printer Type FDM

Layer Thickness 0.1-0.3 mm

Printing Material PLA,ABS, PETG, Silk PLA, Wood Polymer

Building Platform Volume 220*220*260 mm

Auto-leveling Yes

Break Resuming Yes

Preheat time(110℃) 11 min

Nozzle Diameter 0.4 mm

Positioning Precision X axis: 0.011 mm;Y axis: 0.011 mm;Z axis: 0.0025 mm;

Printing Accuracy ±0.1 mm

Printing Speed 10~150 mm/S; recommend 60~80 mm/s

Display Screen 3.5” Colorful Touch Screen

Operating System Windows, Mac, Linux,

Slicing Software Repetier-Host, EasyPrint Lite, Cura

Supported File Format .gcode

Hotbed Max. Temperature 110 ℃

Extruder Max. Temperature 250 ℃

Environmental Temperature 10-40 ℃

Electrical Parameter

Power Input 115/230 V AC, 50/60 Hz

Power Output DC 24 V-15 A Max, 360 W

Connectivity Interface 1*TF Card, 1*USB cable

Power Supply Unit Certification CE, FCC,ROSH

Mechanical Parameter

Printing Size 220*220*260 mm

Net Weight(kg) 8.9 kg

Gross Weight(kg) 9.6 kg

Printer Whole Size 462(W)*515(L)*445(H) mm

Packing Dimension 512(L)*512(W)*274(H) mm

Unboxing and proper handling

Watch the unboxing video and user manual before assembling the printer.

Printer Maintenance

Turn the printer on but the screen does not work

Warning: Never install or unplug anything on a printer while it’s being powered!

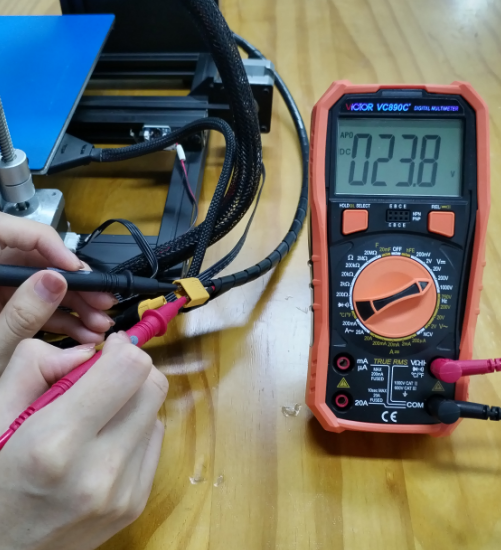

(a)Please check if the power supply is working normally. The red indicator on the switch should be light. Please measure the output voltage, which should be around 24 Volts.

(b)Check the fuse in the little black box, it should be complete without burns. Also check if the power supply connector is burn out or connected tightly.

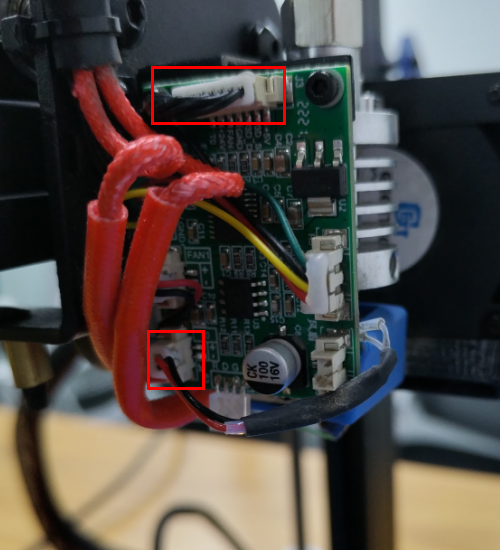

(c)Please check if the control board is working normally. There’re one green LED and one red LED working as the picture shown below. Measure the input voltage of the control board, it should be around 24 Volts.

(d)Make sure the screen is connected properly.

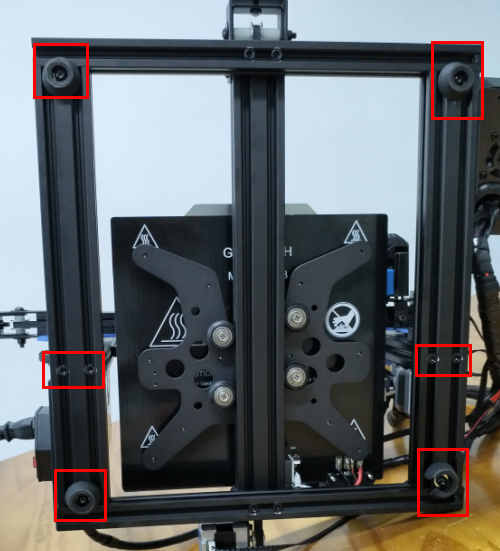

The printer is unstable

Make sure you put the printer on a stable platform, then check if the gantry kit is tightened. Make sure the four rubber mats are all tightened.

Clean hotend

Preheat the nozzle to 220 Celsius from LCD menu.

Use a cleaner rod (1.5 mm diameter, 100 mm length) to push it in and out several times, making the clog out. Do not use excessive force.

Mintemp error

The Mintemp error in 3D printers is a design feature within your firmware for safety in regard to temperature. When below a set temperature, the heater will be switched off due to possibly having a broken thermistor wire. It can be observed a negative the temperature on the LCD screen.

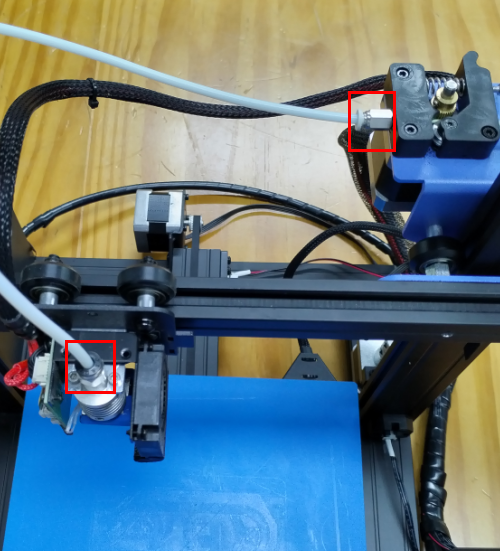

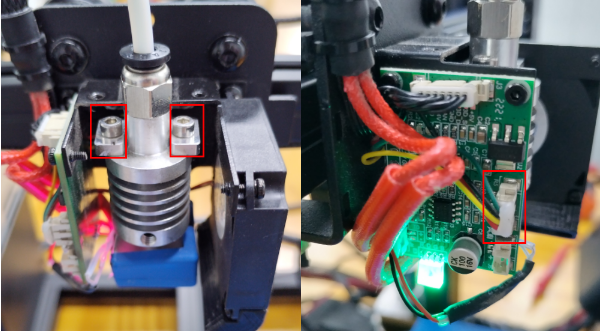

Check if the hot end connector and thermistor are connected properly as the pictures below. Check the hotend cables and thermistor, make sure they’re not broken or burn out.

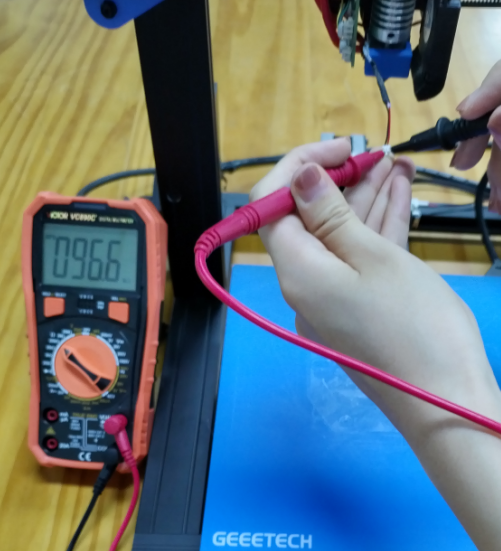

You can test the thermistor by a multimeter. If it fails to read the resistance, then the wire is broken. At room temperature, it should be 80 kΩ - 125 kΩ.

Or apply heat to the thermistor with a heater, blow-dryer or other heating device.

The resistance should decline steadily in seconds if it works. If not, replace it.

Another common reason behind getting the MINTEMP error is from being in a cold environment, especially in winter months. Your 3D printer is designed to have a minimum temperature that it can operate in as a safety feature.

The extruder keeps making a noise

(a)Decrease the print speed. If the print speed is too fast, the extruder will push the filament too quickly. Filament may not have enough time to melt and even clog in the nozzle. A clogged nozzle will then exert pressure back on the extruder, resulting in clicking. For PLA, our recommended print speed is 60mm/s.

(b)Increase the print temperature. If the temperature is too low, it will not melt the filament properly. This can also clog the nozzle. As the extruder is no longer able to push the filament ahead, it starts “slipping”.

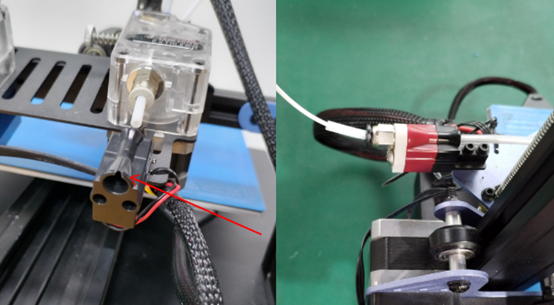

(c)Check the pneumatic fittings. A loose coupling could therefore allow molten filament to leak into a gap between the tube and the nozzle. This will restrict the flow of the filament, causing the extruder keep clicking.

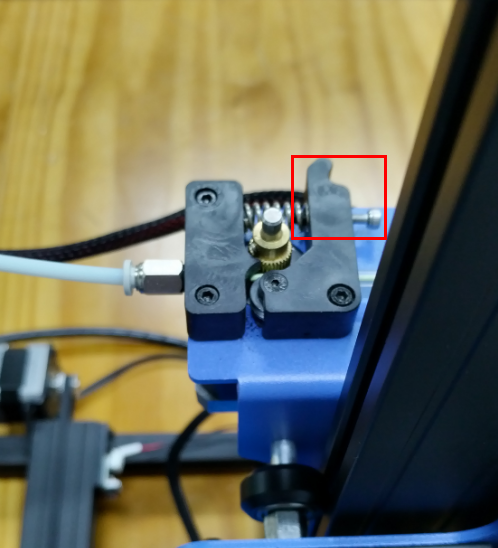

(d)A low-tension extruder arm bar. If spring tension is too low, the extruder gear will not properly grip the filament. This leads to filament grinding.

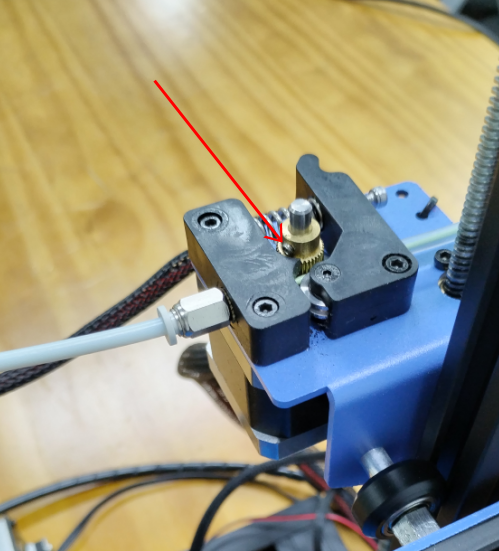

(e)Check if the grub screw on the extruder gear. If the grub screw is loose, the gears will fail to grab the filament when feeding into the hotend.

Nothing is printing

(a)Nozzle is too close to the hotbed Even though the extruder is working but no filament is depositing on the hotbed, Check if the nozzle is too close to the hotbed. Adjust the Z-offset value slightly will help.

(b)Print temperature is too low Some filament needs more higher temperature, manually feed the filament, if it can not be extruded, please try increase the print temperature.

(c)The extruder is not working Check if the grub screw on the extruder gear. If the grub screw is loose, the gear will fail to grab the filament when feeding into the hotend. Also check if the extruder motor is connected properly.

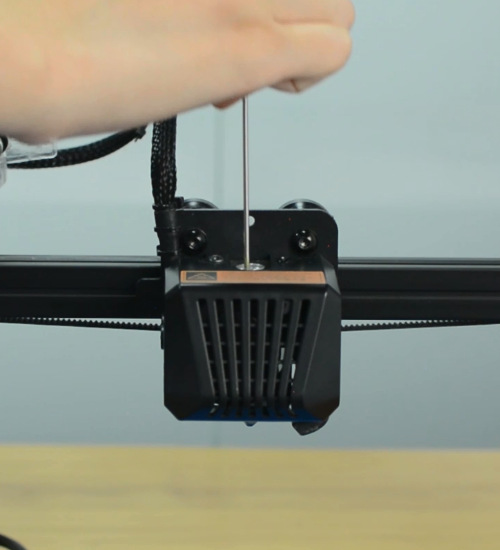

Automatic leveling failed

(a)Nozzle calibration failed You should use a scraper against the nozzle and gently push up to make the nozzle “feel” the pressure. If this still fails, check if the strain gauge in the hotend is connected properly, and ensure the cables are not broken.

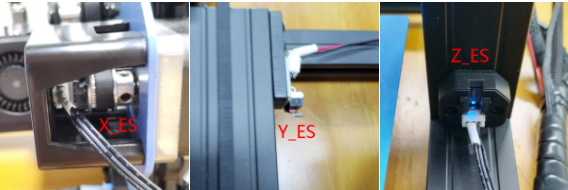

(b)Homing failed Check the X, Y and Z axes end stops, make sure they’re all connected properly. Note the photoelectric end stops on the Y and Z axes, which normally have a blue signal light.

(c)The first layer is messy Please clean the hotbed before printing, this will help to get a good adhesion. We recommend a thicker first layer, 0.3 mm is good. If these’re not helpful, please try to adjust the Z-offset. What’s more, you can try adjust the hotbed temperature, for example, the Geeetech wood PLA needs a lower temperature but PETG needs higher.

Spring steel sheet problem

The spring steel sheet is flexible and easy for part removal. But keep in mind that prints are easy to remove after the plate cools down. Don’t try to forcefully remove the object when the sheet is still hot. We do not suggest you use the adhesive on the sheet, because the adhesive is difficult to clean up and may have an opposite effect.

If there’re leftover residue on the sheet, preheat the hotbed to 80 degrees to make the plastic soft. Then use the wet cloth wiping the plate and gently scrap the residue off.

A dirty bed will cause poor first layer adhesion. You need to remove the dirt, leftover residue or oil from the bed surface. Isopropyl alcohol (IPA) 90%+ will help to degrease the platform.

Filament sensor

The filament sensor will be worn out after long time use. We’ve uploaded a filament guide on our website to fix this.

If there’s error on the screen prompts like “Change Filament” even filament has been uploaded, maybe the sensor is broken. You can test it by a multimeter.

Remember load a small piece of filament through the sensor before test. By touching each of the measurement leads of the multimeter to the two pins of the sensor, a signal (beep or 0 value on the multimeter screen) will indicate that the component is intact and therefore, should work.

Firmware

Download the latest firmware in our website

How to update:

1.Put "bin” file and "assets” folder in TF card root directory, insert TF card into the printer.

2.Turn on the printer, the screen will display the firmware upgrade progress bar.

3.After the progress is complete, the printer starts to upgrade UI.

4.Update is complete.

Notice:

1.After the upgrade, delete the bin file and assets folder in the TF card to prevent repeated upgrades.

2.Level the hotbed after the upgrade is complete.