Trouble Shooting: How to Reduce Stringing

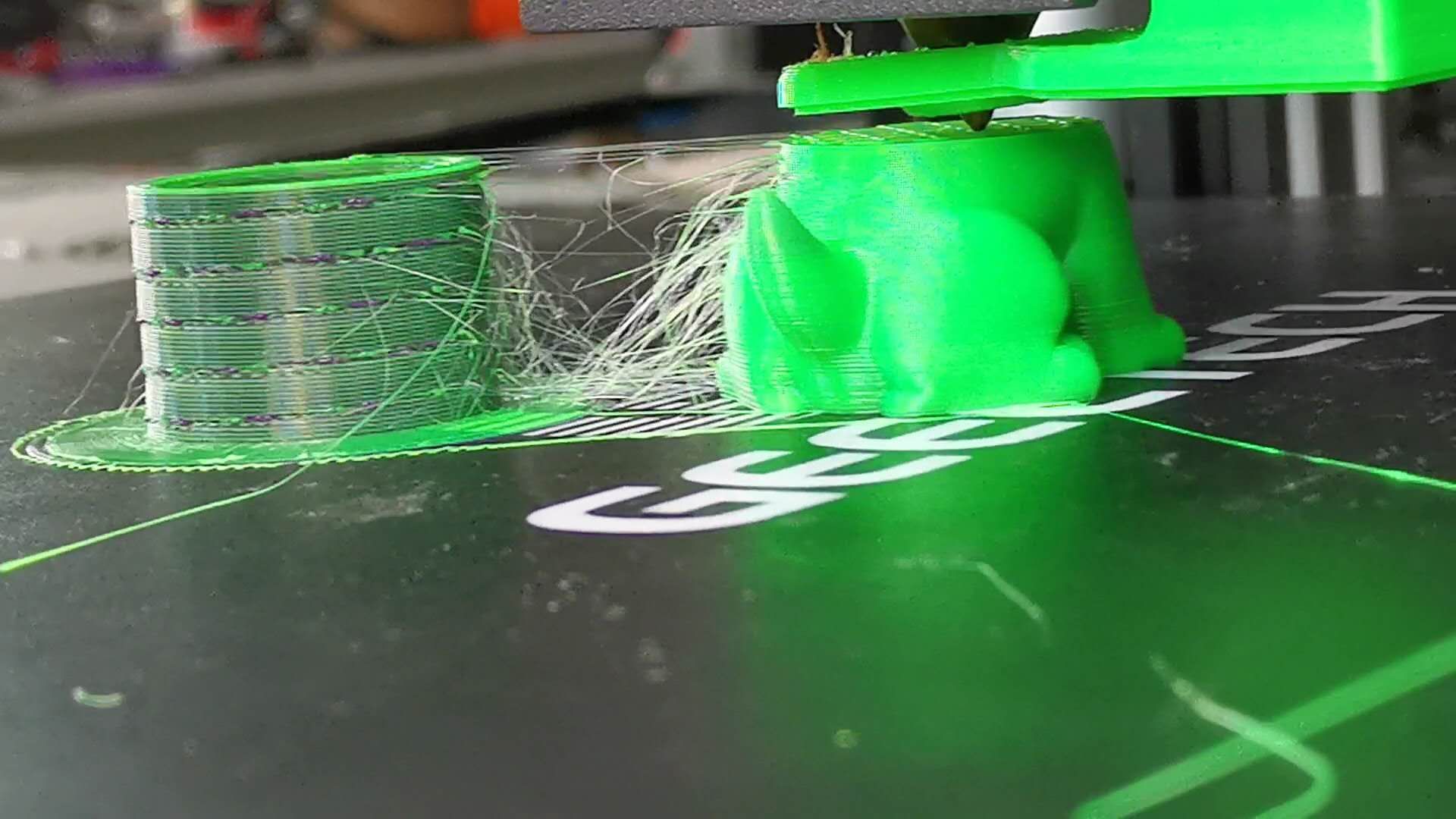

In FDM 3D printing, sometimes the nozzle may deposit unwanted plastic on the printed part where it is not supposed to while the extruder is traveling to a new point; the plastic then cools and sticks to the object, making it look hairy and unsightly.

3D printing stringing can be a common problem especially if you are a newbie or when dealing with a new machine or material. But luckily, it is a problem that is fairly easy to solve. Let’s look at some causes and the corresponding solutions:

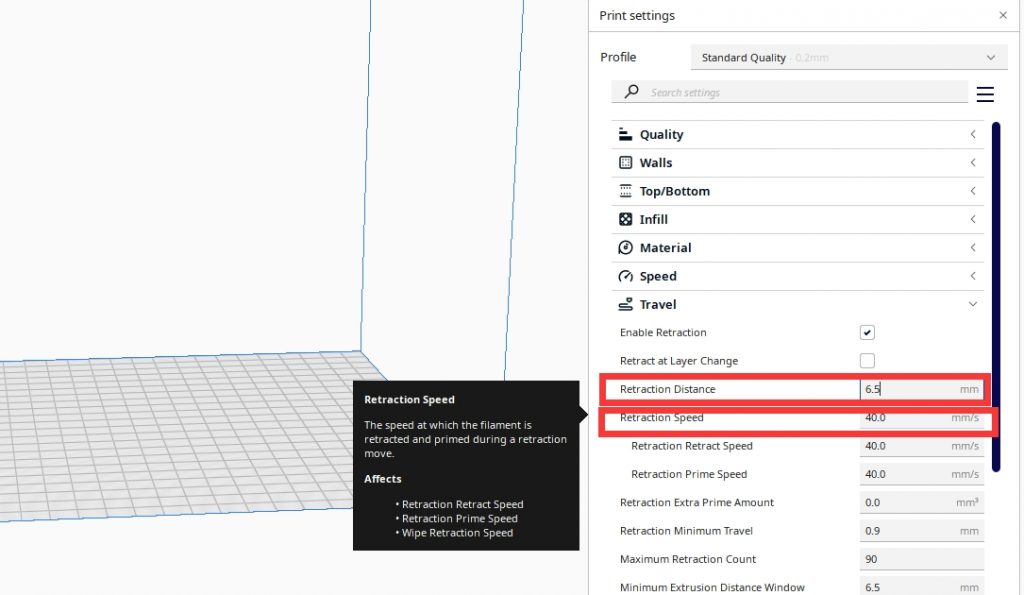

Retraction distance

Retraction distance is the most important retraction setting as it determines how much consumables is pulled back from the 3D printer nozzle. Generally speaking, the further your nozzle retracts, the less likely oozing is to happen. But if the distance is set too high, the plastic may not be able to to reach the hot end and may cause under extrusion. In general, Bowden extruders require a higher retraction distance than direct drive extruders.The optimal value falls in somewhere between 4-7mm(most likely to be 6mm) for most Bowden extruders and 0.5-2.0mm for most direct drive extruders. Some trial and error is probably going to be required to get the retraction distance right.

Retraction speed.

Retraction speed determines how fast the material is retracted from the nozzle. Generally, a quicker retraction will reduce the chances of leaking. But again, it could also be problematic: first, it may cause the plastic to separate from the melted filament inside the nozzle; second, the fast movement of the drive gear could grind parts of your filament away. A sweet spot is usually found somewhere between 25-40mm/s. Again, you will need to experiment to get the optimal value.

Temperature

If stringing persists after you have tweaked around the retraction settings, go on to check the extruder temperature. As the temperature goes up, the plastic inside the nozzle becomes more liquefied and less viscous, and therefore, more likely to drip out of the nozzle. On the other hand, if the temperature is too low, the filament may not be properly heated and melted,creating problems with extrusion. To fix excessive stringing and avoid issues with extrusion, start out by lowering the temperature by 5-10 degrees to see if the print quality improves.

Temperature setting for filaments:

- PLA 185°C – 215°C, hot bed 25°C – 60°C

- Silk PLA 200-230°C, hot bed 40-60°C

- ABS 230-240°C, hot bed 100-110°C

- PETG 220-240°C, hot bed 80-90°C

- TPU 200-230℃, hot bed 50-60℃

Travel distance and speed

Another possible solution to stringing is to reduce the distance between points/locations the extruder travels. As we already know, stringing occurs while the extruder is moving to the next point. Therefore, the reduced travel distance will slash the chances of leaking. By the same token, increasing the movement speed of the extruder can also prevent stringing from happening.

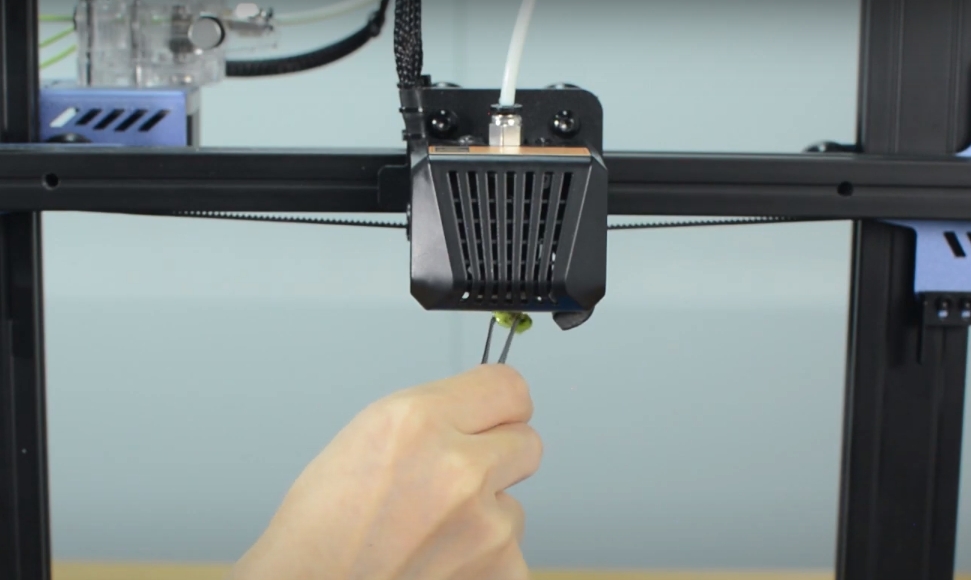

Maintenance

To avoid stringing, you are also suggested to do the following :

1. clean your nozzle. Necessary tools for cleaning nozzle: tweezers, wrench, cleaner rod, needle and allen key. Firstly you need to preheat nozzle and use tweezers to remove extra filament from nozzle. Then you need to unload the filament and pull out the PTFE tube from hotend. Next, use a cleaner rod to push in and out nozzle for several times to clean it thoroughly with proper strength.

2. keep your filament clean and dry. We recommend you to use vacuum bag or dryer box to stock your filaments. If you keep it expose to some extent humid air and dust for a long time then it will certainly affect heating process and more likely to break during printing process.

Reminder: performing a routine maintenance on your 3D printer always helps with your print quality.