Recycling 3D filament- Waste Plastic

3D Printing is becoming more sensitive to plastic pollution that is created while printing the objects. To overcome this thing we need to do the recycling of 3D filament from waste plastic and failed 3D prints.

The biggest environmental issue. That comes along with 3D Printing is the leftover plastic filament or spool after printing your 3D object.

Throwing away the filament in the trash is the only option you are left with. Therefore, there are broken pieces of it and joining them is a costly process. Hence, there comes a filament fuser or joiner which many enthusiasts have already experimented with making. The below video explains how with the help of easy tools you can join the filaments.

There are many methods to recycle the filament and use it the next time. But the method shown in this article is more interesting and leads you to better 3D objects.

Plastic Smoothie Project

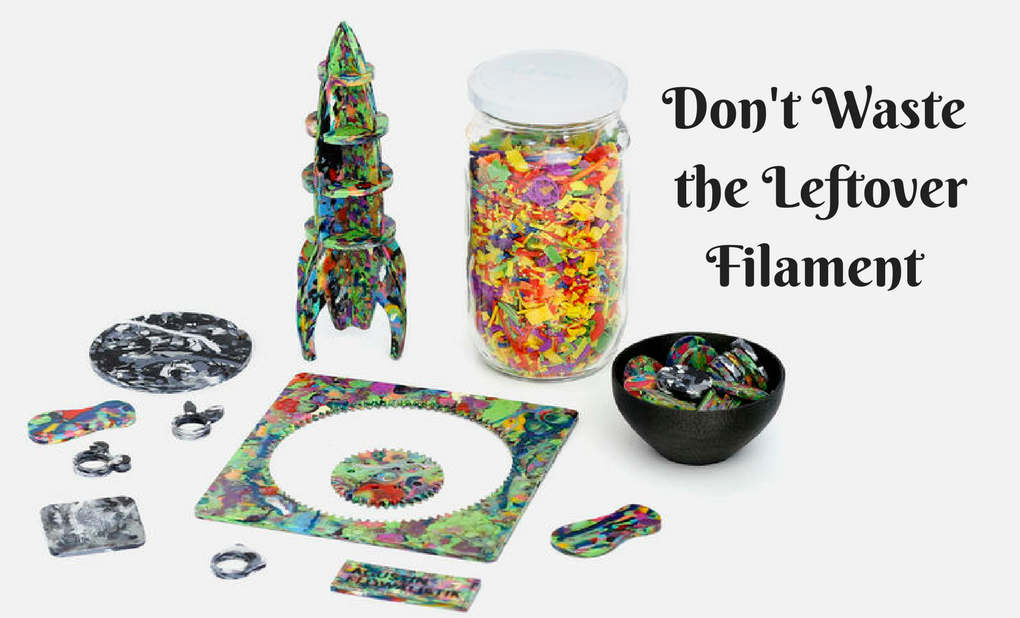

Designer Agustin Flowalistik shows us how to perform the recycling of 3D printer filament waste by creating a Plastic Smoothie, which can 0be used with a laser cutter to create vibrant objects.

Agustin Flowalistik came up with an easy and cheap way to recycle failed designs and leftover filaments by making a concoct of a Plastic Smoothie. He uses the kitchen appliances and laser cutting technology. Therefore, you can create new objects with an endless array of colors. After collecting all the leftover filament and making it into a finely shredded plastic scrap, melt the colorful mess of plastic in an oven. With this freshly-baked sheet of recycled PLA, you can get creative. Also, using a laser cutter and a bit of vibrant imagination.

We give a brief overview of the “Plastic Smoothie” project below so you can get what the project is about. He shared it on Instructables and was developed with the help of non-profit TecnoLab La Rueca Asociacion. Therefore, to increase the quality of life and well-being of disadvantaged communities. You can know more about how to effectively use plastic by controlling pollution here- Worry Not!! You Can Now Reuse Waste Plastic For Your 3D Prints.

Philosophy of the project

Affordable: Electrical appliances are used for most of the projects as it is cheaper to use

Accessible: the machines used should be easily available in online stores.

Open: It’s an open-source project and anyone can be a part of it.

What do you need to do to overcome waste plastic/failed 3D prints?

The first thing that you need is an abundance of PLA filament scraps and failed prints. Also, access to a laser cutter that you will find on Fablab or local maker space. Therefore, if you want to know more about laser printing read here 3D Laser Printing is different from what you think.

There are other supplies needed for starting the plastic smoothie project, this is the checklist:

- Wood panels (40 x 30 x 0.3cm)

- Laser cutter (Flowalistik uses the Epilog Mini 18 40W)

- Blender (recommended 1250 Watts or above)

- Mini Oven (with oven tray)

- Parchment paper

Flowalistik shares some tips to make this project affordable, like using an old blender. Therefore, if you have any as if you start using it to shred plastic you won’t use it for making juice. Before using failed prints make sure to break them before blending them. You won’t want your blender to get damaged. He uses PLA for the project as ABS contains impurities.

Putting it all Together- Recycled 3D filament

The first step is gathering and blending your PLA filament. As a result, you can take the opportunity to decide the colors and textures you want to create. Once the recycled plastic is shredded up, take an over. Flowalistik uses oven paper on the base of the tray, bending the corners to avoid any molten plastic from spilling oven tray and start baking.

Finally, after experimenting the maker found that the best results by melting the small plastic bits at 190-200 C for 20 – 25 minutes. Once the plastic straps are melted, quickly remove them and flatten out on the wooden panels. Perform the pressing procedure quickly as the melted plastic cools down. Finally, keep the oven paper on the plastic and add as much weight as you can onto the wood panels, and you’ll have a perfect sheet of recycled PLA.

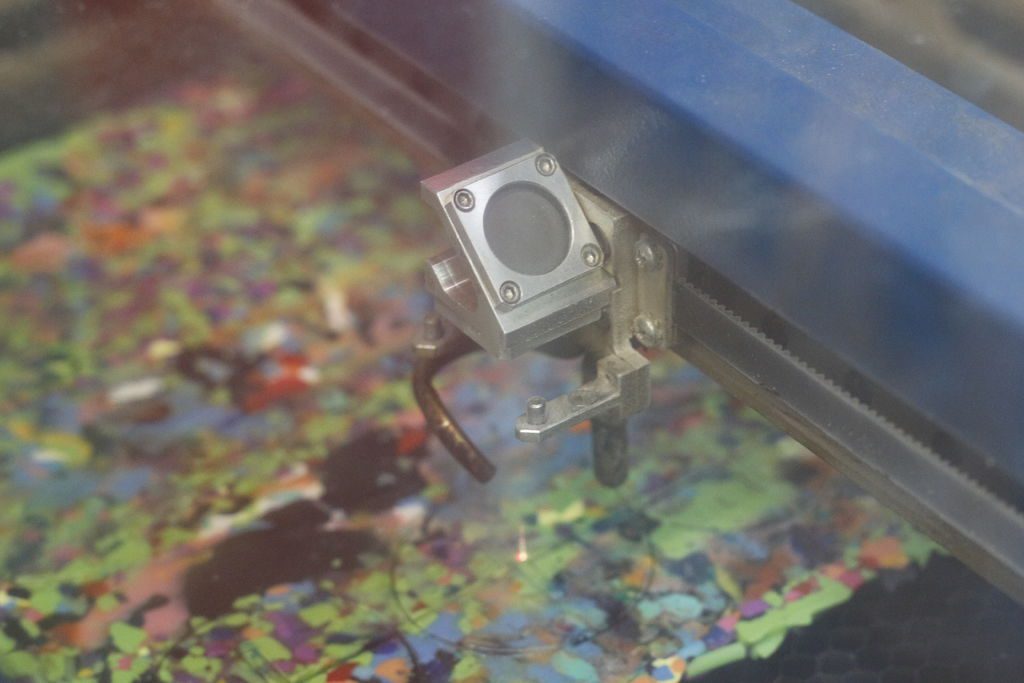

Finally, Flowalistik uses an Epilog Laser Mini 18 40W laser cutter to cut the 3mm plastic panels. You can use the same settings as you would for a 3mm sheet of acrylic. The designer adds that he had to increase the power of the laser in order to make the engraving more apparent.

Therefore, you can learn more about the Plastic Smoothie project and the laser cutting process on Flowalistik’s Instructables post. If you want to continue supporting the designer and his intriguing projects, head on over to his Patreon page.

Plastic pollution is what we are dealing with every day and thus we have to take every possible step to stop it. So do join the “Plastic Smoothie” project and get rid of all the plastic extras and failed prints.

Geeetech enlightens you on such projects which will help you save the environment. This is how you overcome the waste plastic by this useful recycling 3D filament process.

Credits: instructables.com,all3dp.com