DIY: 3D Print your own Bluetooth Speaker

If you have access to a 3D printer, a bit of maker prowess, and a love for sound, you can build your own 3D Printed Bluetooth Speaker it will be mini and handy.

Create your ultimate 3D Printed speaker box

Coder and tinker Yasthil Bhagwandeen shares a new Instructables project. On how to build your very own 3D Printed Mini Bluetooth Speakers, now that is really cool. Therefore, 3D Printing technology is discovering new ways to make things simpler and productive. So even an audio gear is not an exception.

With companies like print+ and V-Moda using 3D printing to offer a modification to consumers. The technology could soon become a valuable part of the audiophile’s sonic experience.

Yasthil Bhagwandeen takes a DIY approach with his new project, showing how to print your own mini Bluetooth speakers. The coder and Tinker show the full process of the project. Right from trials, failures designs to the finished final successful project.

What will you need?

3D Printed mini blue tooth speakers need a handful of components and tools.

COMPONENTS

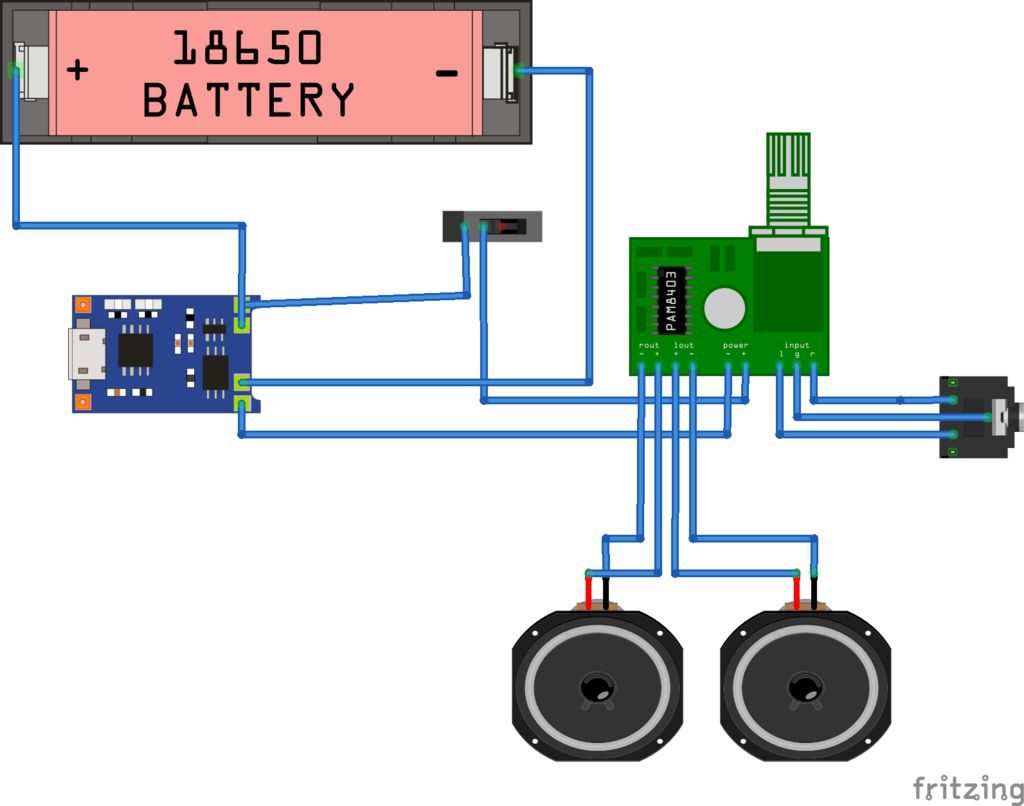

- PAM8403 2x3W amp

- 1850 Lithium-ion battery

- TP4056 charge and discharge protection board

- 3.5mm jack

- PCB Switch

- Micro USB breakout board

- 2x3W speakers

- Bluetooth module

TOOLS

- 3D Printer (along with STL files via Thingiverse)

- Soldering iron

- Solder

- Light gauge wire

- Helping hands kit for soldering

- Hot glue gun

- Vernier caliper

Design the Speaker Box

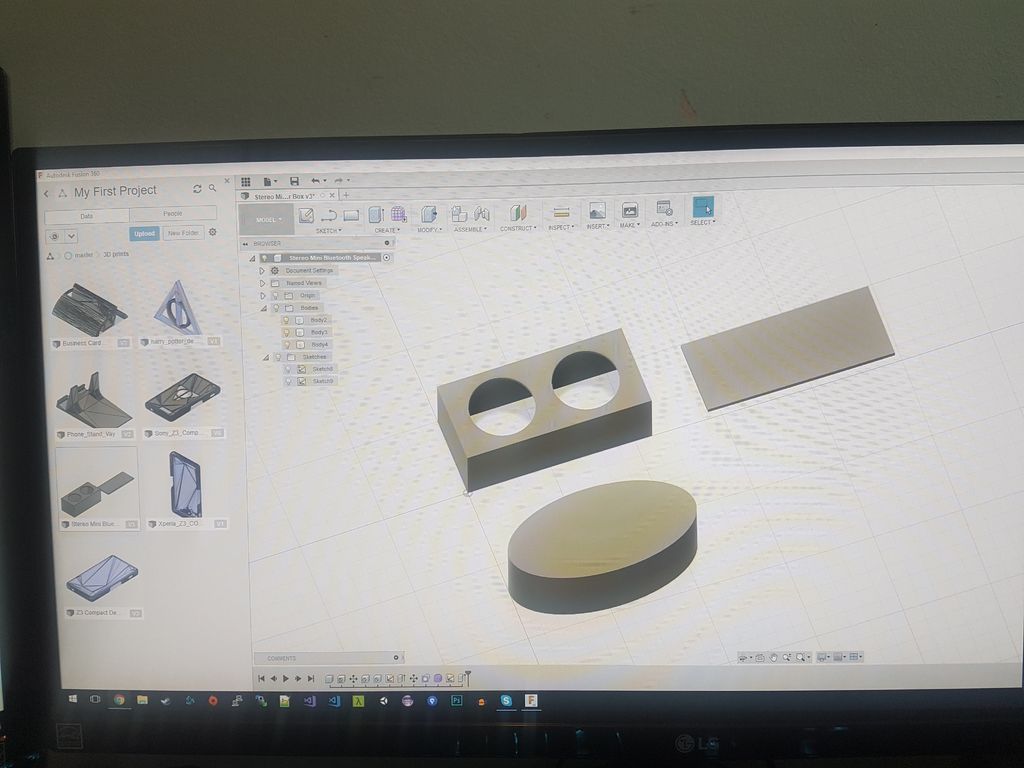

The software used is Fusion 360 and you can get the STL files from Thingiverse. Therefore, make sure that you use the vernier calipers correctly as the measurements are important. So that the electronic component can be assembled properly in the box. Hence, there is no noise and disturbance in the quality of the sound. Print it out: In Bhagwandeens version of mini Bluetooth speakers. The filament used is CC Tree PLA of 1.75 mm, layer height of 0.32 mm and 50 percent infill. The 3D model for the speaker box, designed by the tinkerer on Fusion 360. Therefore it is a relatively quick 5 hour 3D print.

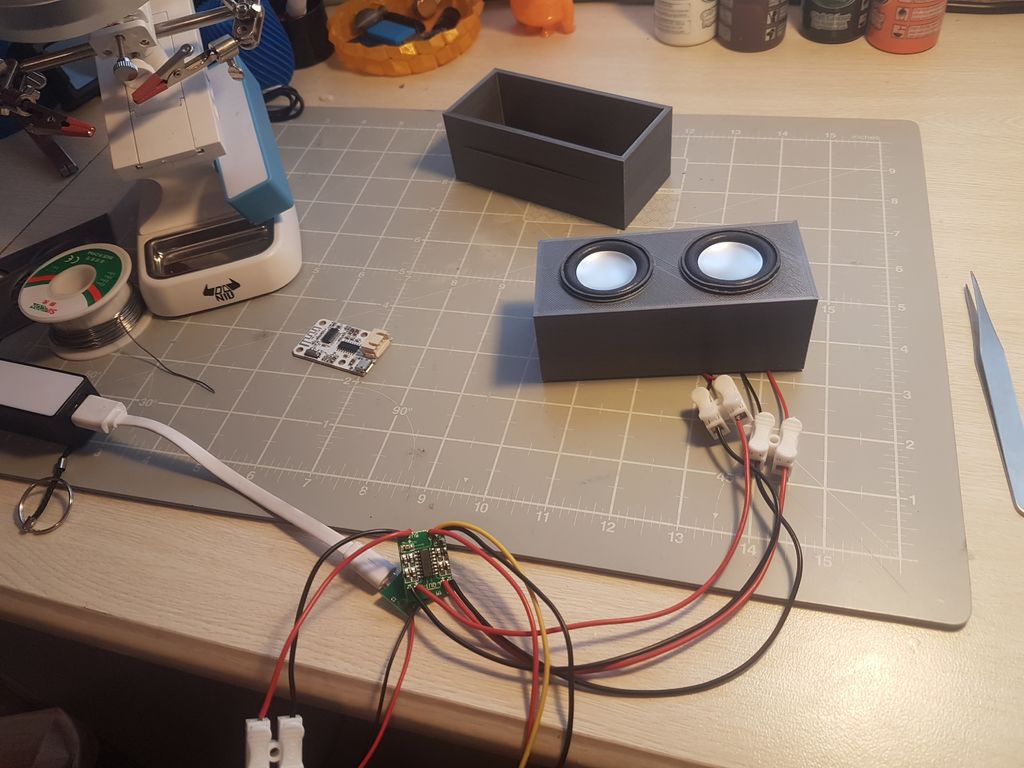

Hence, he also shares the initial mistakes and subsequent redesign. So, that came with developing this project. Obstacles included incorrect measurements, which made it difficult to fit in the speakers. As well as forgetting to print holes for the switch, jack, and micro USB slot. Eventually, Bhagwandeen overcame these issues and was able to build his speakers. Therefore, before going to the further step of soldering the maker recommends testing the electronic components. And also, check whether they are working properly. Then start with the soldering which has to be done accordingly to the below schematic diagram.

After the soldering process simply uses the hot glue gun to assemble the electronic elements into the 3D Printed speaker box. The speaker enclosure is designed in such a way that it is easy to open and shut the box without any problem.

The speaker isn’t extremely loud, but it does produce a fair amount of volume. It’s an intermediate project that does require some time and maker skills, but it also seems like a nice undertaking for a beginner looking to get familiar with soldering, or even a more experienced maker who wants a fun and useful project for the weekend. Either way, you can bring your favorite sounds right to your own DIY speaker box and get speakers of your own designs and you can even customize it. I hope this 3D printed Bluetooth speaker is perfect for music lovers.

So start with 3D Printing right away and know about the latest trends in the industry with Geeetech.

credits: all3dp,instructables.com