Run through your amazing ideas and make the best creative 3D Printable for the upcoming Global 3D Printing Day.

For all the 3D Printing Legends, 3rd December is near and we all are excited for the day. 3rd December is known as the “Global 3D Printing Day” the biggest day for all the 3D Printing Lovers. Gear up for the day and show your best creations of 3D to the world with our amazing contest ‘3D Printing MAKER MOMENTs‘. MAKER MOMENTs is just a new way to make you enjoy 3D Printing and make the Best out of your creativity.You can participate and win the best prices also show off your work to the world. So what are you waiting for? Hurry up to your 3D Printers and let it show the magic?

As the Global 3D Printing day is arriving we would like to share some rare and unknown facts about 3D Printing that you never knew…

1. 3D Printing Started in the ‘80s.

Yepp, 3D printing is older than you might think. In fact, 3D printing has its roots in the 1980s. In 1984, Chuck Hull, invented a process called “stereolithography” which used UV lasers to solidify photopolymer that created 3D parts layer by layer. In 1985, Materialise CEO Fried Vancraen was a young man making his own non-computer “FDM” models. Five years later, he founded Materialise, one of the first 3D printing companies.

2. 3D printing is in the movies you watch.

3D printing fun fact: 3D printers are already being used for movies. Props can take hours of hard work to create and apply. With 3D printing, many of those props can be created and re-created faster, easier, and without starting from scratch. 3D printing techniques have been featured in movies such as IronMan, The Hobbit, Jurassic Park, Avatar, The Muppets, Terminator Salvation, Real Steel, Paranorman, The Avengers and Paranorman.

3. 3D printing was primarily used for prototyping, but is now being used for production-ready pieces.

Taking its roots in manufacturing, 3D printing was primarily used for prototyping products. In fact, large corporations continue to use rapid prototyping to save millions of dollars. For example, Ford is currently using 3D printing to make large selections of its car parts for testing. According to Ford, the company can save up to $493,000 a month of work with this production method.

Getting back to the point though, 3D Printing is increasingly being used to create finished projects. Since 2003, our friends at .MGX by Materialise have been working together with top designers to create lamps and other design objects – objects that are now included in the permanent collections of Museums and art galleries worldwide.

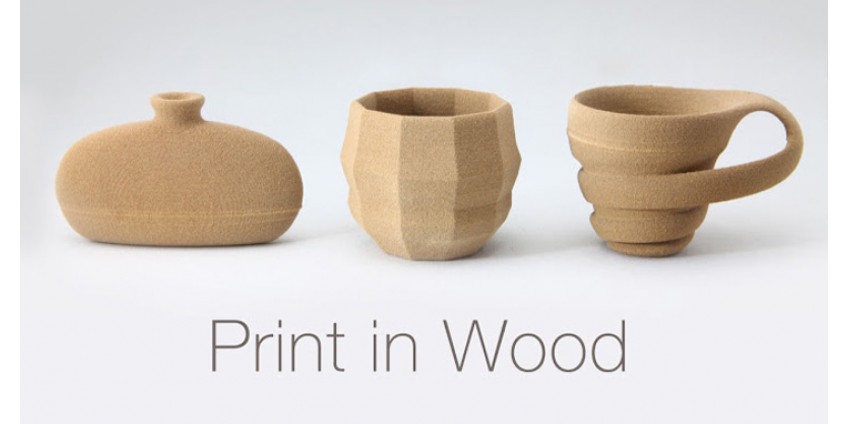

4. You can already print in titanium, ceramics, wood, etc!

Now this 3D printing fact might be surprising: pretty much anything can already be 3D printed. Since the 80s, many new materials for 3D printing have entered the market, including gold, silver, titanium, wood, and ceramics. And these materials are not limited to an elite of industrial giants. Over the last year alone we have seen 3D printed houses, drones, dresses, jewelry and table wear being printed. And many more things can be seen printed in the coming years.

5. 3D printing is launching into space.

NASA researchers are currently working on figuring out how to bring 3D printing technology to space. The idea is to send robots ahead of astronauts to construct buildings and infrastructure on lunar surfaces.

6. 3Doodler Printing Pen

This is a pen that can be used to print 3D objects in the air. The 3D Doodler pen symbolizes a normal pen except it uses 3D Printing material rather than Ink for creating the masterpieces you imagine. For people who cannot yet afford to purchase 3D printers, buying the 3Doodler Pen will sure give you a worthy experience of what 3D printing is all about. You can know the 3D Printing totally from scratch by using this pen.

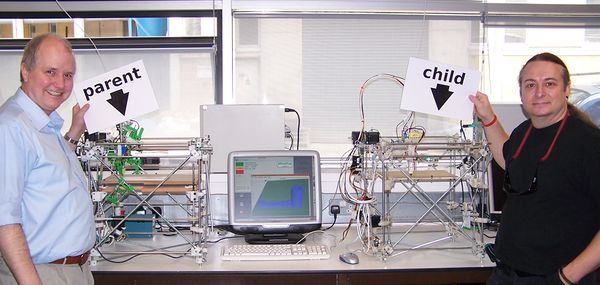

7. RepRap Project

The RepRap Project is a 3D printing open source project teaching how to build a home made 3D printer. The amazing fact is that Building Your Own 3D Printer using the easy DIY steps provided in this open source forum will only cost you about £300. It much explains how the MakerBot 3D printer came into existence.

8. Customization is the next step in 3D printing technology

Soon the question will be what to print rather than how will we print. Customization of every damn thing that we get in the shop or buy online can be done by 3D Printing.Replacement parts, toys, and random designs and schematics found on the internet can all be customized to fit consumer needs. Because the machines can print one piece at a time, this can be done relatively easily. Shapeways, for instance, is a website where customers can connect with designers and order customized products such as jewellery and home decor.

9. People are making all kinds of things with 3D printers

Check out Makerbot’s Thingiverse—the things people create with 3D printers are extraordinarily creative. Its a community where 3D makers from all over the world gather up their 3D Printed creatives.May be get famous too. You can get the Game of Thrones Iron Throne printed to all the crazy stuff that you want even a hair clip.

10. 3D printing is going to cause disruption in many industries

We know 3D printing will upheave mass manufacturers, but what else will the technology affect? New Opprtunities , less work is what will be bought by 3D Printing in the coming future. Educators can print tools or designs in schools. Artists will have a new medium to work with. Healthcare providers can quickly create what they need in-house. Parents will be able to replace toys or broken household items in a matter of hours. Architects can print their blueprints and Fashion designers can show their sample works. Amazing ain’t it!!!

Credit: slideshare.net, 3dprint.com, reprap.org, bluemaize.net, 3ders.org, 3dprintersbay.com, techrepublic.com.