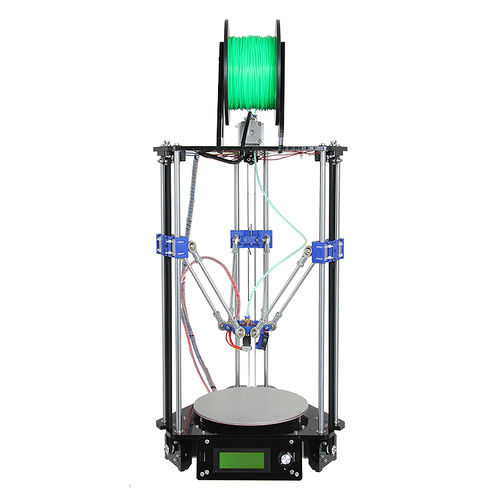

Delta Rostock mini G2

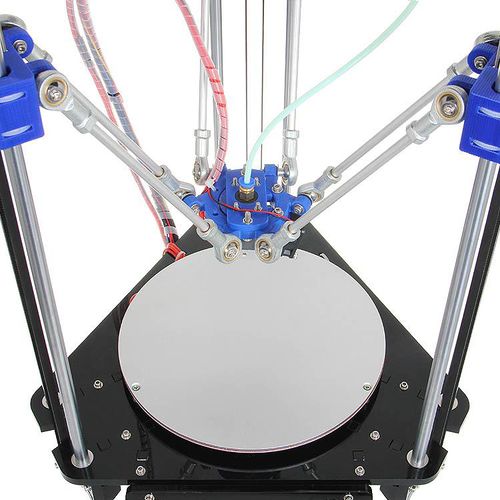

This Rostock mini G2 is a new upgraded delta 3D printer based on the modified design of the Geeetech Delta Rostock mini generation 1.

On the whole, the Rostock mini G2 succeeds the advantages of the previous version like small physical footprint, simple but really rigid frame, high positioning accuracy, flexible effectors, and very similar specification except that we add some innovative design.

This G2 is powered by our newly designed control system—GT2560 that supports 2 extruders and eliminates the complicated wiring of Mega2560+Ramps 1.4 and it is more space-saving and convenient.

We also add an auto-leveling auto-calibration device for G2;which means you do not have to adjust it every time before you start printing, after the first assembly work, you can almost plug and play.

In terms of printing filament, apart from PLA and ABS, G2 supports Nylon and wood filament, which enables more possibilities to create 3D printing project.

This G2 is also improved with a build-on LCD control panel; you can monitor the printing process in real time and with a SD card it can realize stand-alone printing, very convenient.

Contents

Main features

1. New updated control system.

2. Auto-leveling and auto-calibration.

3. More flexible effectors and diagonal rods.

4. More fluent printing process and higher precession.

5. Support PLA, ABS, Nylon and Wood filament.

6. Further simplified structure and enhanced stability.

Specifications

Print Volume: 190 x 200mm

Chassis: laser -cut acrylic plate

The Layer Thickness: 0.1mm

Layer Resolution: 0.1mm

Filament Diameter: 1.75, 3mm

Nozzle Diameter: 0.3, 0.35, 0.4, 0.5mm

Print Speed: 60 to 120 mm/sec

Print Plate Size: 210 x 3mm

Print Plate (Build Platform): aluminum plate + MK2A heatbed

XYZ Bearings: carbon steel

Stepper Motors: 1.8° step angle with 1/16 micro-stepping

Max Heated Bed Temp: about 110 ℃

Max Extruder Temp: about 240 ℃

AC Input: 115V/1.5A 230V/0.75A

Output:DC12V/0-15A

No. of Extruders: 1

Connectivity (Interface): USB, SD Card

Electronics: GT2560

3D printing Software: Repetier Host

CAD Input data file format supported: STL, G code

Client Operating System: Windows, Linux, Mac

Machine Dimensions: 320 x 320 x 870mm

Machine weight:8.5kg

Shipping box dimensions:495*395*195mm

Shipping box weight:9.5kg

Building instruction

For detailed building instruction, please visit here.

Install drivers and software

Install the drivers

Installing Drivers Before printing, you’ll need to install drivers. The kind of driver that a Rostock mini G2 and G2s requires in order to operate properly is called a USB Serial Driver. A USB Serial Driver is software that establishes a COM port.

Plug the USB into a USB port on your computer. Windows Update should automatically find and install the drivers. You’re done with installing the drivers!

Windows Manual Install Note: In some cases the drivers will not install on their own. The drivers for Windows can be found

here.

If the driver was not automatically installed, you may see this screen:

In this case, a. Click “Change Settings…” b. Select “Install driver software from Windows Update”. c. Click “Save Changes”. The FTDI drivers should now install successfully.

Attention: For those having difficulty selecting your COM port

If you have installed the USB serial driver successfully and you are still not able to connenct to your printer in Repetier Host, then windows has not recognized the newly installed driver. In Repetier Host, you may even notice an error message that is similar to this one:

Serial com error:System.IO.Ports.SerialErrorReceivedEventArgs

In some situations, a computer running windows will not automatically recognize a newly installed Serial driver. This means that you will have to update your newly installed driver manually.

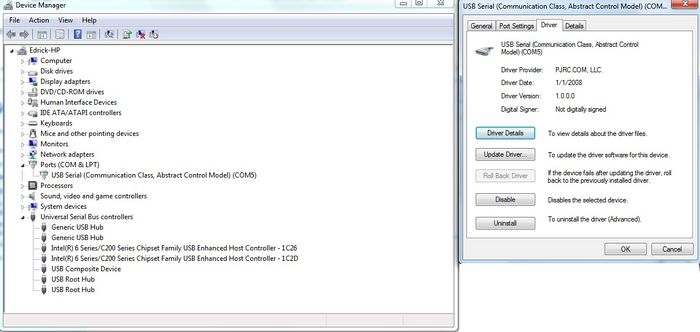

To manually update the driver, you will first need to plug the USB cable into your printer and attache the other end directly to one of your computer’s USB ports. Now, enter the ‘Device Manager’ in Windows and navigate to the hardware category called Ports (COM & LPT) and then left click on it once. You should notice the Ports category expand to reveal a Sub-Category called USB Serial (Communication Class, Abstract Control Model) (COM X); where X is the COM port number. You should be looking for that COM port number in Repetier Host after this procedure is completed; which can be found in “Printer Settings.”

You will need to right click on the USB Serial Sub-class and select proprties. In the drivers tab you will find a selection to update drivers, click on Update Drivers to access the next menu.

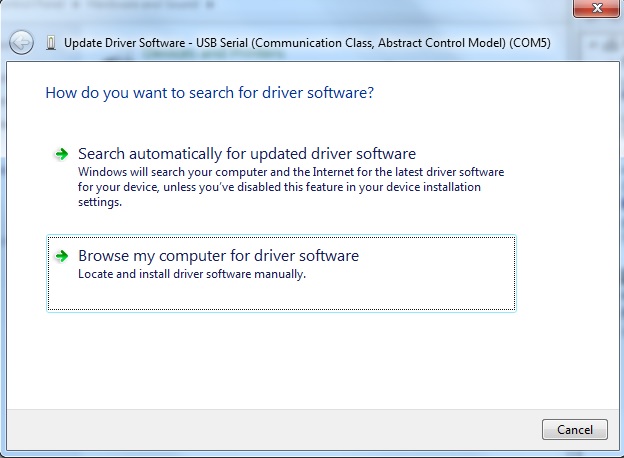

Now that you have selected which driver to update, you will have to tell Windows where the “updated” driver can be found. You should be presented with two options. Select “Browse my computer for driver software” to locate and install the driver software manually.

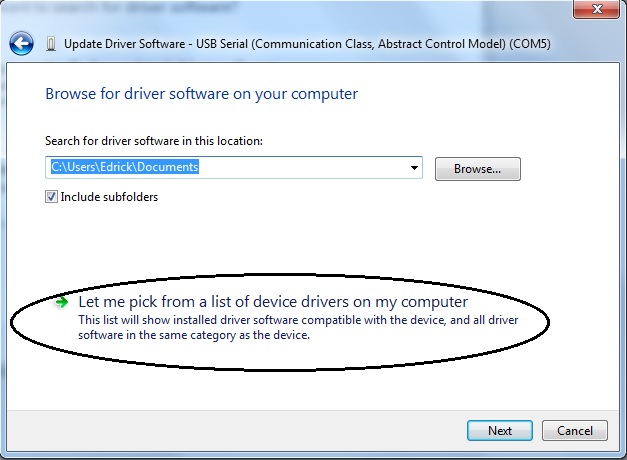

Next, you will be greeted by a menu that allows you to “Browse for driver software on your computer” You will be presented with two choices, select “Let me pick from a list of device drivers on my computer.” Now select the Serial port device and proceed with the installation.

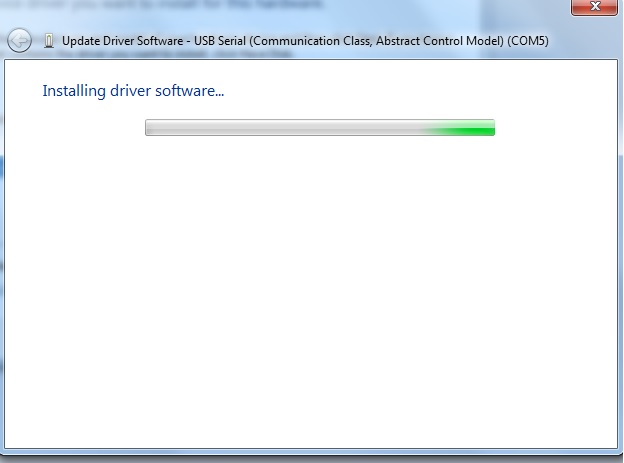

That is pretty much all there is to it. You will then see an installation indicator bar.

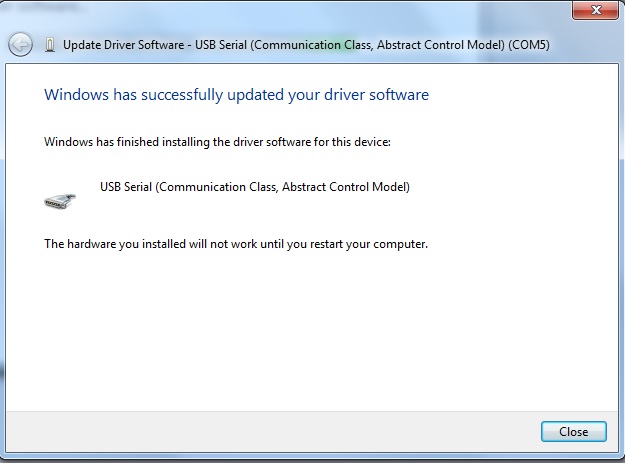

Once the installation is complete you will be notified that “Windows has successfully updated your driver software.” You will be prompted to restart your computer; you should do so.

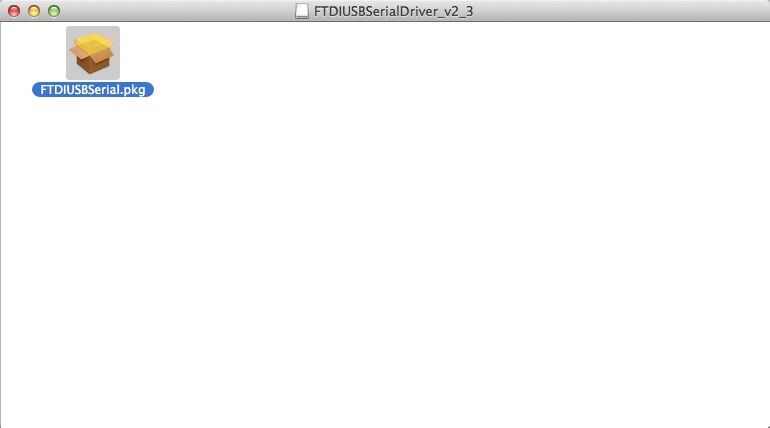

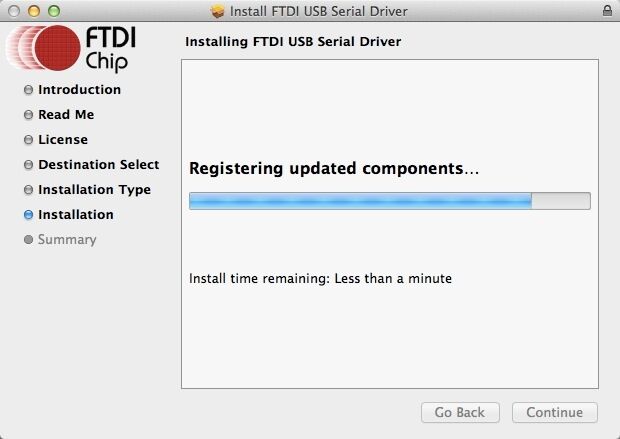

Macbook (OS X) Manual Install

Download link of driver: http://www.ftdichip.com/Drivers/VCP.htm

Download the driver that is compatible with system version.

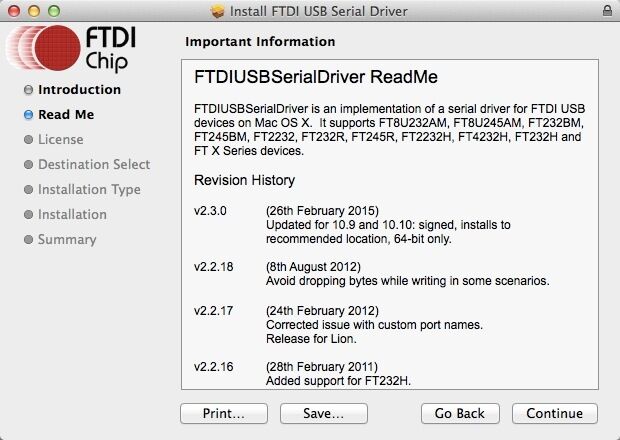

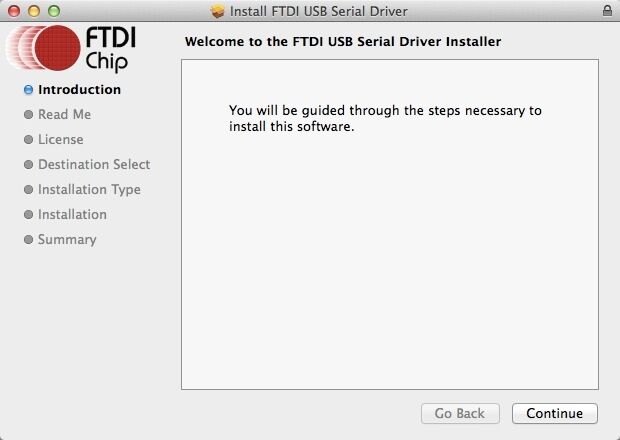

Open the downloaded file, you will see a .pkg file, Open "FTDIUSBSerial.pkg"

Click "Continue" in Instruction.

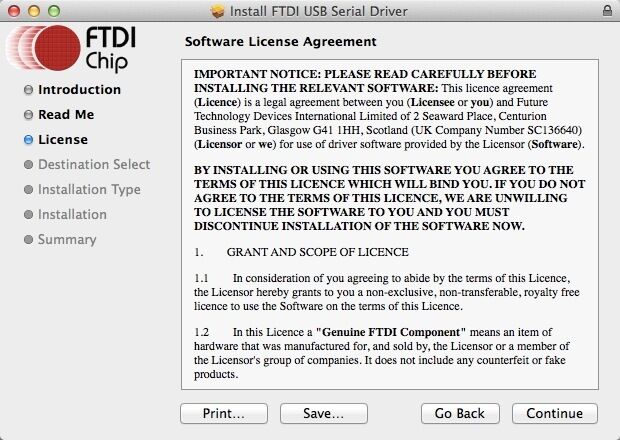

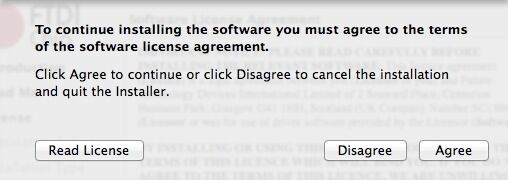

Click "Agree" to continue installation.

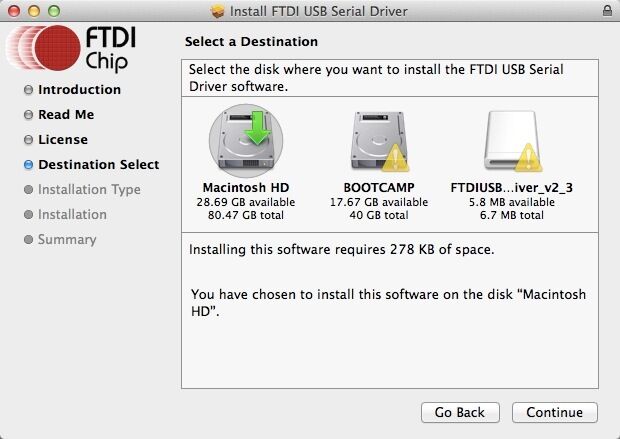

Select the installing destination and click "Continue".

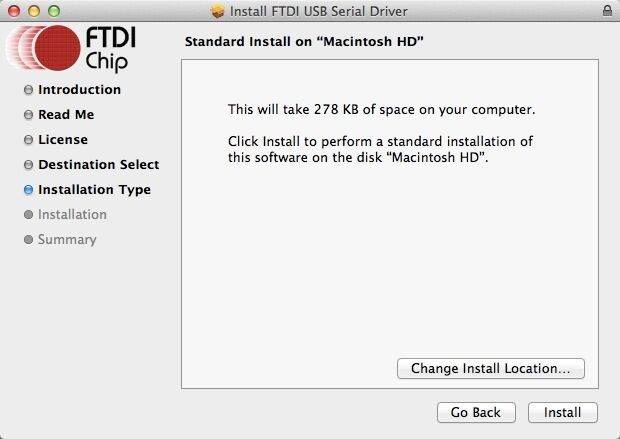

Click "Install" in Installatin Type.

Mac will start to install the driver:

Once your computer restarts, try selecting the appropriate COM port and baud rate in Repetier Host and then connect.

Install Software

we will take windows OS as an example.

To install all required software by Rostock mini G2 and G2s, please follow the steps provided below.

1) Download and install: Media:RepetierGEEEtech.zip

step 1,start the installer,choose the display language. step 2,click next to continue

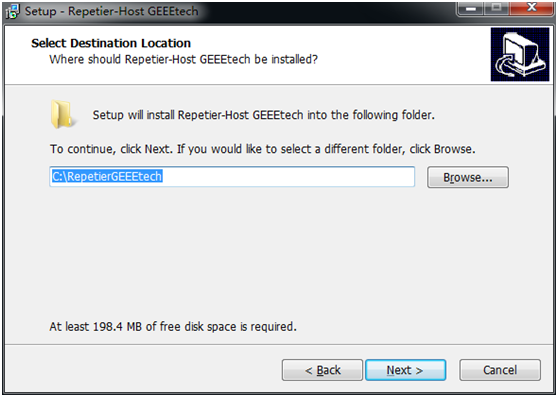

step3,select the destination where you would like to install the RepetierGEtechSetup.

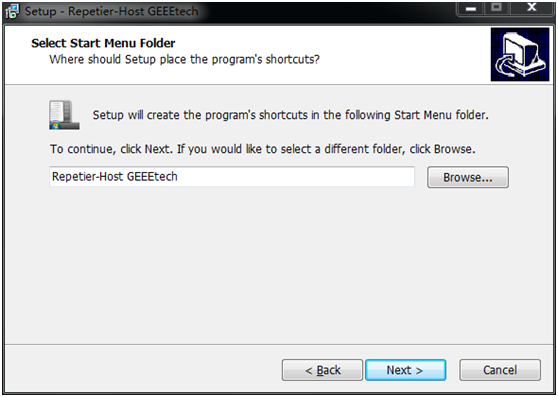

step4,select start menu folder and create a shortcut, click next to continue.

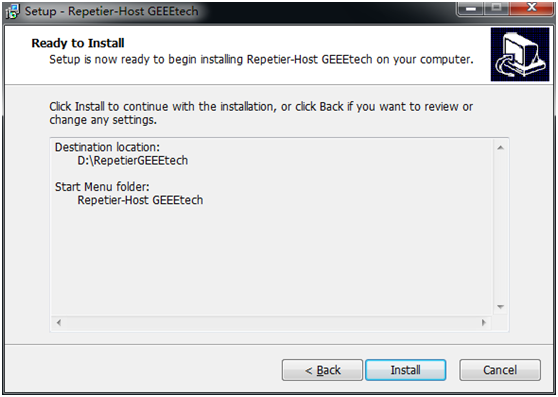

step 5,get ready to install. Click install.

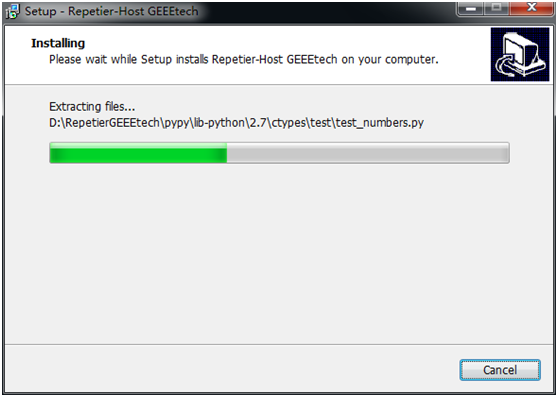

step 6,wait about half a minute while installing. The green bar will show you the rate.

step 7,set up has finished the installing, you can choose to launch it immediately or exit out.

2) Plug the power cord into a wall outlet and the USB cable into a USB port on your computer. Windows should detect your motherboard and assign the appropriate driver.

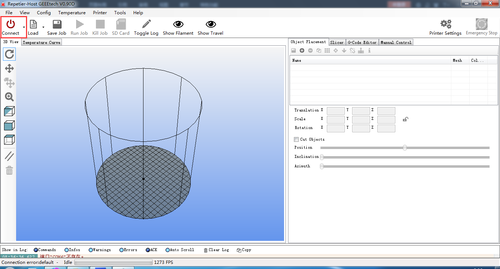

3) Open Repetier Host and Connect to your Rostock mini G2 and G2s!

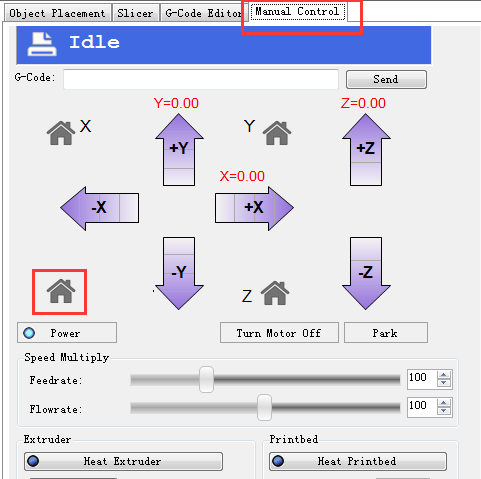

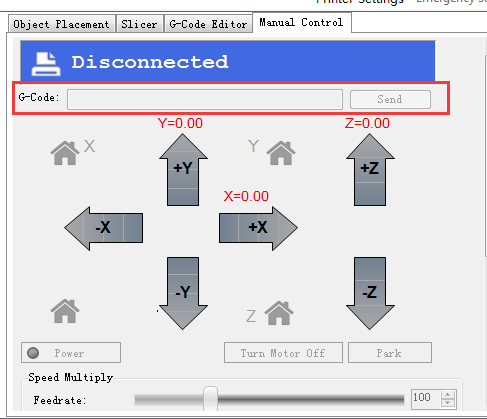

Click on the Manual Controls Tab and click in a direction X or Y to test your connection. If you are having difficulty connecting, please review the following supportive documentation: Installing Drivers and How to connect.

Please note that if you have difficulty connecting, there might have been an issue with the installation process. Ensure that the following have been installed:

Download and install the Serial Driver.

Download and install Microsoft .netFrameWork 3.5

In Mac, you can download Repetier for Mac" at:

After downloading, open "Repetier-Host-Mac_56.dmg",then you will see the icon of "Repetier Host", open it.

How to set up

Printer setting

Step1. Connect the USB to your Rostock mini G2 or G2s and power it up. You can see the LED lights and fan come to life, you may be able to hear the motors idling.

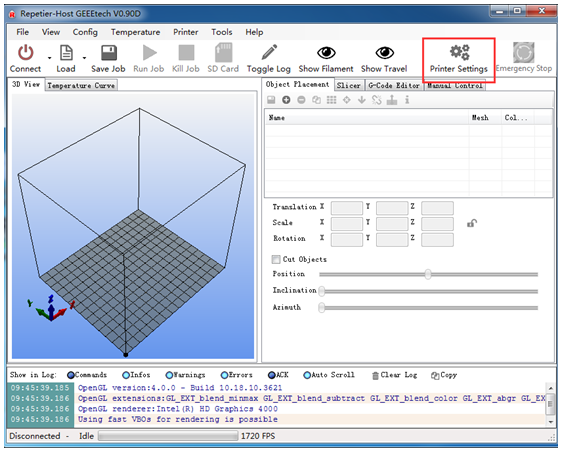

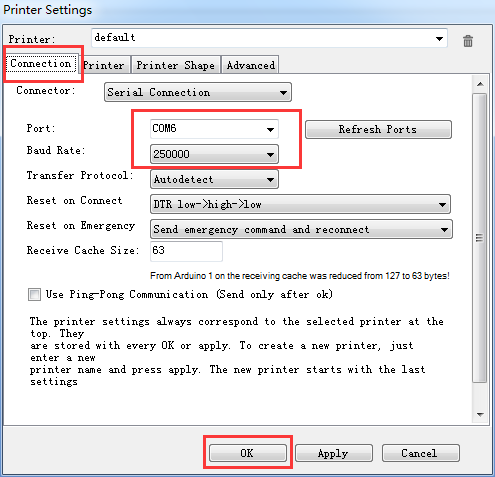

Step 2. Open Repetier Host and ensure that you have a valid port selected for communications. To do this simply, click “Printer Settings” in the upper right-hand corner to bring up the printer settings menu.

Step 3. Choose the Connection menu to select the COM6 port and the Baud rate 250000. Click OK to continue.

If you can not fond the COM port, click “refresh ports” and see if it appears. (It is usually the last one; you can check the device manager to see which port it is). PS: if you still cannot find the port, please re -install your USB driver.

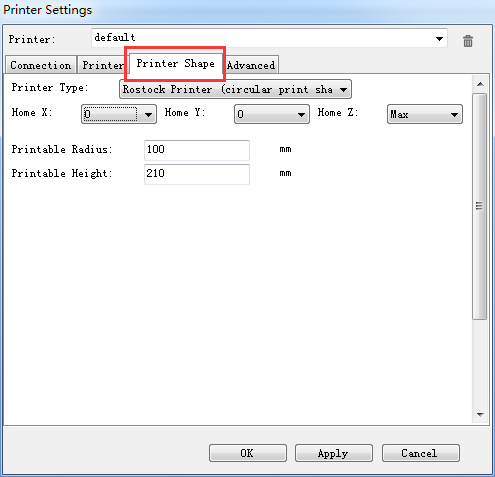

Step4

Choose printer shape. This is very important. Choose printer type as Rostock Printer(circular shape)

Home X: 0

Home Y: 0

Home Z: Max

Printer Radius: 100mm

Printable height: 210mm

Step5. Hit "connect" in the upper left-hand corner. You should see the details of the connection in the console window in the bottom section of the screen.

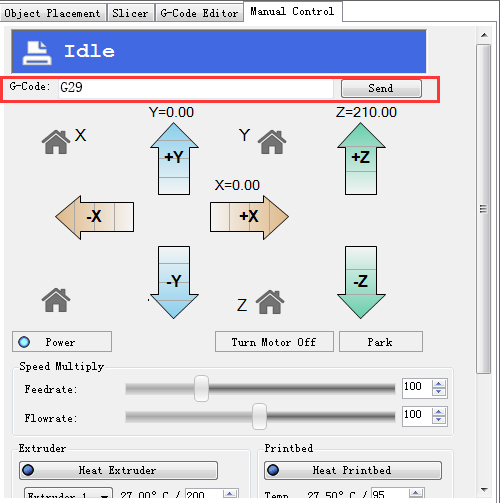

Step 6. Go to the Manual Control and click the home icon.

slic3r configuration

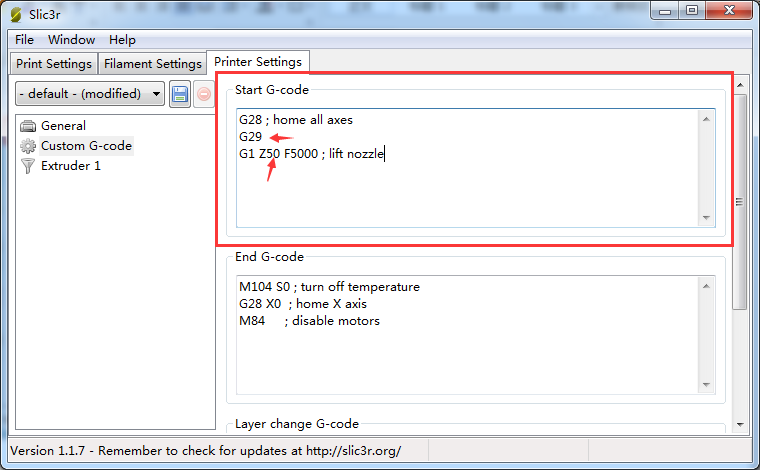

Start G29 Command

Thoughg we have added an auto-leveling probe for the Rostock mini, but generally there is no G-gode in the sli3er, so we need to add the G29 command to the sli3er.

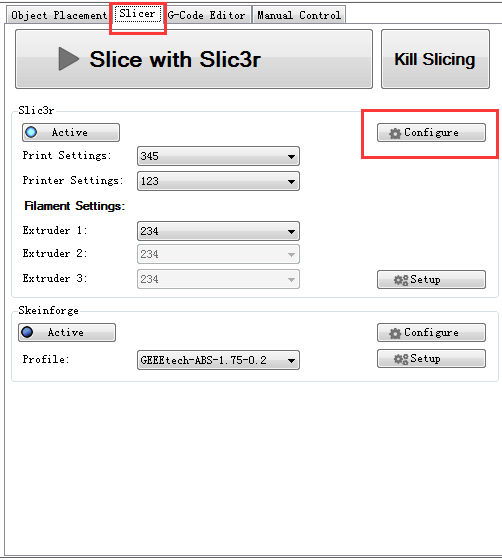

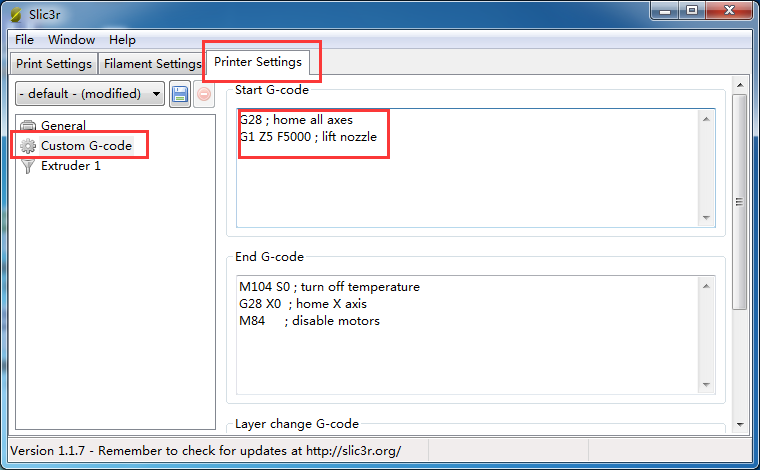

Step1. Start G29 command in Slic3r.

Click Slicer and configure, waiting for a minute till the slicer window prompt up.

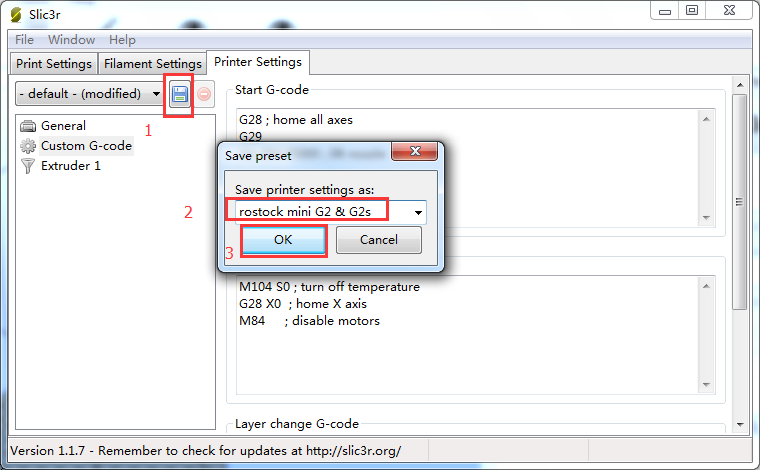

Step2. Choose printer setting-- Custom G-code.

You can see from the start G-code, there is no G29.

So you need to add the G29 after G28 to start it. And change Z5 into Z50.

Save the current printing setting, click “OK” to continue.

In case any cratch caused to your print bed, do not rush to test the auto-leveling command right now.

Printer preparing

1. Adjust the printing bed Put a level meter on the bed when adjusting the 3 screws of the bed to check if it is level.

2. Adjust endstop. Step1. First you need to tighten the screw for each endstop, make sure they reach as long as possibl.

the screw on these 3 carridges.

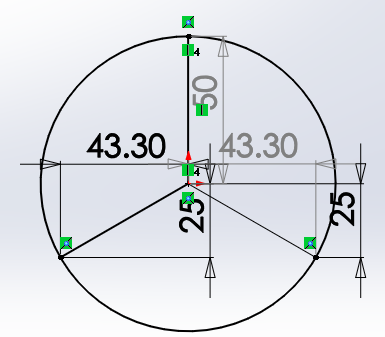

Step2. Set 3 probing points (0,50)、(43.3,-25)、(-43.3,-25), using G-code command to adjust the print head to the 3 points and record the distance between the nozzle and the print surface separately.

1)send command: G0 X0 Y50 Z2, record the distance;e.g. it is 3mm in my case.

2)send command: G0 X43.3 Y-25 Z2, record the distance;e.g. it is 2.7mm in my case.

3)send G 0 X-43.3 Y-25 Z2, record the distance;e.g. it is 2.2mm in my case.

If the 3 numbers differ too much, you can manually move down the print head until the nozzle just hit the print bed, and screw the endstop screw tightly, if the screw has no room to adjust, you need to change the following setting later, record it. E.g. Change 213.5 into 214

455 #define MANUAL_Z_HOME_POS 214

3. Adjust the distance between the nozzle and the print surface, keep the center point and its around point in one plain.

To adjust the distance between the nozzle and the print surface, you need to modify the DELTA_RADIUS (For each 1.0 unit increase or reduce of the DELTA_RADIUS, the z printing volume will increase or reduce 0.2 unit)

122 #define DELTA_RADIUS (DELTA_SMOOTH_ROD_OFFSET-DELTA_EFFECTOR_OFFSET-DELTA_CARRIAGE_OFFSET+2.0)

- If the nozzle touches the center point but not the around points, you should reduce the DELTA_RADIUS

- If the nozzle touches the around points but not the center point, you should increase the DELTA_RADIUS

You may have to adjust this for many times to keep the center point and its around point in one plain. (the distance between the nozzle and the print bed).

Modify the firmware of Delta

We have pre-loaded the firmware to GT2560 before shipping, but as this is a DIY printer, there may be some subtle difference between each printer, so you need to modify the firmware to fit your exact printer for better printing effect.

1. Download the firmware here. And unzip the zip/rar file.

2. Open Arduino IDE. ( If you do not have Arduino IDE, you can download here.)

3. Drag all the files into Arduino IDE.

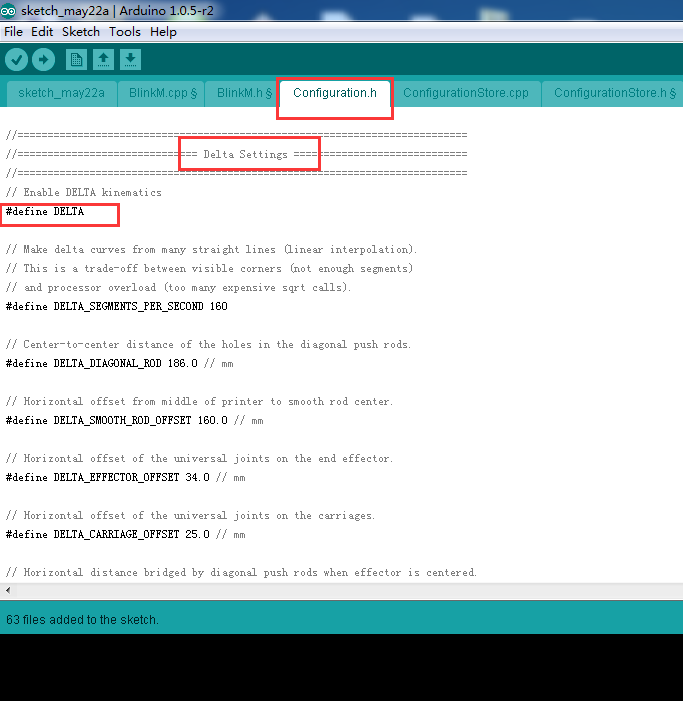

4. Click Configuration.h and find out Delta Settings

#define DELTA and modify the values as below.

Please pay close attention to the red numbers.

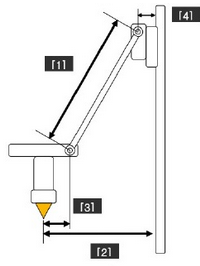

// Make delta curves from many straight lines (linear interpolation). // This is a trade-off between visible corners (not enough segments) // and processor overload (too many expensive sqrt calls). 107 #define DELTA_SEGMENTS_PER_SECOND 160 110 #define DELTA_DIAGONAL_ROD 186【1】 113 #define DELTA_SMOOTH_ROD_OFFSET 160.0 【2】 116 #define DELTA_EFFECTOR_OFFSET 34.0【3】 119 #define DELTA_CARRIAGE_OFFSET 25.0【4】

* To help you better understand the 4 values, you can refer to the scheme.

// Horizontal distance bridged by diagonal push rods when effector is centered.

122 #define DELTA_RADIU (DELTA_SMOOTH_ROD_OFFSET-DELTA_EFFECTOR_OFFSET-DELTA_CARRIAGE_OFFSET+ 2.0) =160-34-25+2

// Print surface diameter/2 minus unreachable space (avoid collisions with vertical towers). 125 #define DELTA_PRINTABLE_RADIUS 83

// use the Z-min, if you connect a mechanical endswitch between Com and NO pins, you do not have to change the setting for the Z-min, however, if you connect it between Com and NC pins, you should change false into true.

322 const bool X_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop. 323 const bool Y_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop. 324 const bool Z_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop. 325 const bool X_MAX_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop. 326 const bool Y_MAX_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop. 327 const bool Z_MAX_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

// Travel limits after homing 365 #define X_MAX_POS DELTA_PRINTABLE_RADIUS 366 #define X_MIN_POS -DELTA_PRINTABLE_RADIUS 367 #define Y_MAX_POS DELTA_PRINTABLE_RADIUS 368 #define Y_MIN_POS -DELTA_PRINTABLE_RADIUS 369 #define Z_MAX_POS MANUAL_Z_HOME_POS 370 #define Z_MIN_POS 0

//these are the positions on the bed to do the probing,the probe positing should not be beyond the printable radius.

382 #define DELTA_PROBABLE_RADIUS (DELTA_PRINTABLE_RADIUS*0.6) 383 #define LEFT_PROBE_BED_POSITION -DELTA_PROBABLE_RADIUS 384 #define RIGHT_PROBE_BED_POSITION DELTA_PROBABLE_RADIUS 385 #define BACK_PROBE_BED_POSITION DELTA_PROBABLE_RADIUS 386 #define FRONT_PROBE_BED_POSITION -DELTA_PROBABLE_RADIUS

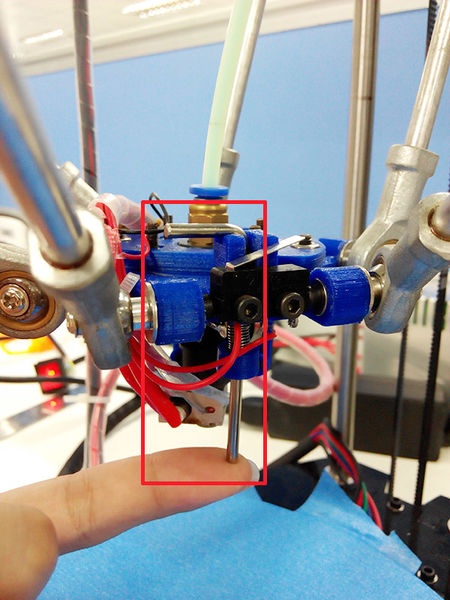

//these are the offsets to the probe relative to the extruder tip (Hotend - Probe), these values are very important, especially the Z_PROBE_OFFSET. You can calculate the Z_PROBE_OFFSET values with this procedure:

Manual y Move the print head down slowly, place the probe at the center of the print bed. When you hear the trigger of the endstop, you can get the coordinate on the LCD or on the Repetier host. In my case, it is 【-20.35,11.75,0.3】, you can add it to the following settings.

389 #define X_PROBE_OFFSET_FROM_EXTRUDER 20.35 390 #define Y_PROBE_OFFSET_FROM_EXTRUDER -11.75 391 #define Z_PROBE_OFFSET_FROM_EXTRUDER -0.3

398 #define Z_RAISE_BEFORE_PROBING 100 //How much the extruder will be raised before traveling to the first probing point. 399 #define Z_RAISE_BETWEEN_PROBINGS 10 //How much the extruder will be raised when traveling from between next probing points

// with accurate bed leveling, the bed is sampled in a ACCURATE_BED_LEVELING_POINTSxACCURATE_BED_LEVELING_POINTS grid and least squares solution is calculated // Note: this feature occupies 10'206 byte 431 #define ACCURATE_BED_LEVELING_POINTS 4

// For delta: Distance between nozzle and print surface after homing. 455 #define MANUAL_Z_HOME_POS 214

Till now, you have finished the edit of the firmware, then, you need to upload the modified firmware into your control board. For those not mentioned just leave them as default.

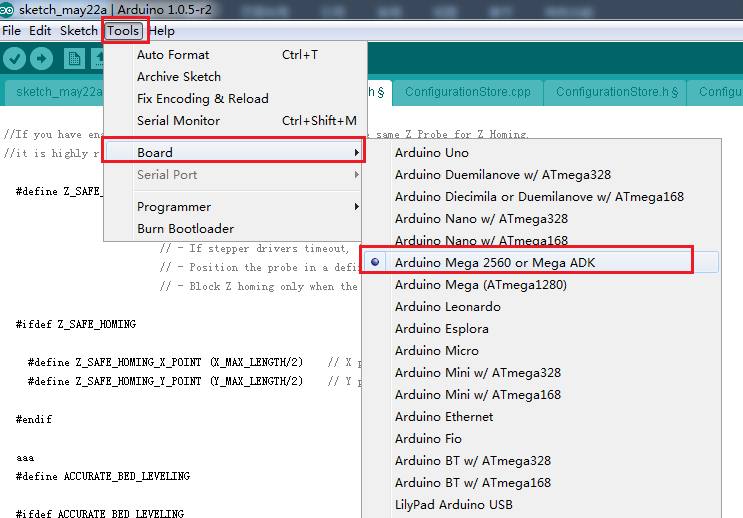

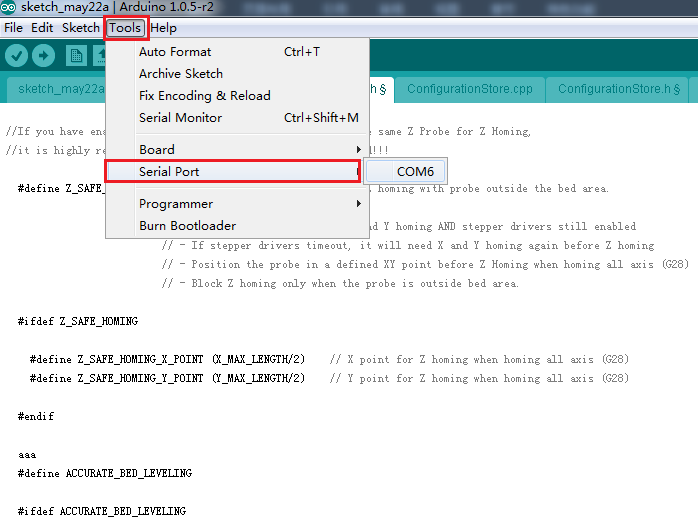

5.Uploard firmware Choose board type.

6.Choose serial port (if you cannot find the serial port, please check the connection of your printer to your computer.)

7.Load in the file you need to burn, Click the “![]() ” button to check if it is right and then click the “

” button to check if it is right and then click the “![]() ” button to upload.

” button to upload.

8.Upon uploading, the LED indicator corresponding to the TX, RX and L on the GT2560 will blink, if they stop blinking, it means the file has been uploaded successfully.

9.After uploading, you can go on to the next step. If you cannot upload, check the dialog box below to identify the problem and solve it. The common mistakes are the wrong select of type of board or serial port etc.

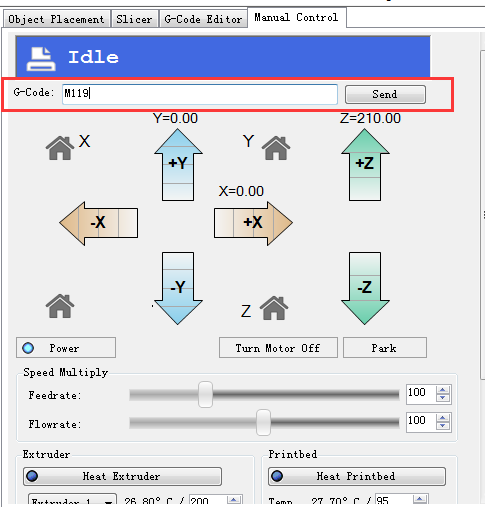

Verify code

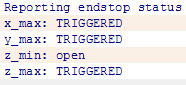

1. verify the endstop Before you risk any damage, you should test if you have configured the z-probe correctly. Send the command M119 to verify the endstop first.

You can see the following message

* x_max,y_max,z_max is for the endstop:

if the endstop is triggered, the feedback is Triggered;

If the endstop is not triggered, the feedback is Open.

z_min is for the probe:

When probe is put down, the feedback is Open;

When probe is hooked up, the feedback is Triggered;

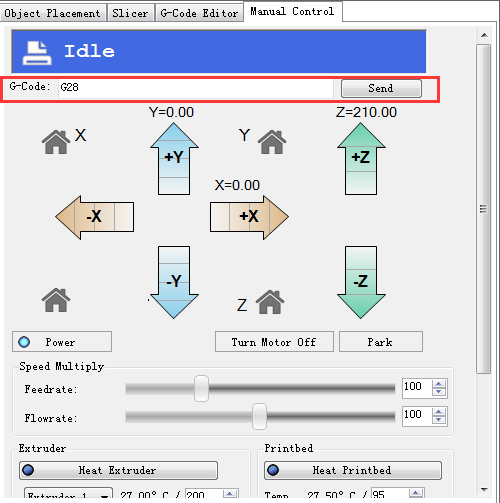

2. Verify Homing Send G28 or click the home icon to homing the printer.

You will see the X/Y/Z raise up till they hit the endstops. Then they will move down a bit and hit the endstops again before they stop (that is to increase the printing precision).

Trouble shooting:

The axis did not stop after hitting the endstops.

Please check if the wire connection of the endstops of X/Y/Z axis matches.

Note: unlike other machines, the origin here is not (0,0,0) but (0,0,MANUAL_Z_HOME_POS)

3. Get the present coordinates

Send M114 command to get the present coordinates after homing, you can get

fw(0,0,MANUAL_Z_HOME_POS) MANUAL_Z_HOME_POS

This is the distance between nozzle and print surface after homing.

Calibration of auto-leveling

Auto-leveling probe is controlled by G29 command. As this is a DIY 3d printer, you may need to help it complete the leveling:

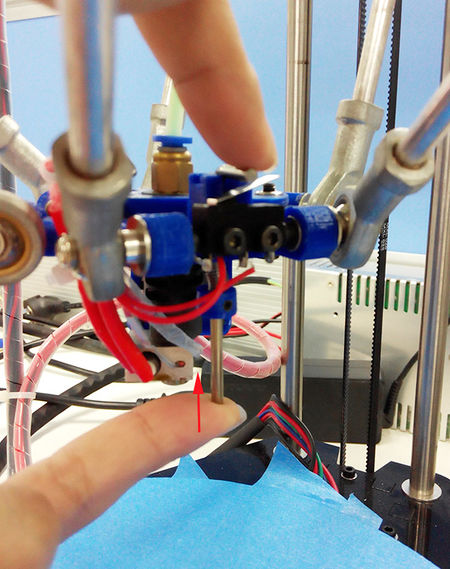

1.You need to put down the auto-leveling probe manualy.

2.Send G29 command.

3.auto-leveling probe will probe the 3 pre-setted probing points. After probing, the print head will raise up a bit and stop.

4.Hook up the probe manualy.

as this calibration needs to be done several time before you can start printing, you can refer to this guide.

1.Manualy put down the probe, then send M119 command to check if the Z-min is open.

2.Send G28 command to auto home the printer.

3.Send G29 command to start the auto-leveling. *there might be collisions, please always be ready to cut off the power supply.

4.After sending G29, the printing head will move down, and hit the probe point setted, after the probing, the printing head will go up.

5.After the leveling, the printing head will raise up and stop, meaning the leveling is finished. You should have the probe back (as the spring on the probe is a bit tight, to make it easier, you can use your finger to push up the probe).

6.Send G1X0 Y0 command to move the printing head to(0,0).

7.Click -Z icon on manual control to move the print head down until it touches the print bed just enough. Send M114 command to get the present coordinates. If the coordinate is (0,0,0), the auto-leveling is successful. If not, you need to modify the Z_PROBE_OFFSET_FROM_EXTRUDER , e.g. Reduce -0.3 to -0.5, and then re-upload the firmware and test again.

8.You may have to test it for more than once, but for the sake of better printing object,please be patient.

9.Once auto-leveling is set up, Hook up the probe manualy. Then you can print your first prints.