Difference between revisions of "Delta Rostock mini G2"

(→Bed leveling) |

(→Printer preparing) |

||

| Line 297: | Line 297: | ||

Put a level meter on the bed when adjusting the 3 screws of the bed to check if it is level. | Put a level meter on the bed when adjusting the 3 screws of the bed to check if it is level. | ||

| − | [[File:PTFE tube1.jpg]] | + | [[File:PTFE tube1.jpg|500px]] |

2. Adjust endstop. | 2. Adjust endstop. | ||

Step1 First you need to tighten the screw for each endstop, make sure they reach as long as possibl. | Step1 First you need to tighten the screw for each endstop, make sure they reach as long as possibl. | ||

| − | [[File:Diagonal rods6.jpg| | + | [[File:Diagonal rods6.jpg|500px]] |

| + | the screw on these 3 carridges. | ||

Revision as of 03:48, 25 May 2015

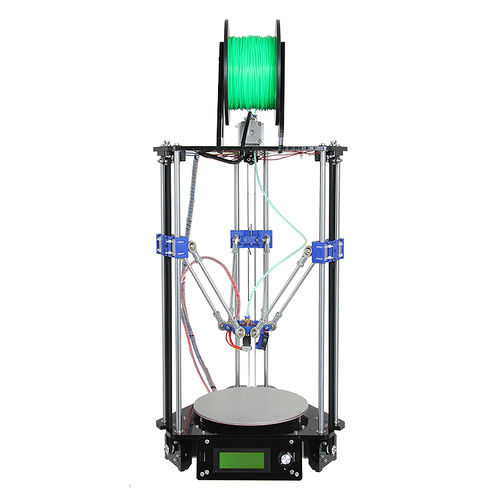

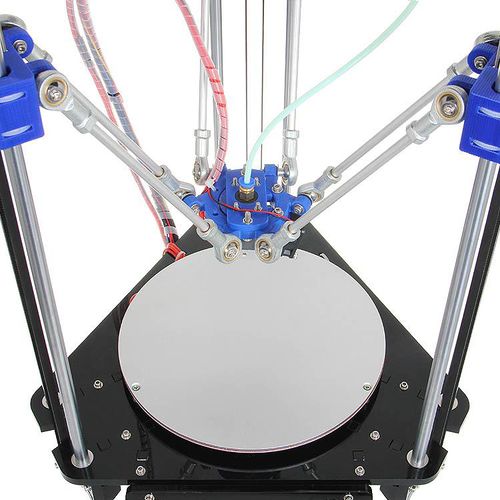

This Rostock mini G2 is a new upgraded delta 3D printer based on the modified design of the Geeetech Delta Rostock mini generation 1.

On the whole, the Rostock mini G2 succeeds the advantages of the previous version like small physical footprint, simple but really rigid frame, high positioning accuracy, flexible effectors, and very similar specification except that we add some innovative design.

This G2 is powered by our newly designed control system—GT2560 that supports 2 extruders and eliminates the complicated wiring of Mega2560+Ramps 1.4 and it is more space-saving and convenient.

We also add an auto-leveling auto-calibration device for G2;which means you do not have to adjust it every time before you start printing, after the first assembly work, you can almost plug and play.

In terms of printing filament, apart from PLA and ABS, G2 supports Nylon and wood filament, which enables more possibilities to create 3D printing project.

This G2 is also improved with a build-on LCD control panel; you can monitor the printing process in real time and with a SD card it can realize stand-alone printing, very convenient.

Contents

Main features:

1. New updated control system.

2. Auto-leveling and auto-calibration.

3. More flexible effectors and diagonal rods.

4. More fluent printing process and higher precession.

5. Support PLA, ABS, Nylon and Wood filament.

6. Further simplified structure and enhanced stability.

Specifications:

Print size (X Y Z): 150 x 150 x 210mm

Chassis: laser -cut acrylic plate

The Layer Thickness: 0.1mm

Layer Resolution: 0.1mm

Filament Diameter: 1.75, 0.3mm

Nozzle Diameter: 0.3, 0.35, 0.4, 0.5mm

Print Speed: 60 to 120 mm/sec

Print Plate Size: 210 x 3mm

Print Plate (Build Platform): aluminum plate + MK2A heatbed

XYZ Bearings: carbon steel

Stepper Motors: 1.8° step angle with 1/16 micro-stepping

Max Heated Bed Temp: about 110 ℃

Max Extruder Temp: about 240 ℃

AC Input: 115V/1.5A 230V/0.75A

Output:DC12V/0-15A

No. of Extruders: 1

Connectivity (Interface): USB, SD Card

Electronics: GT2560

3D printing Software: Repetier Host

CAD Input data file format supported: STL, G code

Client Operating System: Windows, Linux, Mac

Machine Dimensions: 320 x 320 x 870mm

Machine weight: 7.5kg

Shipping box dimensions:

Shipping box weight:

building instruction

For detailed building instruction, please visit here.

install drivers and software

Install the drivers

Installing Drivers Before printing, you’ll need to install drivers. The kind of driver that a Rostock mini G2 and G2s requires in order to operate properly is called a USB Serial Driver. A USB Serial Driver is software that establishes a COM port.

Plug the USB into a USB port on your computer. Windows Update should automatically find and install the drivers. You’re done with installing the drivers!

Windows Manual Install Note: In some cases the drivers will not install on their own. The drivers for Windows can be found

here.

If the driver was not automatically installed, you may see this screen:

In this case, a. Click “Change Settings…” b. Select “Install driver software from Windows Update”. c. Click “Save Changes”. The FTDI drivers should now install successfully.

Attention: For those having difficulty selecting your COM port

If you have installed the USB serial driver successfully and you are still not able to connenct to your printer in Repetier Host, then windows has not recognized the newly installed driver. In Repetier Host, you may even notice an error message that is similar to this one:

Serial com error:System.IO.Ports.SerialErrorReceivedEventArgs

In some situations, a computer running windows will not automatically recognize a newly installed Serial driver. This means that you will have to update your newly installed driver manually.

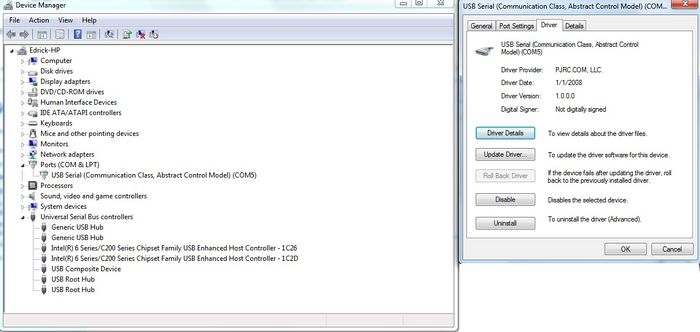

To manually update the driver, you will first need to plug the USB cable into your printer and attache the other end directly to one of your computer’s USB ports. Now, enter the ‘Device Manager’ in Windows and navigate to the hardware category called Ports (COM & LPT) and then left click on it once. You should notice the Ports category expand to reveal a Sub-Category called USB Serial (Communication Class, Abstract Control Model) (COM X); where X is the COM port number. You should be looking for that COM port number in Repetier Host after this procedure is completed; which can be found in “Printer Settings.”

You will need to right click on the USB Serial Sub-class and select proprties. In the drivers tab you will find a selection to update drivers, click on Update Drivers to access the next menu.

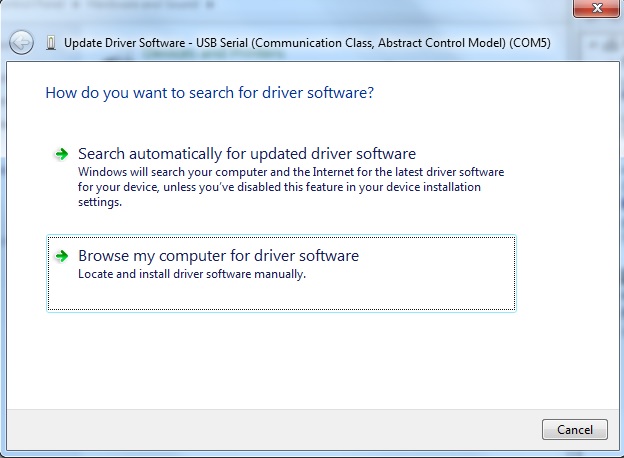

Now that you have selected which driver to update, you will have to tell Windows where the “updated” driver can be found. You should be presented with two options. Select “Browse my computer for driver software” to locate and install the driver software manually.

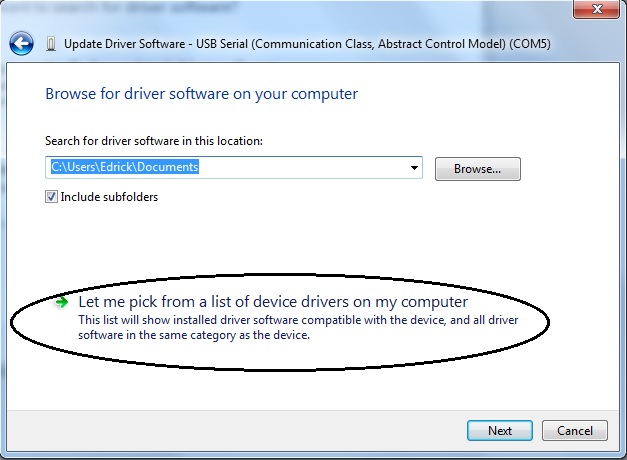

Next, you will be greeted by a menu that allows you to “Browse for driver software on your computer” You will be presented with two choices, select “Let me pick from a list of device drivers on my computer.” Now select the Serial port device and proceed with the installation.

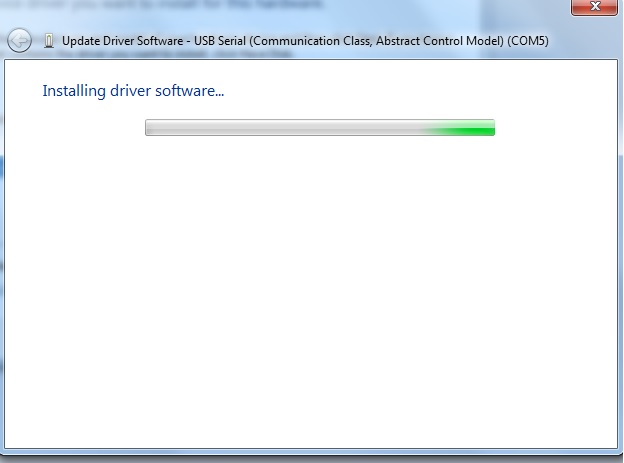

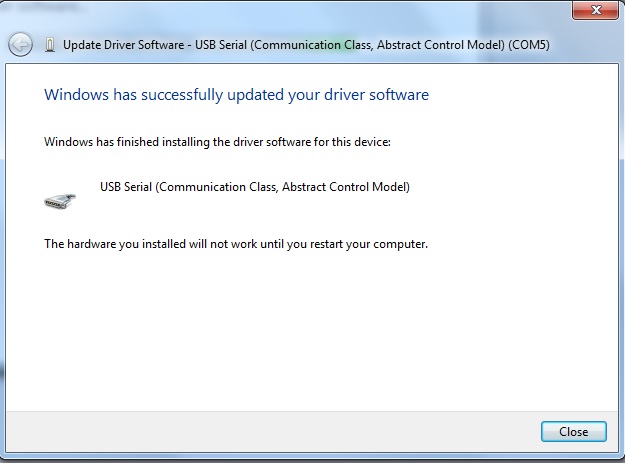

That is pretty much all there is to it. You will then see an installation indicator bar.

Once the installation is complete you will be notified that “Windows has successfully updated your driver software.” You will be prompted to restart your computer; you should do so.

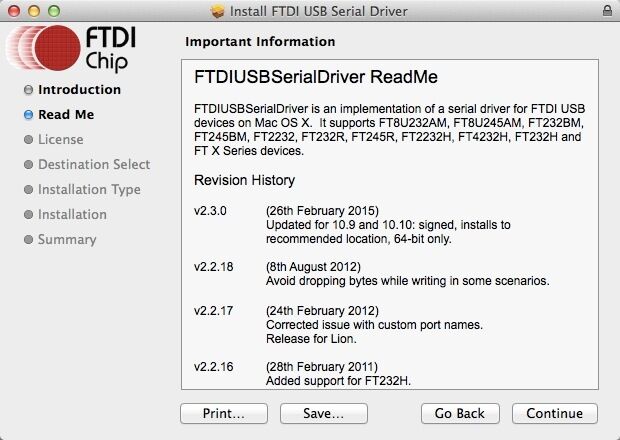

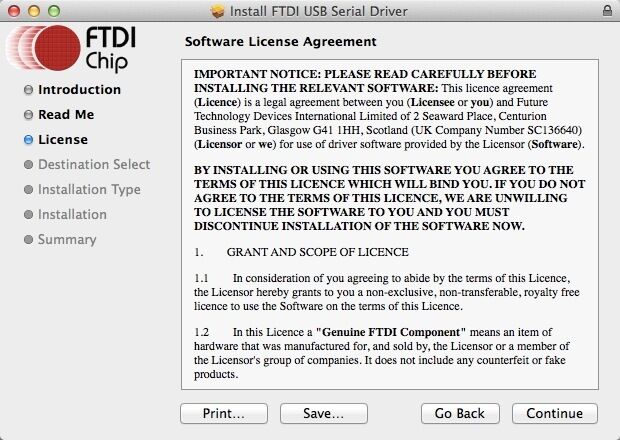

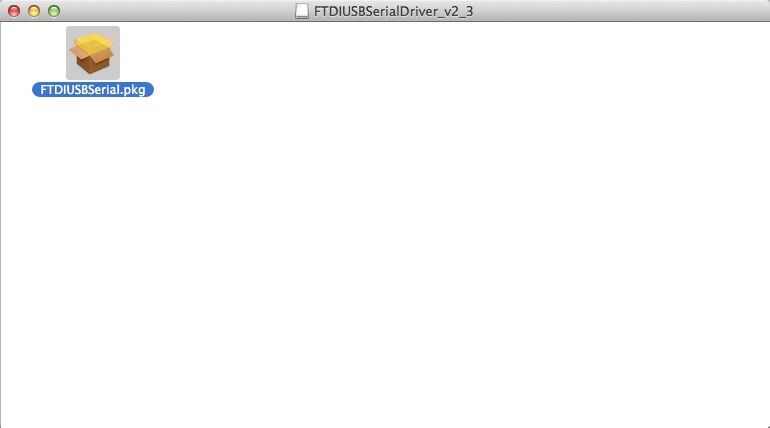

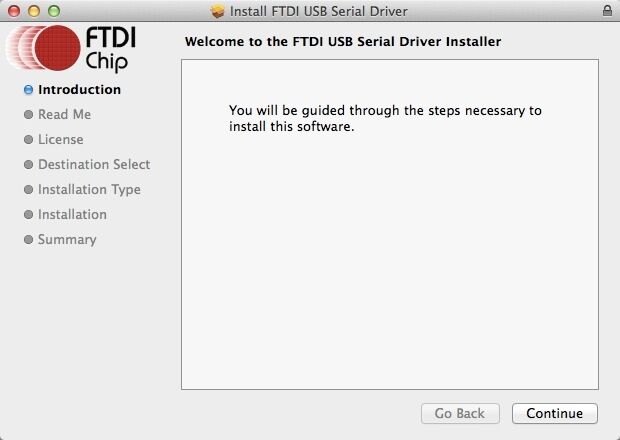

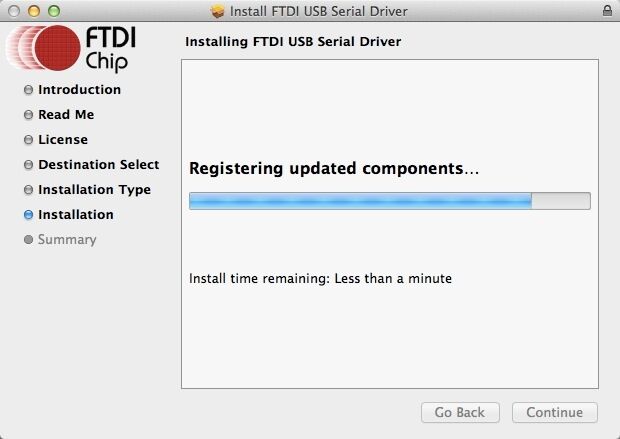

Macbook (OS X) Manual Install

Download link of driver: http://www.ftdichip.com/Drivers/VCP.htm

Download the driver that is compatible with system version.

Open the downloaded file, you will see a .pkg file, Open "FTDIUSBSerial.pkg"

Click "Continue" in Instruction.

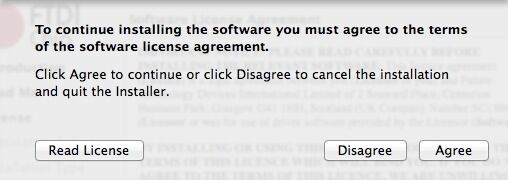

Click "Agree" to continue installation.

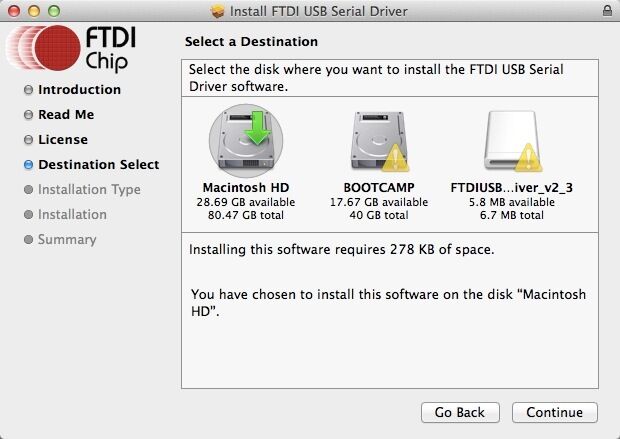

Select the installing destination and click "Continue".

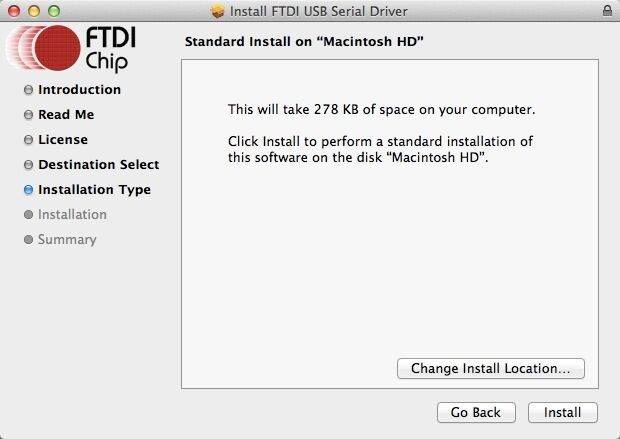

Click "Install" in Installatin Type.

Mac will start to install the driver:

Once your computer restarts, try selecting the appropriate COM port and baud rate in Repetier Host and then connect.

Install Software

we will take windows OS as an example.

To install all required software by Rostock mini G2 and G2s, please follow the steps provided below.

1) Download and install: RepetierGEtechSetup.exe

step 1,start the installer,choose the display language. step 2,click next to continue

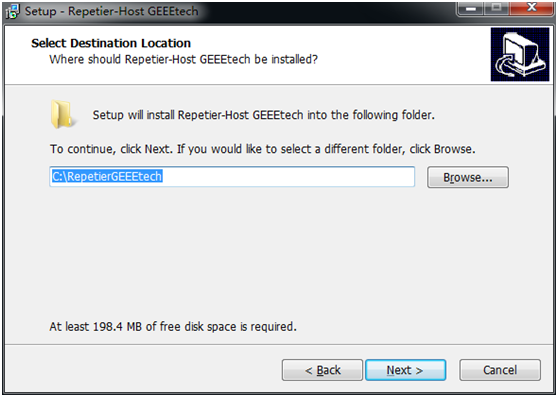

step3,select the destination where you would like to install the RepetierGEtechSetup.

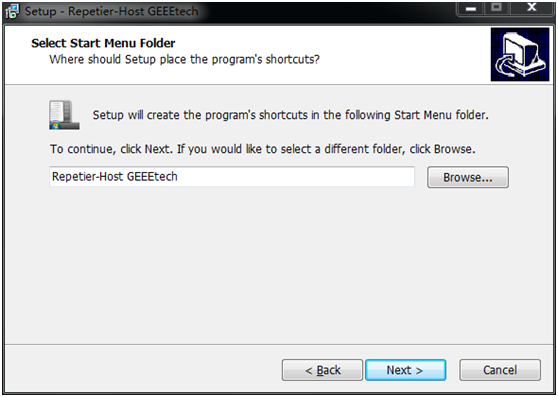

step4,select start menu folder and create a shortcut, click next to continue.

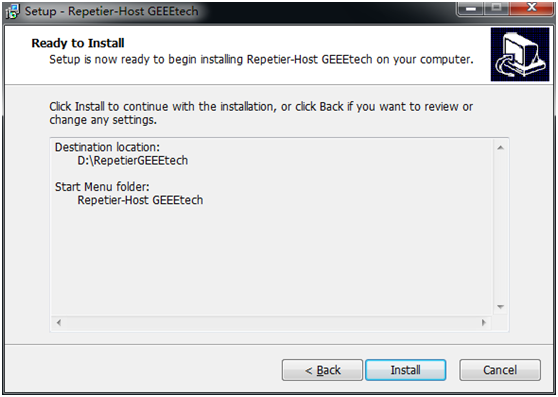

step 5,get ready to install. Click install.

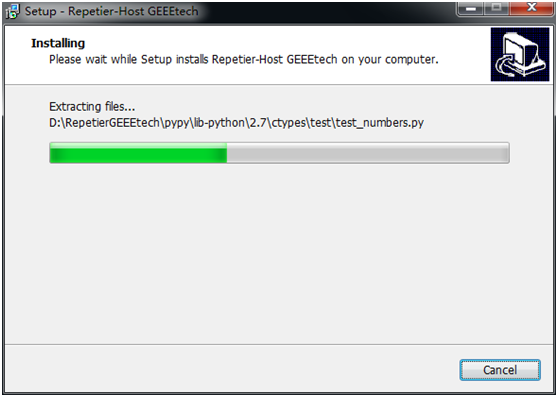

step 6,wait about half a minute while installing. The green bar will show you the rate.

step 7,set up has finished the installing, you can choose to launch it immediately or exit out.

2) Plug the power cord into a wall outlet and the USB cable into a USB port on your computer. Windows should detect your motherboard and assign the appropriate driver.

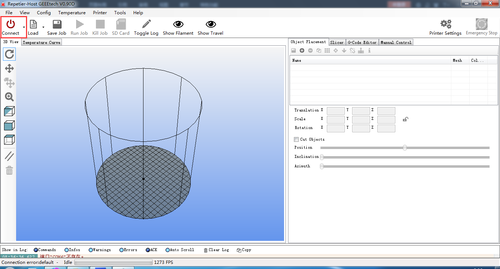

3) Open Repetier Host and Connect to your Rostock mini G2 and G2s!

Click on the Manual Controls Tab and click in a direction X or Y to test your connection. If you are having difficulty connecting, please review the following supportive documentation: Installing Drivers and How to connect.

Please note that if you have difficulty connecting, there might have been an issue with the installation process. Ensure that the following have been installed:

Download and install the Serial Driver.

Download and install Microsoft .netFrameWork 3.5

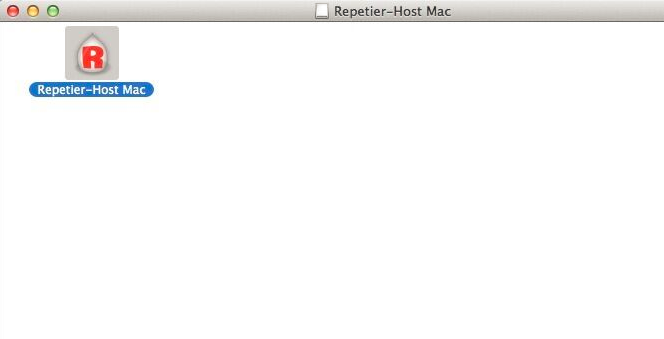

In Mac, you can download Repetier for Mac" at:

After downloading, open "Repetier-Host-Mac_56.dmg",then you will see the icon of "Repetier Host", open it.

How to set up

Printer setting

Step1. Connect the USB to your Rostock mini G2 or G2s and power it up. You can see the LED lights and fan come to life, you may be able to hear the motors idling.

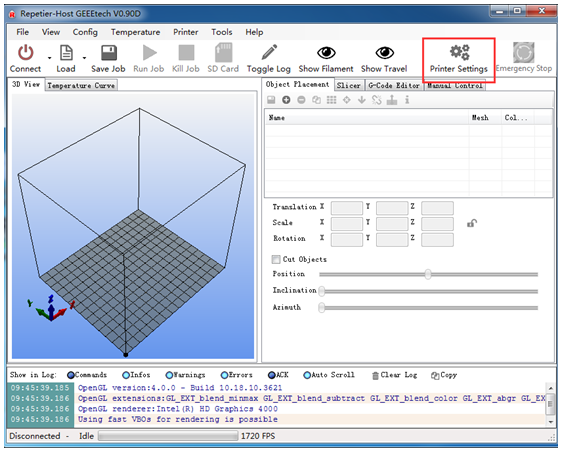

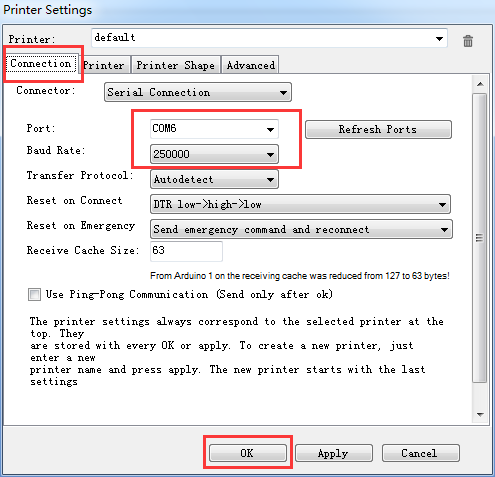

Step 2. Open Repetier Host and ensure that you have a valid port selected for communications. To do this simply, click “Printer Settings” in the upper right-hand corner to bring up the printer settings menu.

Step 3. Choose the Connection menu to select the COM6 port and the Baud rate 250000. Click OK to continue.

If you can not fond the COM port, click “refresh ports” and see if it appears. (It is usually the last one; you can check the device manager to see which port it is). PS: if you still cannot find the port, please re -install your USB driver.

Step4

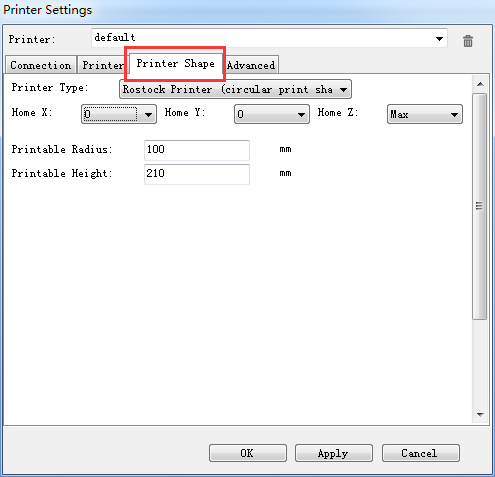

Choose printer shape. This is very important. Choose printer type as Rostock Printer(circular shape)

Home X: 0

Home Y: 0

Home Z: Max

Printer Radius: 100mm

Printable height: 210mm

Step5. Hit "connect" in the upper left-hand corner. You should see the details of the connection in the console window in the bottom section of the screen.

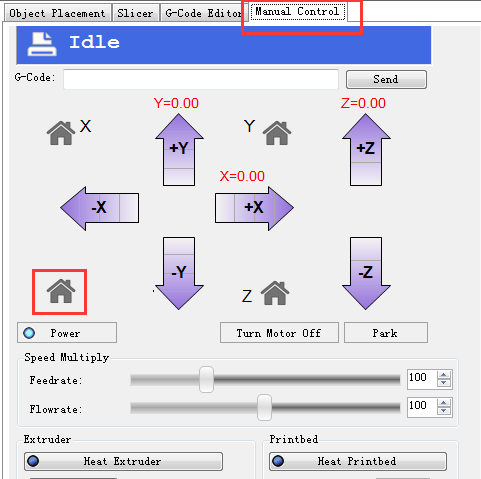

Step 6. Go to the Manual Control and click the home icon.

Start G29 Command

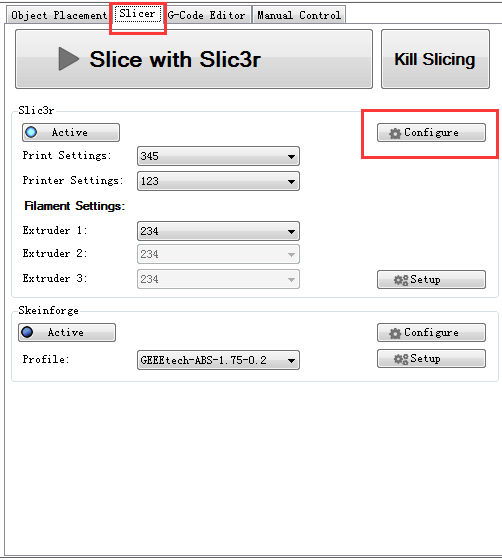

Thoughg we have added an auto-leveling probe for the Rostock mini, but generally there is no G-gode in the sli3er, so we need to add the G29 command to the sli3er.

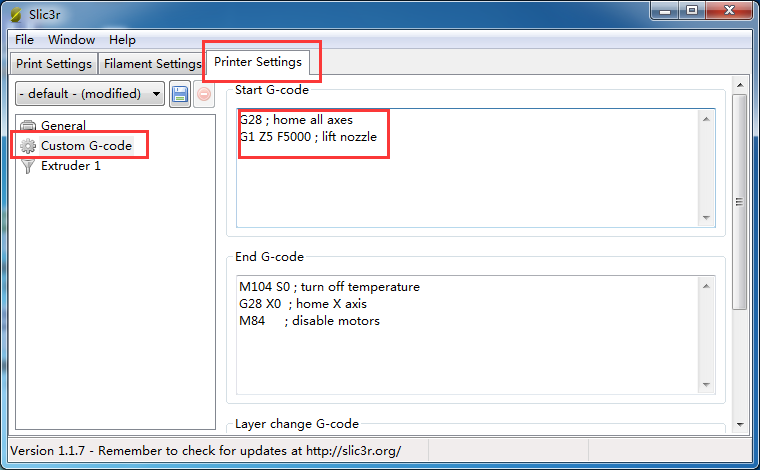

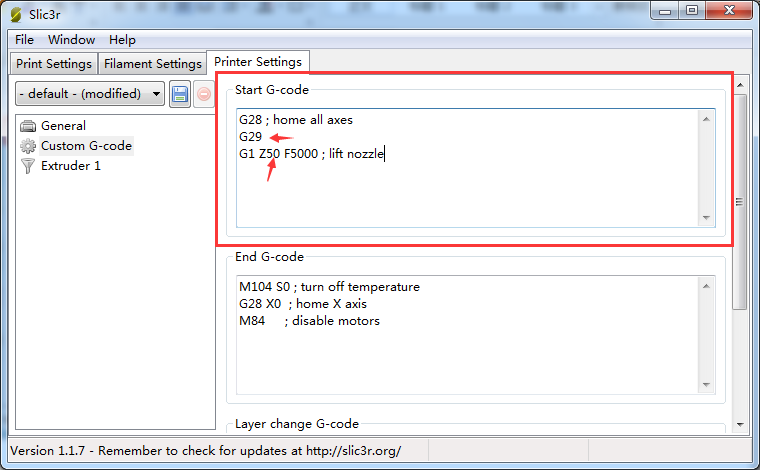

Step1. Start G29 command in Slic3r.

Click Slicer and configure, waiting for a minute till the slicer window prompt up.

Step2. Choose printer setting-- Custom G-code.

You can see from the start G-code, there is no G29.

So you need to add the G29 after G28 to start it. And change Z5 into Z50.

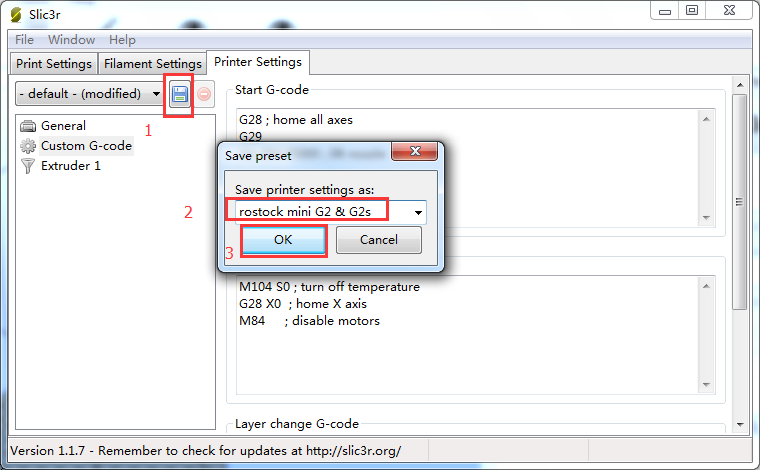

Save the current printing setting, click “OK” to continue.

In case any cratch caused to your print bed, do not rush to test the auto-leveling command right now.

Printer preparing

1. Adjust the printing bed Put a level meter on the bed when adjusting the 3 screws of the bed to check if it is level.

2. Adjust endstop. Step1 First you need to tighten the screw for each endstop, make sure they reach as long as possibl.