Page 1 of 3

FAQ

Posted: Mon Jun 29, 2015 3:53 pm

by zhangxueyou

1. Extruder motor does not work

To protect the extruder motor, the extruder motor can not move unless the temperature of extruder is more than 180 degrees.

2. Extruder motor can move with no filament, but it can not move with filament(moving forward and backward).

1) Check if the nozzle is jammed: If you can extrude the filament with you hand, the nozzle is not jammed.

2) The spring is not tight enough: Raise the temperature of extruder, Use LCD to keep moving the extruder motor(Prepare>Move axis>Move 1mm>Extruder),rotate the screw

properly across the spring until the filament comes out from the nozzle.

- QQ截图20150513154230.png (299.53 KiB) Viewed 34298 times

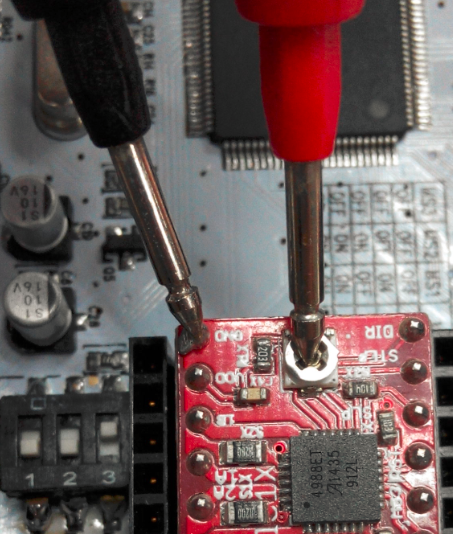

3) Raise the power of extruder motor: There is a screw on motor driver, rotate the motor driver slightly to raise the voltage between screw and GND to 0.9-1V.

- test referring voltage.png (438.77 KiB) Viewed 34298 times

3. The extruder motor does not move with no filament, the temperature has been more than 180 degrees.

1) Check if motor driver(A4988 or DRV8825) is fine:

Turn off the printer, exchange extruder motor driver with a fine motor driver(x motor driver for example). Turn on the printer, home all the axes, if x axis is not moving, we can conclude that the extruder motor driver is dead.

2) Check if extruder motor(

including wire) is fine: Turn off the printer, unplug the filament, plug

extruder motor wire to x motor slot(Assume x motor driver is fine). Turn on the printer, home all the axes, if x axis is not moving, the

motor or motor wire is bad. So the next step is to check if motor wire is fine.

3) Exchang extruder motor wire with x motor wire(Assuming x motor wire is fine), then home all the axes, if x axis is not moving, the wire is bad.

Re: FAQ

Posted: Thu Jul 02, 2015 4:53 pm

by Hock

zhangxueyou wrote:1. Extruder motor does not work

To protect the extruder motor, the extruder motor can not move unless the temperature of extruder is more than 180 degrees.

2. Extruder motor can move with no filament, but it can not move with filament(moving forward and backward).

1) Check if the nozzle is jammed: If you can extrude the filament with you hand, the nozzle is not jammed.

2) The spring is not tight enough: Raise the temperature of extruder, Use LCD to keep moving the extruder motor(Prepare>Move axis>Move 1mm>Extruder),rotate the screw

properly across the spring until the filament comes out from the nozzle.

QQ截图20150513154230.png

3) Raise the power of extruder motor: There is a screw on motor driver, rotate the motor driver slightly to raise the voltage between screw and GND to 0.9-1V.

test referring voltage.png

3. The extruder motor does not move with no filament, the temperature has been more than 180 degrees.

1) Check if motor driver(A4988 or DRV8825) is fine:

Turn off the printer, exchange extruder motor driver with a fine motor driver(x motor driver for example). Turn on the printer, home all the axes, if x axis is not moving, we can conclude that the extruder motor driver is dead.

2) Check if extruder motor(

including wire) is fine: Turn off the printer, unplug the filament, plug

extruder motor wire to x motor slot(Assume x motor driver is fine). Turn on the printer, home all the axes, if x axis is not moving, the

motor or motor wire is bad. So the next step is to check if motor wire is fine.

3) Exchang extruder motor wire with x motor wire(Assuming x motor wire is fine), then home all the axes, if x axis is not moving, the wire is bad.

I try all of this.... extruder still not working...

Re: FAQ

Posted: Mon Jul 06, 2015 2:07 pm

by ric chin

[url]IMG_2890.png{/url]

Can any one tell me why the extruders heads say off at the bottom of this picture?

My extruders have not been working since I have put the machine together, all indications every thing is correct ...firmware uploaded, control board voltage measured correctly at 1.v.

I was told to contact customer service..is there a service ticket number or some sort of identifier?

Re: FAQ

Posted: Mon Jul 27, 2015 11:56 am

by fotomickey

Thanks Eric's FAQ

Further question about Extruder, follow your FAQ can get Delta G2s to manually feed or retract filament by pressing buttons. But when running Slicer job, no filament come-out !? Not sure what I missed.

I'm using 0.3 nozzle with 1.75 PLA filaments. Some G2s & filament Slic3r profile for Slicer will help.

Thanks in advance

Re: FAQ

Posted: Mon Jul 27, 2015 12:02 pm

by Admin

fotomickey wrote:Thanks Eric's FAQ

Further question about Extruder, follow your FAQ can get Delta G2s to manually feed or retract filament by pressing buttons. But when running Slicer job, no filament come-out !? Not sure what I missed.

I'm using 0.3 nozzle with 1.75 PLA filaments. Some G2s & filament Slic3r profile for Slicer will help.

Thanks in advance

hi,can the extruder gear move?

Re: FAQ

Posted: Mon Jul 27, 2015 12:21 pm

by fotomickey

Thanks for quick respond, Yes, both Geeetech and Repeter can move feeder "gear"

forward and backward with filament through hotends. Just can't get Slicer job to print out any filament

Re: FAQ

Posted: Thu Jul 30, 2015 6:27 am

by fotomickey

Yes gear does moved, when commanding from Repetier & LCD on G2S Extruder / Filament can move forward & backward. I suspect the walkthru something to do with Slic3r setup.

Can someone provide some sample profiles for G2S Slic3r setup & 1.75 PLA setup to test on prints ?

Thanks in advance

Re: FAQ

Posted: Tue Aug 25, 2015 6:02 am

by Sandcrab3

It would be awesome if you could post a complete alignment video for the MK8 Extruder assembly.

A step by step procedure to remove/replace the Extruder Tip, tube, spring, etc.

How to clean the tip and Extruder with the PTFE insert.

How to reassemble with how far to screw the extruder tube into the frame, Is the PTFE even with the bottom of the Extruder Tube, do you screw the Extruder Nozzle into the heater block until it's tight, do you screw the Extruder Tube into the block until it's tight against the Nozzle upper end (inside the nozzle block)..... things like this.

When it isn't feeding correctly/jamming, etc. and you have to disassemble everything to clean it, NOBODY seems to have posted a complete detailed instruction. Geeetech has a video with an Asian language talking disassembling one and reassembling it but you can't tell if he is giving specifics.

Any help along these lines would be GREATLY appreciated.

Re: FAQ

Posted: Tue Aug 25, 2015 6:04 am

by Sandcrab3

It would be awesome if you could post a complete alignment video for the MK8 Extruder assembly.

A step by step procedure to remove/replace the Extruder Tip, tube, spring, etc.

How to clean the tip and Extruder with the PTFE insert.

How to reassemble with how far to screw the extruder tube into the frame, Is the PTFE even with the bottom of the Extruder Tube, do you screw the Extruder Nozzle into the heater block until it's tight, do you screw the Extruder Tube into the block until it's tight against the Nozzle upper end (inside the nozzle block)..... things like this.

Also how far to screw the tensioning spring screw on the top into the frame/spring, and how far into the bottom of spring to insert the Spring Stop Screw.

When it isn't feeding correctly/jamming, etc. and you have to disassemble everything to clean it, NOBODY seems to have posted a complete detailed instruction. Geeetech has a video with an Asian language talking disassembling one and reassembling it but you can't tell if he is giving specifics.

Any help along these lines would be GREATLY appreciated.

Re: FAQ

Posted: Tue Aug 25, 2015 3:06 pm

by Mark