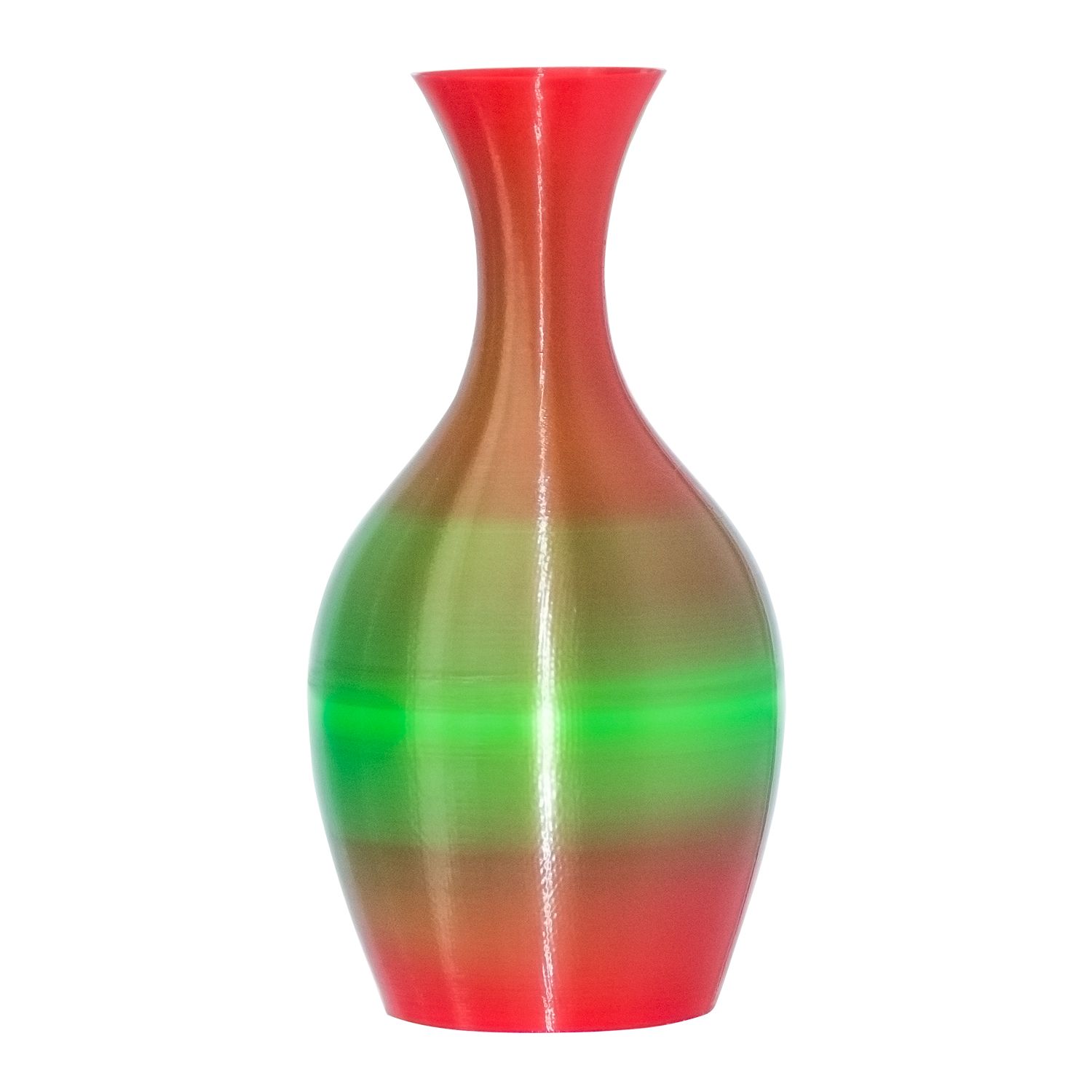

ABS-Like Resin in 3D Printing

3D Printer resin is a key material used in a specific type of 3D printing technology called stereolithography (SLA) and digital light processing (DLP). The main technology in them is to cure and form liquid resin into hard models under ultraviolet (UV) light exposure. 3D printing technology first originated in the 1970s, when it was […]