Guide To 3D Printer Filament PART- III

I know it is the most awaited post which is related to the recycling and storage of the 3D filament. This is the 3rd part of the 3D printer filament guide in the 1st 2 parts I explained about the importance of the 3D material, what is the 3D filament made of, list or different type of filaments, advantages, disadvantages, applications, price, and extrusion temperatures of each and every filament. Now let us discuss the remaining topics.

Can filament be recycled?

Nowadays plastic is one of the important sources required for the living, but plastics are non-biodegradable materials. Some of them might decompose after 10 t0 1000 years or may require more. So it is necessary to recycle the filaments and use it to safeguard the earth, water bodies and animals die due to ingestion and injury after intaking it.

3D printing is expensive but can be managed by recycling the filaments, using recycled filaments. Also, it reduces the cost and helps in the protection of the environment. Now let’s discuss all the methods and equipment used for recycling the filament.

To recycle the filaments mainly requires 2 things one is the Shredder and the other is Extruder. Before starting with these 2 you need to collect all the waste 3D filaments, old prints that are of no use. Therefore start recycling of these products that would result in a new spool of the 3D printer filament.

Why Shredder is required?

If the 3D printer hobbyist is more enthusiastic then shredder can built-in home or can buy ready-made that might cost around $250. Some of the best shredder’s are SHR3DIT and Filabot Reclaimer. These are both compatible with all the filaments especially great with HIPS, ABS and PLA.

When the old prints or waste filament is fed into the shredder it breaks the printers into smaller pieces and then grinders it the fed to the extruder. It is a bit tricky processes for the DIYer’s.

Why Extruder is required?

After shredder completes its work extruder comes into the picture. There is any number of extruder: DIY as well as ready-made extruders that might cost around $300. The extruder heats up the filament then provides the shape that can form a spool. Some of the best extruders are Recyclebot or Lyman/Mulier Filament extruder open-source extruders, Filastruder Kit, Strooder, Filabot EX2 filament extruder, FilaFab Extruders, and Noztek Pro.

The Protocycler is the combination of both shredder and the extruder it also comes with computer controls that help to maintain consistency.

Some tips that might help you while recycling process

- Don’t mix out all the filaments of different compositions doing so may result in undesirable prints.

- Don’t mix filaments of different brands, they should be clean and separated before the recycling process.

Now let’s discuss the other main topic that is the storage of 3D printer filament.

How to store a 3D printer filament?

Storing a filament is a big headache because it shouldn’t catch moisture. Why storage is important? In this case, it will become more brittle, they break down when heated up at the extrusion temperature, and makes the filament weaker. The filaments may not provide an elegant, polished, and intact look as before when they come in contact with moisture. Due to this also creates a sizzling sound while printing and clog the nozzle.

Also, filaments should be kept away from the dust so that it shouldn’t result in bad, fail in print and clog the nozzle. Here are some solutions to how to store the 3D printer filaments. I guess these might help you while printing after along time.

Storage boxes

Storage boxes with transparency appearances help to store 3D printer filaments more effectively. The filaments can be protected to overcome outside moisture. And also, transparency helps in determining which color filaments are in which box. To store the filaments it might require huge boxes so that you can at least store more than 2 filaments in a stack. The diameter and height should be more than 40cm each.

Filament Clips

The filament spools can also be stored using filament clips end tip of the filament is clipped so that it shouldn’t catch moist. There are several types of filament clips the most effective will be the one that is clipped to the edge of the filament.

Silica Gel Packets

These packets are the most suitable desiccant packets that are used to remove excess moisture from the filaments also, these can be quickly dried in the microwave and can be reused anytime. The packets are available in different sizes and for single spool around 50grams is enough, for the larger quantity it requires more.

There are color indicators present in it that help to know whether it is saturated or not if saturated than has to be recharged.

Ziplock and Vacuum Bags

Ziplock and Vacuum bags are the most effective airtight container that is cheapest and easiest to store the filaments. These bags also come with double-zipper mechanisms. That assures there will be no excess air and filaments are well protected. Within a single vacuum bag, around 4 filaments can fit.

PrintDry filament container

These are well-known to store a single filament spool and lid of it assure the box is airtight and keeps moist out of the box. A vacuum hand pump is also provided with these boxes to remove excess air and boxes can be stacked to save space.

Polymaker polybox edition 2

The hero among all the storage solutions is polybox from polymaker it can withstand at least 2 spools weighing 750gms or a 3kg spool which also has a hygrometer that checks the moisture inside the container. The spools are mounted on the ball bearing axles and fed to the feeder with rubber coupling on the side and the top of the container. The bottom of the container consisting of 2 desiccant packets that absorb the excess moisture from the container.

The polybox is more advantageous for hygroscopic materials such as nylon or PVA because of these intakes moist quickly. The filaments should be used from inside the while printing need not take out so due to this unique property the filaments can be stored for long.

Lock & Lock container HSM952

Lock & lock containers are very similar to PrintDry solution even its lid is intact with rubber so there will be no moisture inside the box and can contain a 750gm spool with a desiccant packet. These also can be stacked for more space.

DIY filament storage

There are several DIY storage solutions that can be used for both storing and to print directly from the container. These can be modified using any equipment or features you require at that point. But don’t forget to install the spool holding and a coupling for a Bowden Tube. Also, make sure that the containers are huge enough and coupling is airtight to keep the spool safe when not printing.

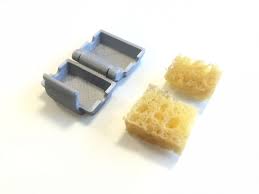

Filament dust filter

The nozzle should also be cared for, not only for the filament. But it may also catch dirt and dust due to which clog may occur while printing. The dust filter is placed between the spool and the feeder to remove the dust that is also clipped on to the filament. The dust filter needs to be printed and put 2 small pieces of sponge on both sides of the dust filter.

Dehumidifiers

A dehumidifier has the name that prevents the humidity. These should be renewed once in every month after the indication. How to renew the dehumidifier? It’s a very simple and easy process it just needs to plug to the power outlet. Therefore, when the silica gel beads change the color. Eva Dry E-333 is the best example of the dehumidifier.

Oven-Drying

The king of the kitchen oven can also be used as the solution for the filament drying. There is one important thing that is when to oven-dry the filament that depends on the Glass Transition Temperature(Tg) of the material. This is the temperature when the filament changes from hard, glassy nature to soft and rubbery material. For example, PLA has a Tg of 60 degrees Celius. If the Tg is greater or higher than 80 it should be kept for an hour at 60-70 degrees, less than 80 than about 30-40 is fine.

I hope the guide to 3D printer filament was helpful and informative. If there is anything you want to know, do comment in the section. If it’s related to 3D printing and stuff I will surely write a blog on it.

Make the best of Geeetech 3D printer only @ Geeetech official site