Tel Aviv University scientists 3D printed heart

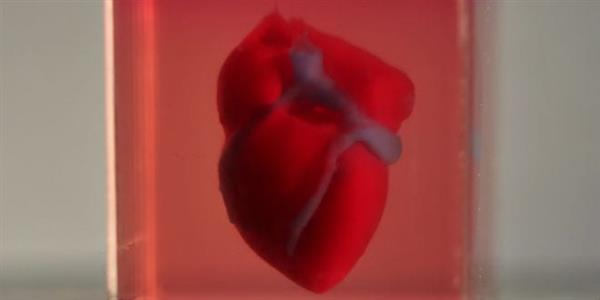

For the first time ever Israeli scientists have created a vascularized 3D printed human heart. Therefore, it combines human tissues taken from a patient, using a 3D printer.

Human Heart: Using Patients Cells

A team of Tel Aviv University researchers revealed the 3D printed heart. That completely matches the immunological, cellular, biochemical and anatomical properties of a human patient. Until now, scientists have been successful in printing only simple tissues without blood vessels.

“This is the first time anyone anywhere has successfully engineered and printed an entire heart. A heart replete with cells, blood vessels, ventricles, and chambers,” said Prof. Tal Dvir of TAU’s School of Molecular Cell Biology and Biotechnology. Therefore, who led the research for the study. He was assisted by Nadav Noor, Dr. Assaf Shapira, Reuven Edri, Idan Gal and Lior Wertheim.

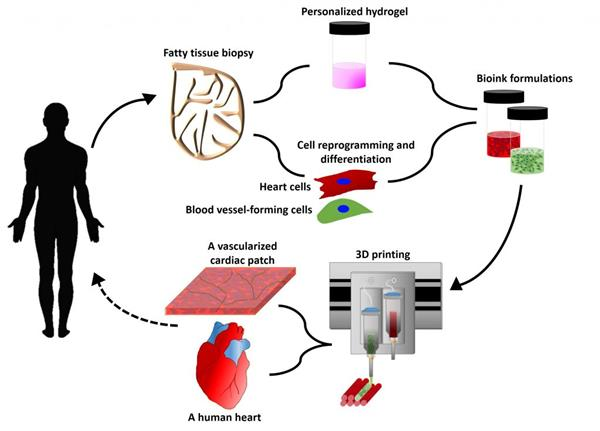

The process involved taking a biopsy of fatty tissue from patients. After which the cellular and a-cellular materials were then separated. While the cells were reprogrammed to become pluripotent stem cells. And therefore efficiently differentiated to cardiac or endothelial cells, the extracellular matrix (ECM). A three-dimensional network of extracellular macromolecules, such as collagen and glycoproteins, were processed into a personalized hydrogel that served as the printing “ink.”

The differentiated cells were then mixed with the bio-inks. As a result, they were used to 3D-print patient-specific, immune-compatible cardiac patches with blood vessels and, subsequently, an entire heart. The 3D printing process takes around 3-4 hours.

First-Ever 3D Heart

“This is the first time anyone anywhere has successfully engineered and printed an entire heart replete with cells, blood vessels, ventricles, and chambers,” said Prof. Tal Dvir of TAU’s School of Molecular Cell Biology and Biotechnology, who led the research for the study. He was assisted by Nadav Noor, Dr. Assaf Shapira, Reuven Edri, Idan Gal and Lior Wertheim.

The process involved taking a biopsy of fatty tissue from patients, after which the cellular and a-cellular materials were then separated. While the cells were reprogrammed to become pluripotent stem cells and efficiently differentiated to cardiac or endothelial cells, the extracellular matrix (ECM), a three-dimensional network of extracellular macromolecules, such as collagen and glycoproteins, were processed into a personalized hydrogel that served as the printing “ink.”

The differentiated cells were then mixed with the bio-inks and were used to 3D-print patient-specific, immune-compatible cardiac patches with blood vessels and, subsequently, an entire heart. The 3D printing process takes around 3-4 hours.

“This heart is made from human cells and patient-specific biological materials. In our process, these materials serve as the bio-inks, substances made of sugars and proteins that can be used for 3D printing of complex tissue models,” Dvir said. “People have managed to 3D-print the structure of a heart in the past, but not with cells or with blood vessels. Our results demonstrate the potential of our approach for engineering personalized tissue and organ replacement in the future.”