ABS vs PLA: Everything You Need To Know About The Two Most Popular 3D Printing Filaments

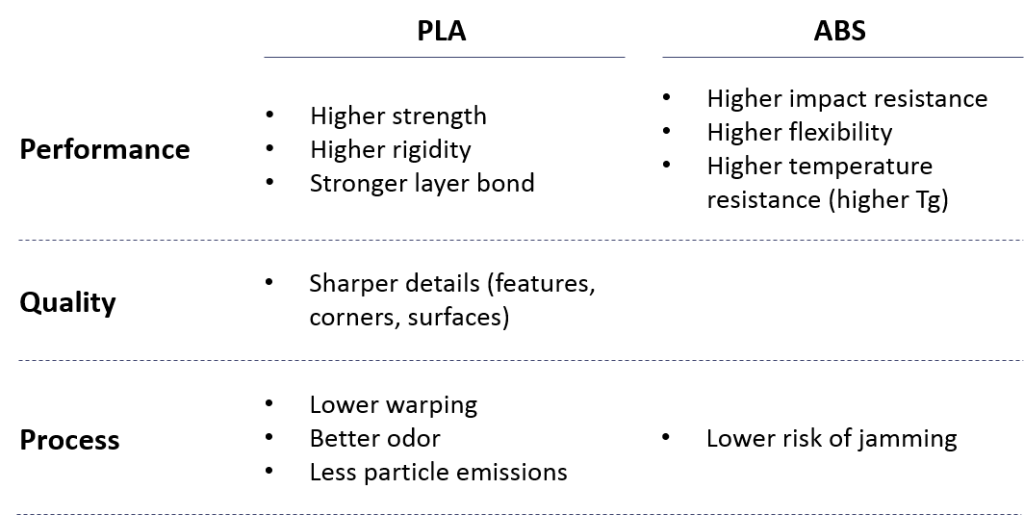

PLA and ABS are no doubt the two most popular filaments and you’ve definitely heard their names thrown about in most 3D printing conversations. Though there is not much of a difference in terms of their efficiency, there are certain factors which separate these filaments in terms of storage, rigidity, smell, and application.

If you’re new to 3D printing(or just generally curious) here’s a rundown of all the comparisons between the two and when you should use them. Happy Printing!

PLA

Polylactic Acid (PLA), one of the most preferred and popular filaments in the 3D printing industry is a biodegradable thermoplastic, made from renewable resources like corn starch or sugarcane. The main benefit of PLA? It’s extremely easy to print. So easy that it is sought after by professionals and beginners alike!

Outside of 3D printing, it’s typically used in medical implants, food packaging, and disposable tableware.

ABS

Another commonly used filament for 3D printing is Acrylonitrile butadiene styrene (ABS). What’s so special about it? Its ability to resist high temperatures. Objects printed with ABS boast slightly higher strength, flexibility, and durability than those made of PLA, at the cost of a slightly more complicated print process. What’s not so special about it is the nasty fumes that are released while printing!

Commonly found in (DWV) pipe systems, automotive trim, protective headgear, and toys like Lego, it is a little more tough in terms of texture!

Both PLA and ABS are thermoplastics i.e. when heated, they become soft and ductile and consequently return to their solid state when cooled. This ability to soften and be processed again is one of the main reason for their demand worldwide.

Storage

You can store both these filaments for a good amount of time. However, under humid and damp conditions, both filaments are bound to lose its efficiency.

ABS – ABS, when exposed to excess moisture, will tend to foam and jet from the tip of the nozzle when printing. This kind of bubbling which occurs at the nozzle can leave it clogged and unfit for use. When it comes to the final print, the results are foggy with a reduced part accuracy which lacks in clarity and quality.

PLA – PLA reacts a little differently to moisture. Apart from the foaming, a slight discoloration can be seen and a cutback in the properties of the printed part. It dries with room temperature and there won’t be a need for an external source. The simple solution? Don’t expose your filaments to air and store them correctly.

For more information on how to store your filaments safely, check out our easy guide- An Easy Way To Store Your 3D Printing Filament

Fumes

ABS – You may have already heard this, but we’ll tell you again-ABS gives out a horrible smell while printing it. Properly ventilated rooms are the solution if you want to rise above the smell. Also, the extruder temperature must be properly set before printing any object.

PLA – PLA being an environmental-friendly material, does not release as many fumes as ABS and the odor is more bearable. The smell, in fact, is a mild and sweet since the filament is derived from sugar and almost smells like candy. A definite improvement over other heating plastic materials!

Accuracy

Dimension wise, both the filaments are able to create distinct perfect parts.

ABS– One of the cons of working with ABS is that if the temperature is not perfectly set it won’t stick to the bed and will end up curling upwards. Apart from this, mixing the mixture with Acetone or a shot of hairspray could help. When it comes to printing sharp objects there may be some inconsistencies in print, but a small cooling fan near the printer will help fix this problem!

PLA – In comparison to ABS, it is resistant towards warping and you don’t need a heated bed since the room temperature is enough for the printing process. Even then, the absence of the heated bed can still allow the plastic to curl up a little on bigger printed parts.

Overall,

ABS – Because ABS is stronger, more flexible and rigid, this filament is undoubtedly preferred by a lot of engineers and professionals from other fields. Unlike PLA, it is resistant to the external factors like heat and distortion. One thing to consider is that while using ABS a heated bed is an important requirement for printers and some printers cannot support ABS without a heated bed.

PLA – Beginner 3D printing enthusiasts and hobbyists will find PLA much more agreeable for small-scale models and designs. Its wide variety of attractive colors also makes PLA popular for 3D printing experiments.After the post-processing, PLA is said to have sharp corners, low layer heights, and increased printing speed.

Doesn’t all this talk about filaments and 3D Printing just make you want to make your own? Check out our Store for a variety of 3D and filaments to suit your need!

Credits- coexllc.com, my3Dmatter.com, pixabay.com, 3dengr.com