New 3D Printed Medical Tool A Breakthrough for ACL Reconstruction Surgery

Although many people may know the 3D printer manufacturer Stratasys as the corporate behemoth that took over MakerBot back in 2013 (Thanks, Print the Legend), their positive influence on the medical and dental industry can not be denied. Over the past couple of years, Stratasys has placed a keen focus on improving the cost and quality of traditional medical tools. From the release of their dental-driven Objet 3D printers to supplying surgeons with realistic heart models to help patients’ lives, Stratasys has certainly made it a mission to innovate the medical and dental industry with 3D printing technology.

Now, Stratasys Direct Manufacturing (an SSYS subsidiary) has collaborated with a new medical company called DanaMed in order to create a 3D printed tool that could change the face of ACL knee reconstruction surgery. A torn ACL, which has caused the end of many a professional athlete’s career, has generally been repaired with the straight-forward, yet error-prone ‘transtibial technique’. While this is the most implemented type of ACL repair, there are obvious disadvantages, such as the difficulty of accurately placing the surgical graft within the natural ACL point. In order to refine this traditional technique, orthopedic surgeon Dr. Dana Piasecki turned to Stratasys Direct Manufacturing and their 3D printing technology to help develop a more successful tool for ACL reconstruction surgery.

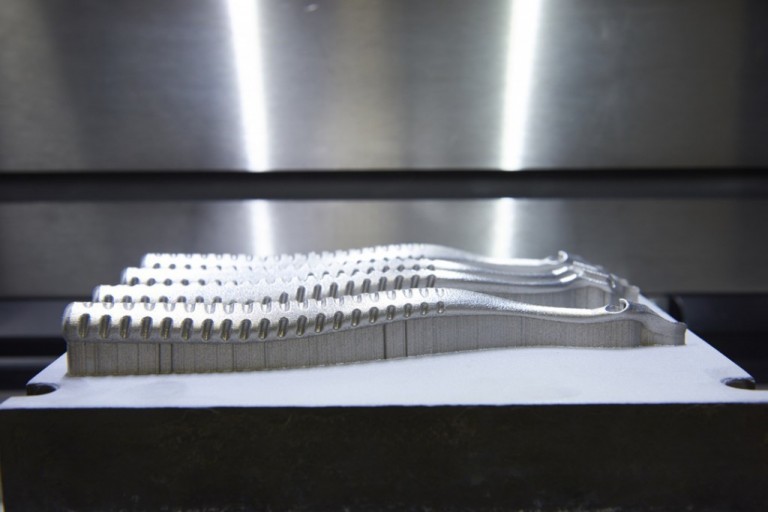

Thus, DanaMed (Dr. Piasecki’s medical company) designed the Pathfinder, a tool that will allow for much more flexibility and accuracy in ACL reconstruction surgery. After creating the first iteration of the surgical tool from plastic and testing it on anatomical models, Dr. Piasecki was directed to Stratasys Direct Manufacturing’s Direct Metal Laser Sintering (DMLS), where the Pathfinder was produced in the biocompatible and mechanically sound Inconel 718 alloy. By utilizing DMLS systems, DanaMed was able to manufacture the tool’s intricate geometry, while keeping the production cost low.

“Pathfinder illustrates how 3D printing is uniquely capable of enabling breakthroughs in medical technology that otherwise would not be possible,” said John Self, Stratasys Direct Manufacturing’s project engineer. “And by offering DanaMed 97 percent cost savings over conventional manufacturing methods, 3D printing has demonstrated its business value in bringing complex, high-quality parts to market.”

Considering that DanaMed is a new venture by Dr. Piasecki and his team, keeping the production cost low was an important factor in the manufacturing of the Pathfinder tool. But the quality of the tool is what makes it a true breakthrough. Although the Pathfinder will need a couple of years to fully integrate itself into the medical field, the resulting surgery technique is already being said to be much easier to perform and has already boasted a 95% success rate thus far. “This surgical tool has turned our vision of transforming ACL reconstruction into a reality faster and someday will hopefully eliminate repeat knee injuries to keep more athletes off the bench and on the field,” said Dr. Piasecki.

—The article is from 3D Printing Industry

Thanks a lot for sharing this with all of us you actually know what you’re speaking about!

Bookmarked. Please also visit my website =). We may have a hyperlink alternate contract among us